Narrow-deep type prefabricated drainage gutter

A technology of narrow and deep side ditches, which is applied in the direction of drainage structures, side ditches/curbstones, waterway systems, etc., and can solve the problems of large grading, large land occupation, many land use restrictions, and unnecessary land occupation. , to achieve the effect of reducing the occupied area, good integrity and safety, and saving the amount of flushing water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

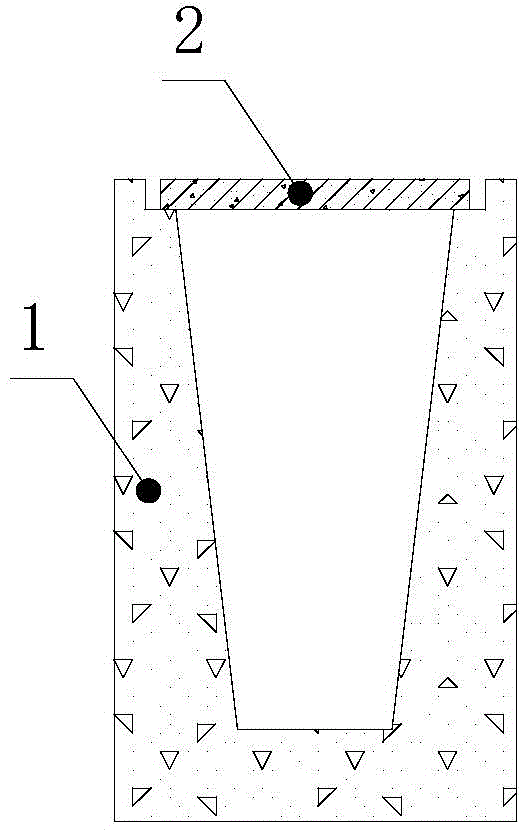

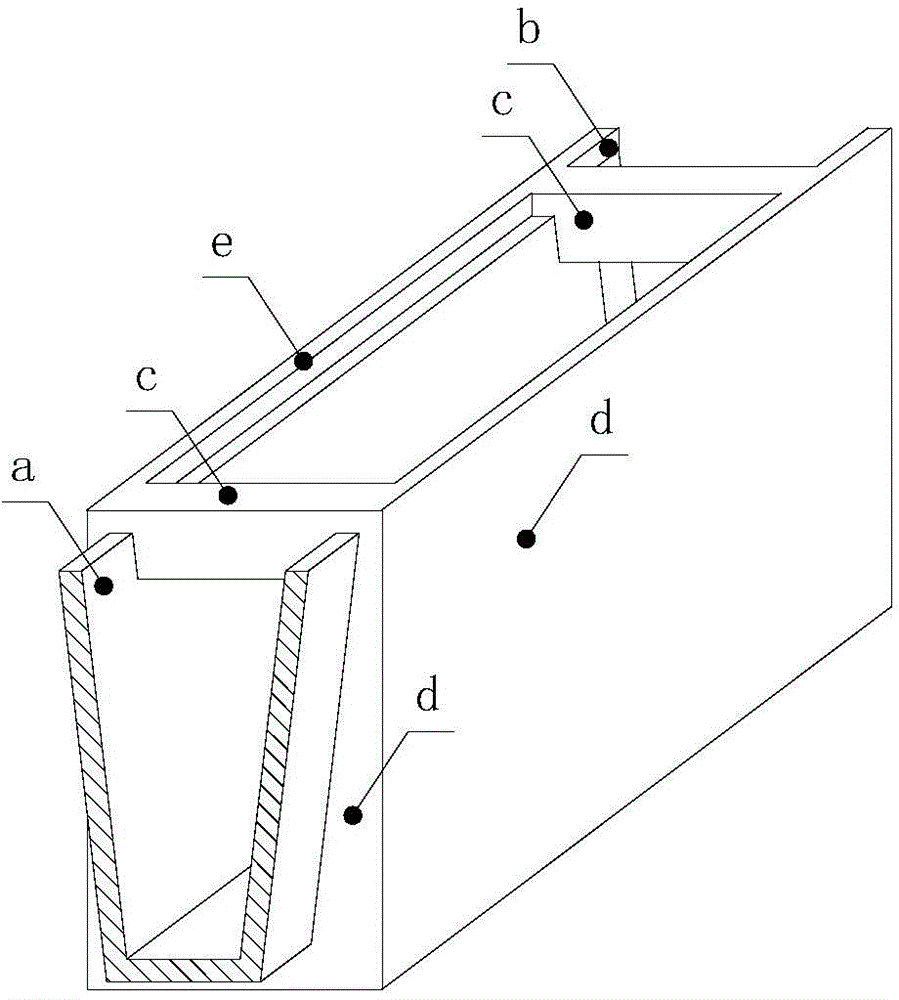

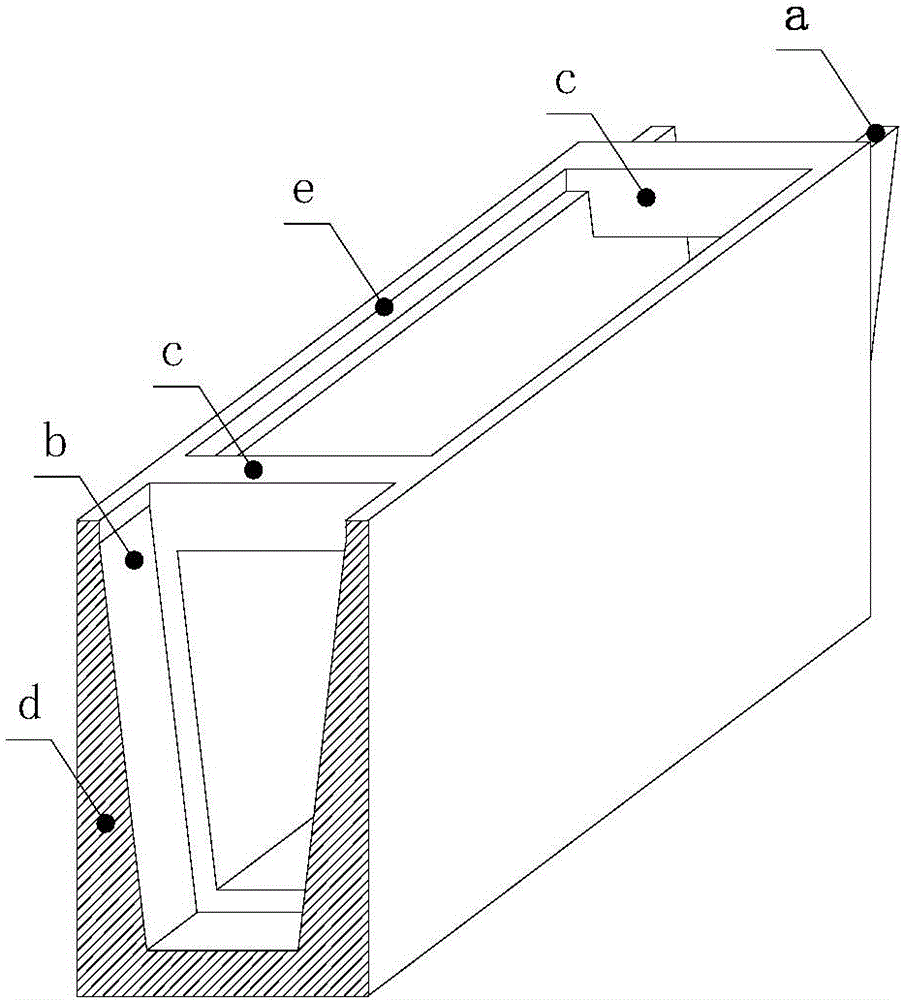

[0028] Specific examples: such as Figure 1-5 As shown, the main body 1 of the drainage side ditch has an overall size of 2000mm×650mm×1050mm, the cross-section of water is 0.29㎡, the size of the cover plate 2 is 740mm×640mm×50mm; 150mm×150mm, the detailed construction steps are as follows: (1) Prefabricate the side ditch according to the design length of the side ditch; (2) Excavate the pit body and make the foundation; (3) Install the main body 1, and paint waterproof adhesive material on the inside of the groove b , Lap tenon a and groove b sequentially; (4) install cover plate 2; (5) backfill soil on both sides of side ditch main body 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com