Embedded pile installation structure for overhead suspension beam

A technology for installing structures and hanging beams, which is applied to moving rail parts, roads, tracks, etc., can solve the problems of limited bearing capacity, poor toughness, and difficulty in adapting to large-span positions of foundation piles, and achieve the goal of improving bearing capacity and improving bearing capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

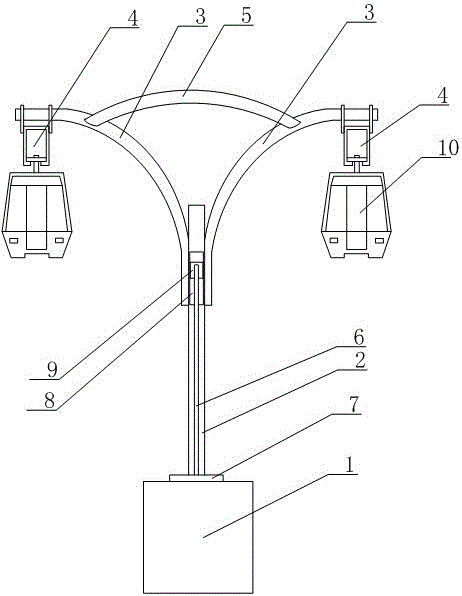

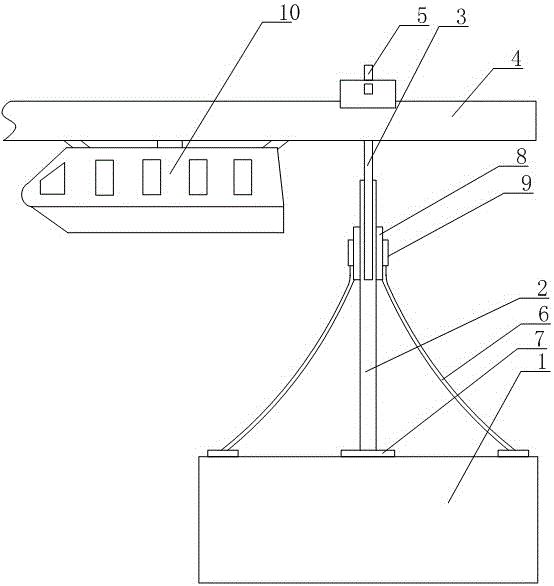

[0026] Such as Figures 1 to 2 As shown, the present invention is a pre-embedded pile installation structure for suspended beams in the air, including the main strut 2 installed on the foundation cap 1, the foundation cap 1 is used as the foundation of the entire foundation pile, and is formed by pouring reinforced concrete. Fasteners are pre-embedded during pouring, and the main strut 2 is fixed on the foundation cap 1 through the connecting piece 7. The main strut 2 is a steel structure, and cantilever 3 is set on both sides of it. The cantilever 3 arranged symmetrically makes the foundation pile The force is relatively uniform, the cantilever 3 is a downwardly curved arc structure, and the middle part of the two cantilever 3 is also provided with a tie arm 5, the two ends of the tie arm 5 are bent downward, and the middle part protrudes upward to form a curved structure. The end of the cantilever 3 is equipped with a track beam 4, and the sky train 10 runs in the track beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com