Blast furnace carbon block crane and carbon block installation method

A lifting truck and lifting device technology, which is used in cranes, transportation and packaging, load hoisting components, etc., can solve the problems of construction stagnation, affecting construction progress, hidden dangers of blast furnace safety, etc., so as to avoid secondary damage and prolong use. longevity and the effect of ensuring stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

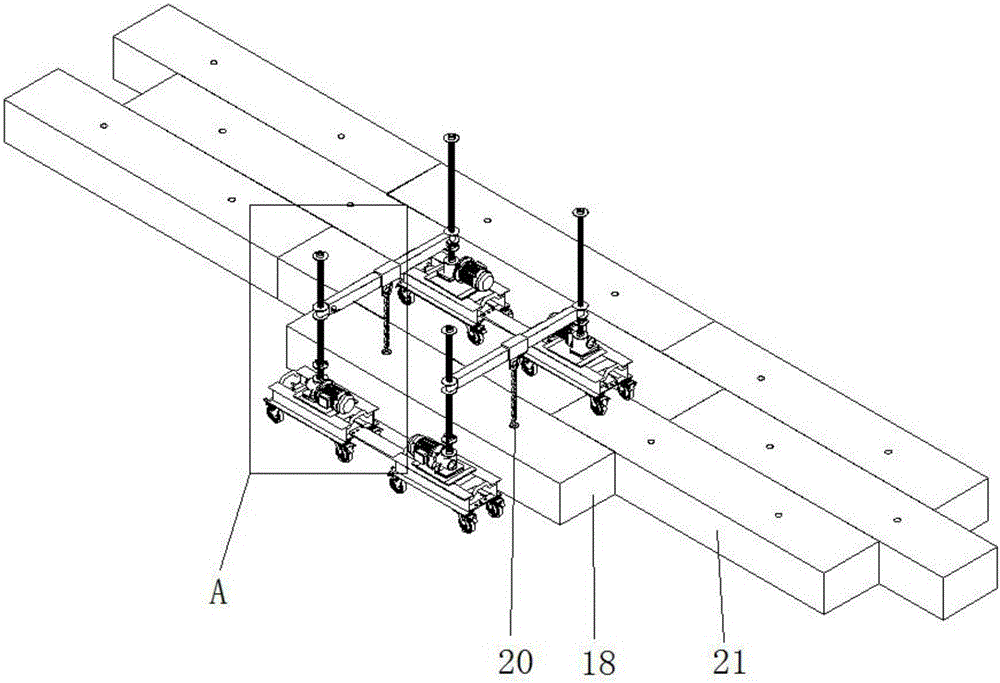

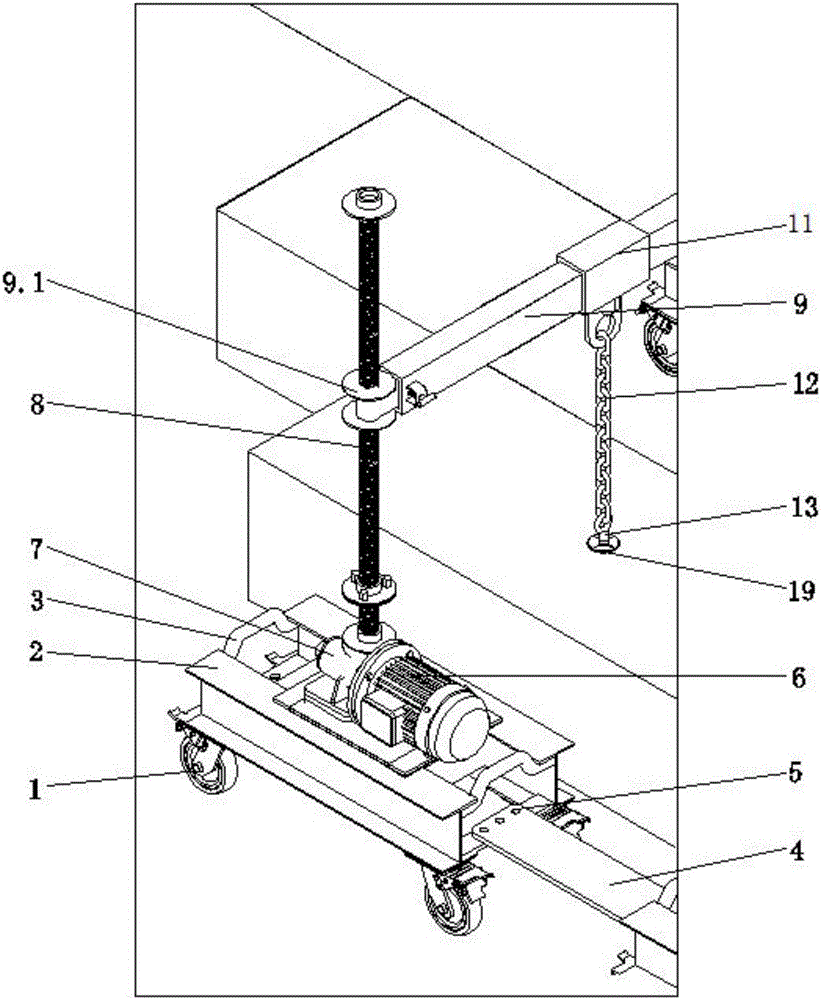

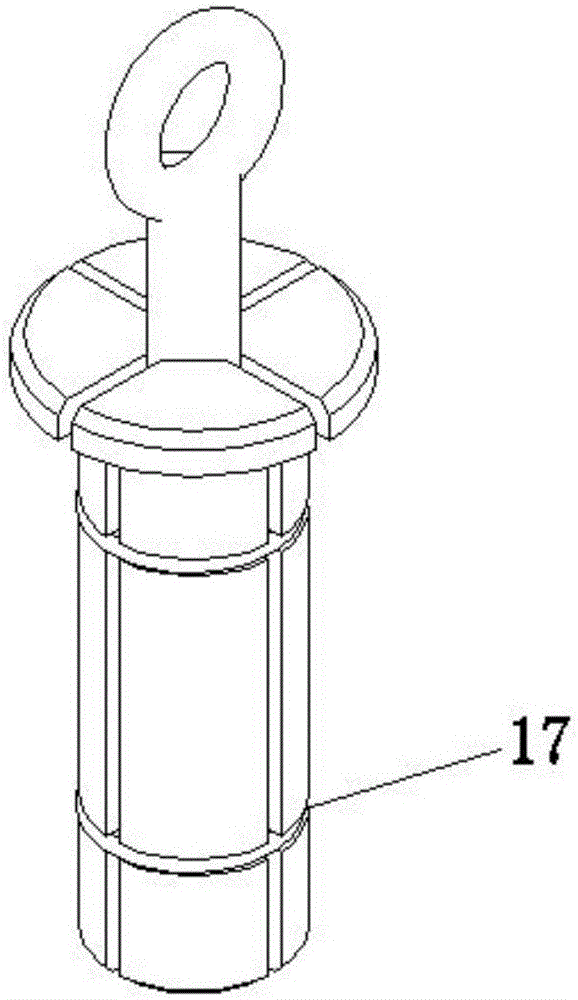

[0034] Such as figure 1 and figure 2 A blast furnace carbon block lifting vehicle shown includes two lifting devices located on both sides of the carbon block. The lifting device includes a base 2, a motor 6, a worm gear actuator 7 and a screw rod 8. The front end of the base 2 and Each rear end is equipped with a handle 3 (weldable, convenient for staff to move); the bottom of the four corners of the base 2 are respectively equipped with universal wheels 1 (weldable connection), and the upper part of the base 2 is fixedly installed with a motor 6 and a worm gear actuator 7 , the motor shaft of the motor 6 is connected to the input end of the worm gear actuator 7, and the output end of the worm gear actuator 7 is connected to the screw rod 8; a boom 9 is installed between the two lifting de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com