A high-efficiency water inlet device for ships

A water inlet device and high-efficiency technology, which is applied in the direction of hull, ship construction, transportation and packaging, etc., can solve the problems of low water inlet efficiency, ship safety hazards, and inability to meet water inlet requirements, etc., to achieve efficient water inlet and improve water inlet efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

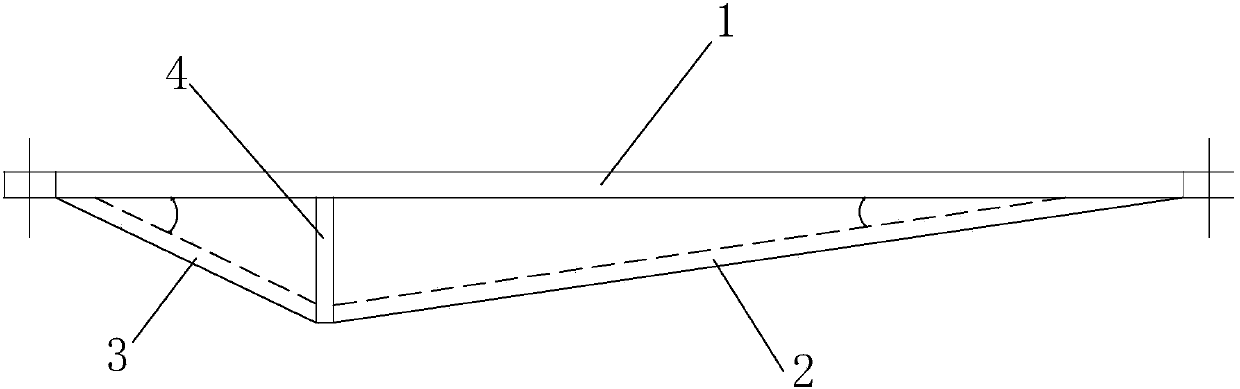

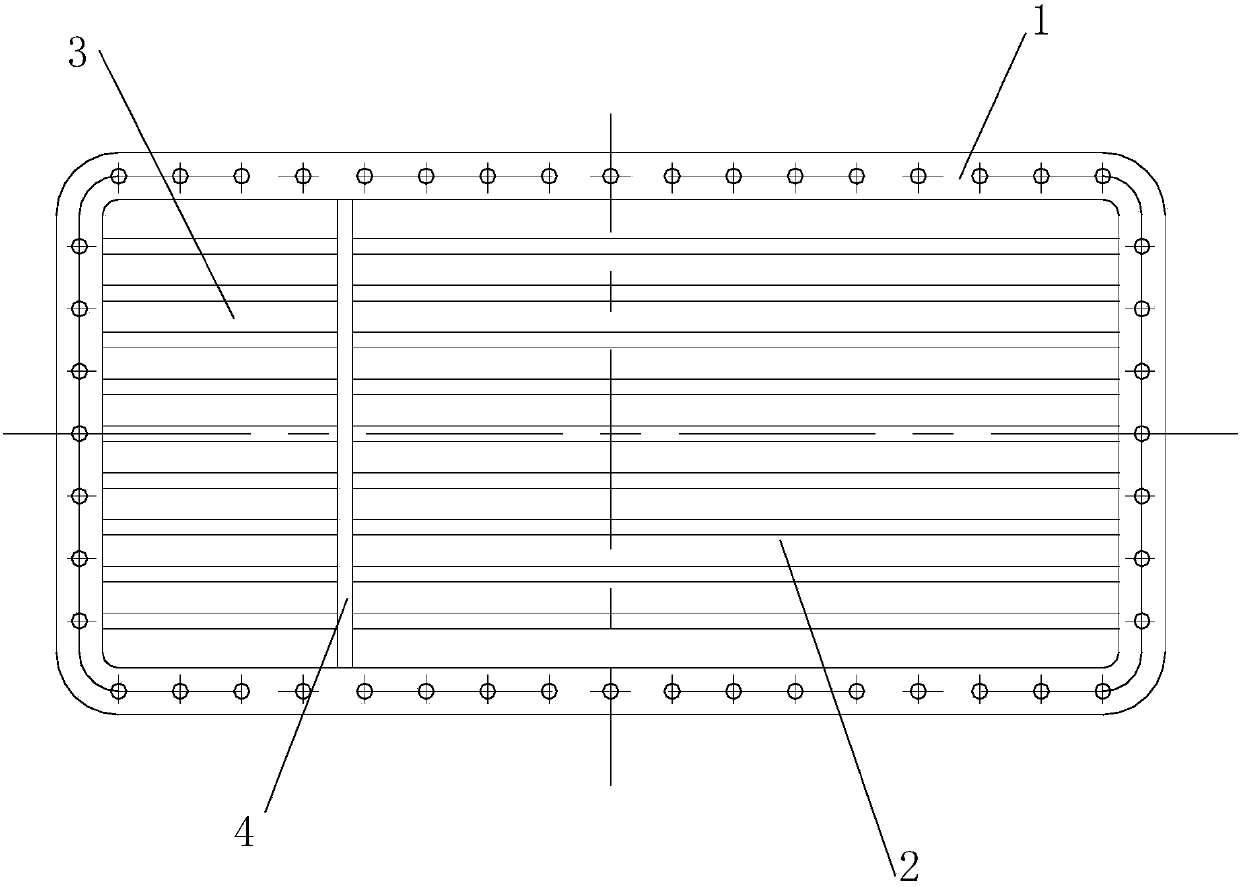

[0026] Such as Figure 1-2 As shown, the present embodiment provides a marine high-efficiency water intake device, which includes a frame 1 for connecting with the sea valve box, and also includes a front grille 2 and a rear grille 3 respectively connected to both ends of the frame 1. The frame 1, the front grid plate 2 and the rear grid plate 3 form a triangular space, a certain angle of forward inclination is formed between the front grid plate 2 and the frame 1, and a certain angle of back inclination is formed between the rear grid plate 3 and the frame 1, The connection between the front grid 2 and the rear grid 3 is also provided with a water blocking plate for pocketing water. The water blocking plate is located in the triangular space. This device can effectively improve the water inlet efficiency of the sea valve box, especially When the ship is sailing at high speed, whether it is in the forward or reverse condition, it can realize efficient water intake to meet the ...

Embodiment 2

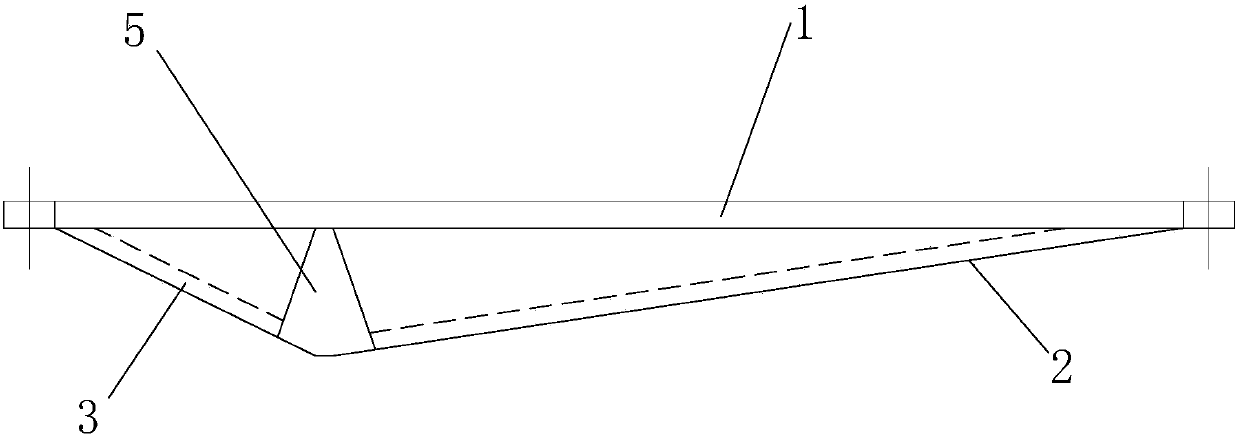

[0031] Such as Figure 3-4 As shown, the difference between this embodiment and Embodiment 1 is that the water blocking plate is a wedge-shaped plate 5, and one side of the small thickness of the wedge-shaped plate 5 is connected to the frame 1, no matter whether the ship is advancing or retreating, the The above-mentioned wedge-shaped plate 5 can play a good role in pocketing water, forming a positive pressure head near the front grid plate 2 or the rear grid plate 3 and the wedge-shaped plate 5, so as to promote seawater to enter the sea valve box more easily, and improve the water inlet device. water intake efficiency. Further, the wedge plate 5 has an inclined streamlined curved surface, which has less resistance to the navigation of the ship and is more practical.

Embodiment 3

[0033] Such as Figure 5-6 As shown, the difference between this embodiment and Embodiment 1 is that the water blocking plate is a movable straight plate 6, one end of the movable straight plate 6 is hinged with the junction of the front grid plate 2 and the rear grid plate 3, and the other end can be Free swing within a certain angle range. When the ship is moving forward, the movable straight plate 6 is in a backward tilting state, and when the ship is retreating, the movable straight plate 6 is in a forward tilting state, further, the frame 1 is provided with a limiter for limiting the swing range of the movable straight plate 6 Block 7. No matter the ship is in the process of advancing or retreating, the movable straight plate 6 can play a good role in pocketing water, and a positive pressure head is formed near the front grid plate 2 or rear grid plate 3 and the movable straight plate 6, so as to promote seawater to enter more easily In the sea valve box, the water inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com