A bearing sealing ring

A bearing sealing and steel ring technology, applied in the field of bearing sealing rings, can solve the problems of insufficient strength, easy deformation and failure, and easy falling off of the rubber ring and steel ring skeleton, so as to achieve the effects of not easily falling off, increasing strength, and preventing falling off deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

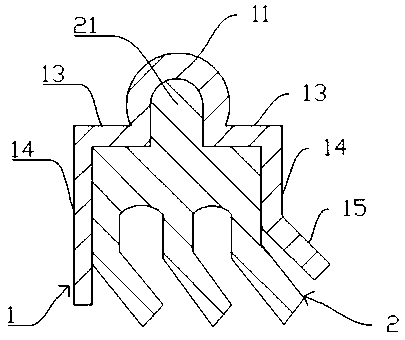

[0018] Embodiment 1: as figure 1 , figure 2 with image 3 As shown, a bearing sealing ring is composed of an outer steel ring frame 1 and an inner rubber ring 2. The rubber ring 2 and the steel ring frame 1 are preferably glued together to reduce mutual displacement between the two.

[0019] The top of the steel ring frame 1 is provided with a top beam 11 that is convex on the outside in an arc shape, and a groove is formed inside the top beam.

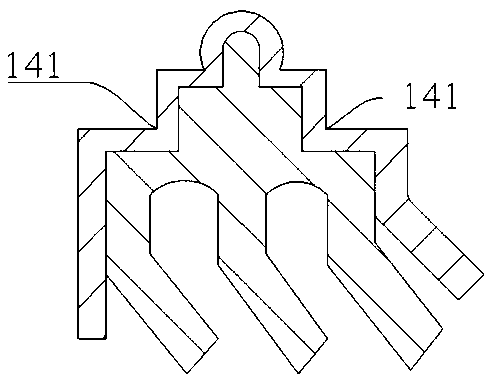

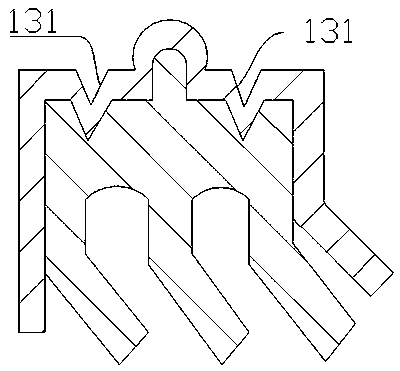

[0020] Both ends of the arc-shaped top beam are respectively connected with upper beams 13, and the upper beams 13 are respectively connected with side vertical beams 14, wherein the bottom of the right side vertical beam is provided with an inclined beam 15 inclined outward.

[0021] When the top beam 11 is installed, it will cooperate with the sealing groove of the outer ring of the bearing. Usually, the sealing groove of the outer ring of the bearing is also arranged in an arc shape, and the arc diameter of the sealing groove i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com