An Anti-Settlement Structure of High Embankment Filled Bridge Head

An anti-settlement and pavement structure technology, used in bridges, bridge parts, bridge construction, etc., can solve the problems of bridge head jumping, subgrade filling not reaching the compaction degree, subgrade filling loss and other problems, to overcome large dynamic stress. , Solve the effect of bridge jumping and smooth transition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

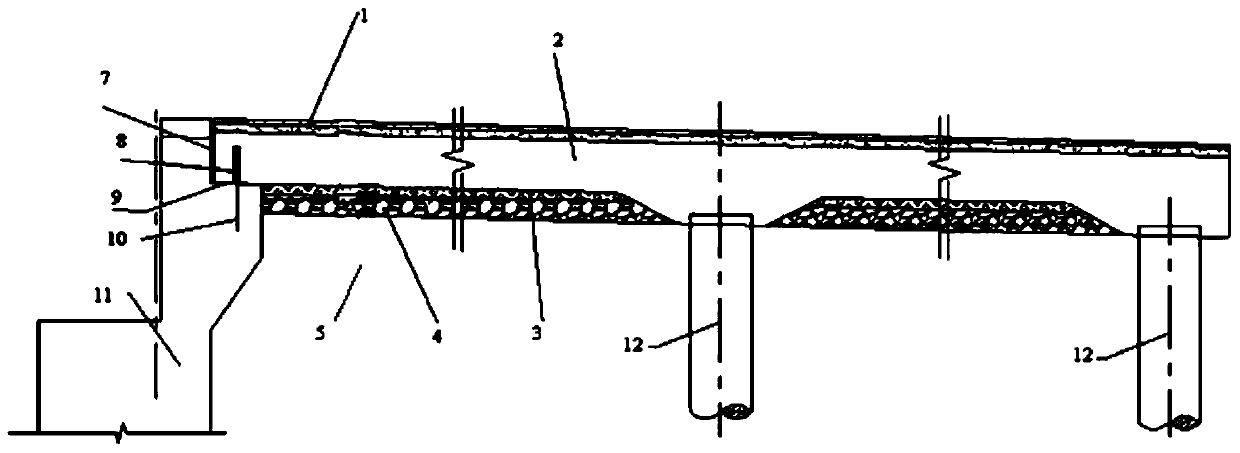

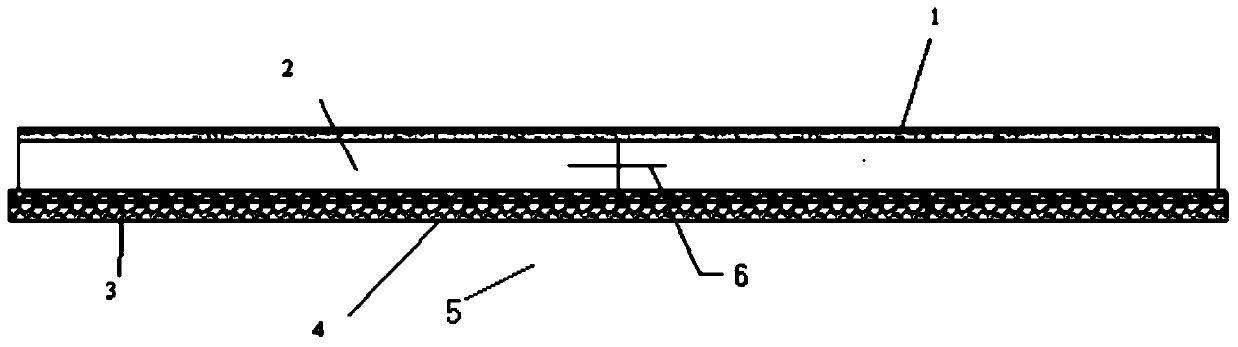

[0025] Such as Figure 1 to Figure 4 As shown, an anti-settlement structure of a bridge head filled with high embankment includes an abutment, a pile foundation structure 12, a pavement structure layer 1, a slab structure layer 2 and a road base layer 5.

[0026] The pavement structure layer 1 is designed according to road grades, usually coarse-grained asphalt+medium-grained asphalt+asphalt mastic macadam mixture, and can be designed as (from bottom to top) 6mm slurry seal layer+80mm coarse Granular asphalt concrete (AC-25C) + 60mm medium granular asphalt concrete (AC-20C) + 40mm asphalt mastic macadam mixture SMA-13 (SBS modified). The pavement structure layer 1 is laid on the slab structure layer 2,

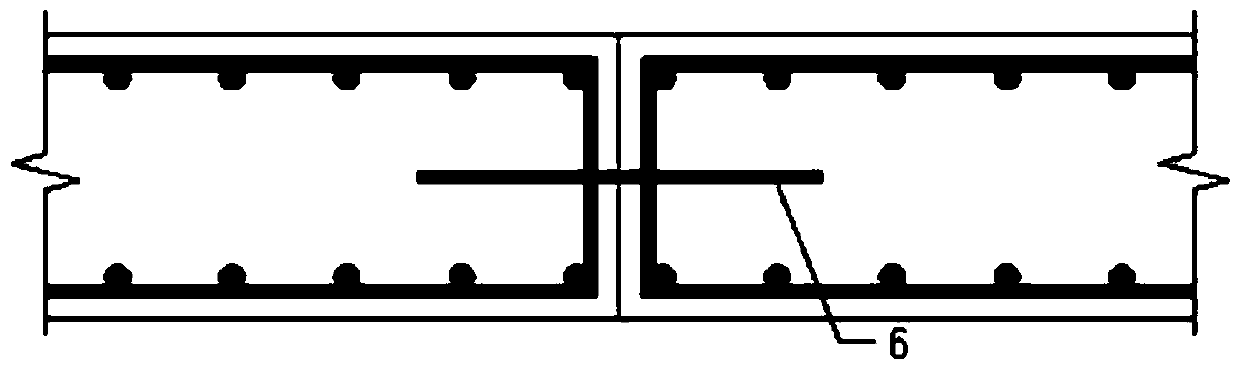

[0027] Described board structure layer 2 comprises board, is provided with longitudinal reinforcing bar 14 and transverse steel bar 15 in this board, to strengthen the intensity of board, pile foundation structure 12 is arranged at intervals below the board, and is position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com