Skylight motor beam assembly

A beam assembly and skylight technology, which is applied to roofs, optical observation devices, transportation and packaging, etc., can solve problems such as loose fastening, a large amount of noise beam fixing, etc., and achieve the effect of improving versatility and reducing development costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

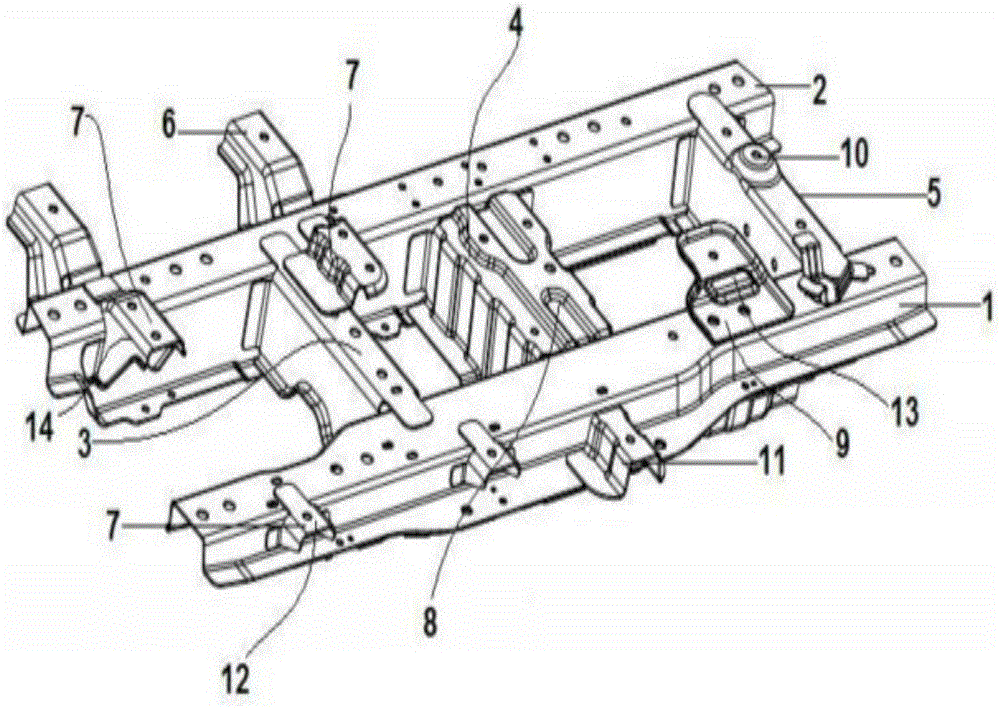

[0020] Such as figure 1 The illustrated embodiment is a sunroof motor crossbeam assembly, including a front crossbeam 1, a rear crossbeam 2, a first longitudinal beam 3 and a second longitudinal The longitudinal beam 4 and the third longitudinal beam 5; the cross-sections of the front beam, the rear beam and each of the longitudinal beams are in the shape of a few characters, and the rear side of the rear beam is provided with 2 supports for installing the motor that extend obliquely to the rear and upward 6. The front side of the front beam, the front side of the rear beam and the first longitudinal beam are equipped with positioning connectors 7 for installing the motor controller, and the second longitudinal beam is provided with 2 strip grooves 8 that match the controller box , The battery support plate 9 is provided on the front beam, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com