A Modification Method for the Archimedes Surface Wedge of the Bracing Clutch

A technology of Archimedes curve and clutch, which is applied in the field of modifying the archimedes surface wedge of the sprag clutch, which can solve the problems of reducing the load capacity of the clutch and achieve the effect of increasing the load capacity and improving the wedging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below through specific examples.

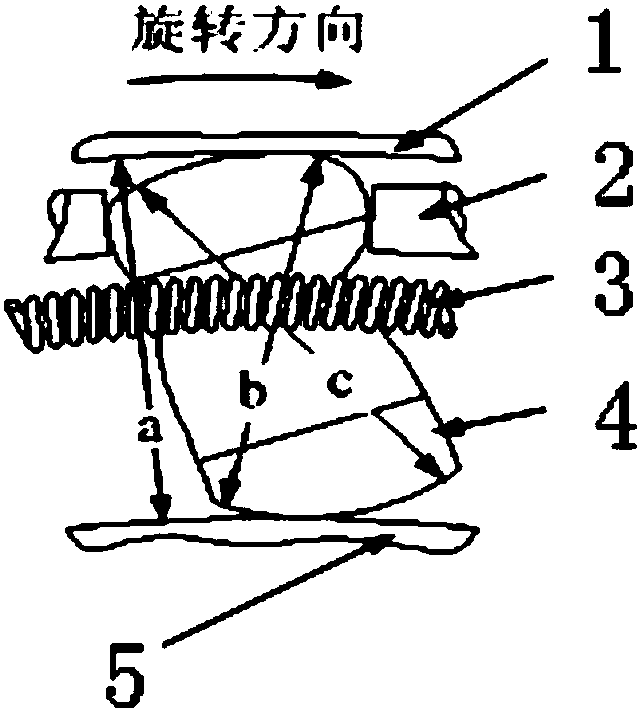

[0047] see figure 1 , The sprag type overrunning clutch is composed of sprag 4, inner ring 5, outer ring 1, cage 2 and spring 3.

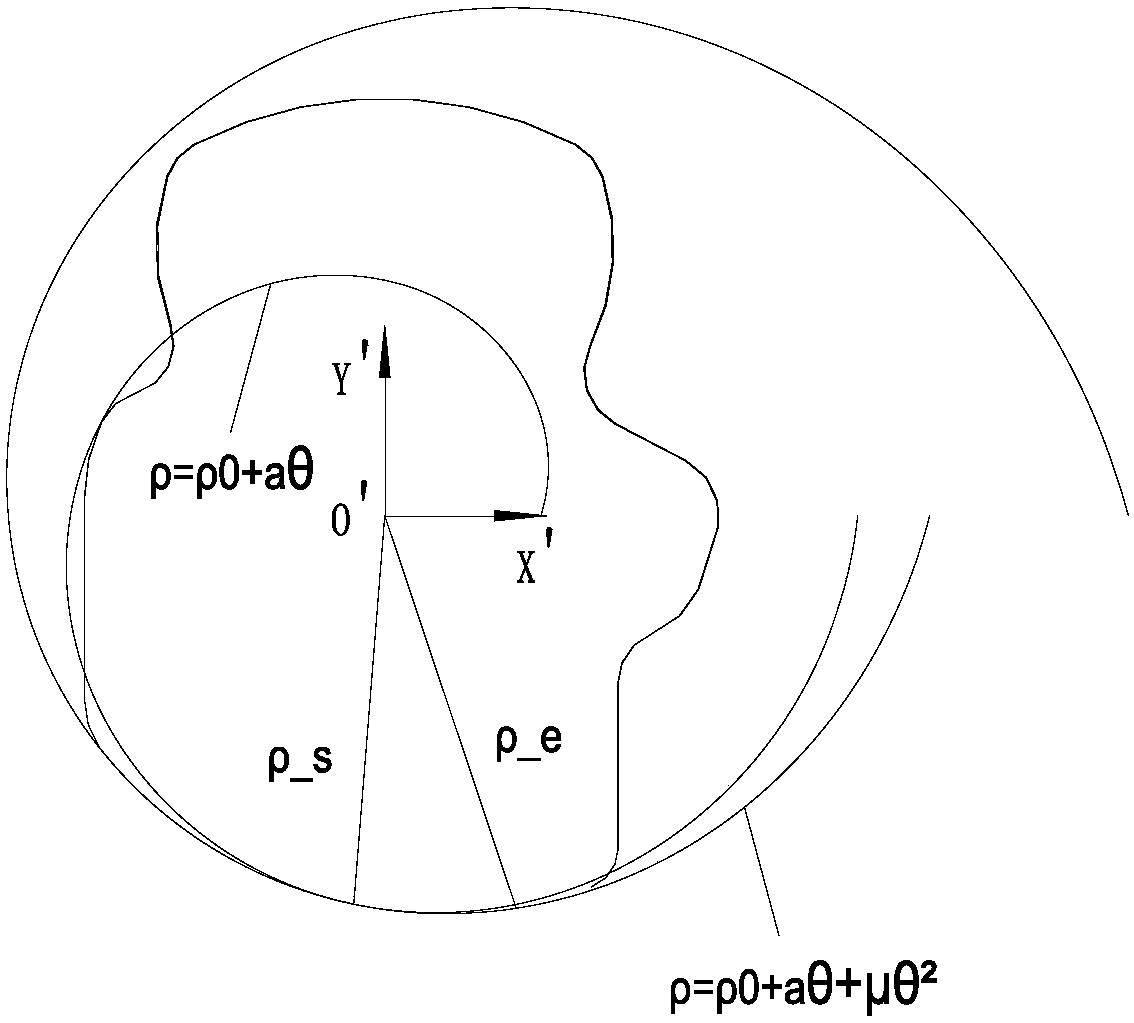

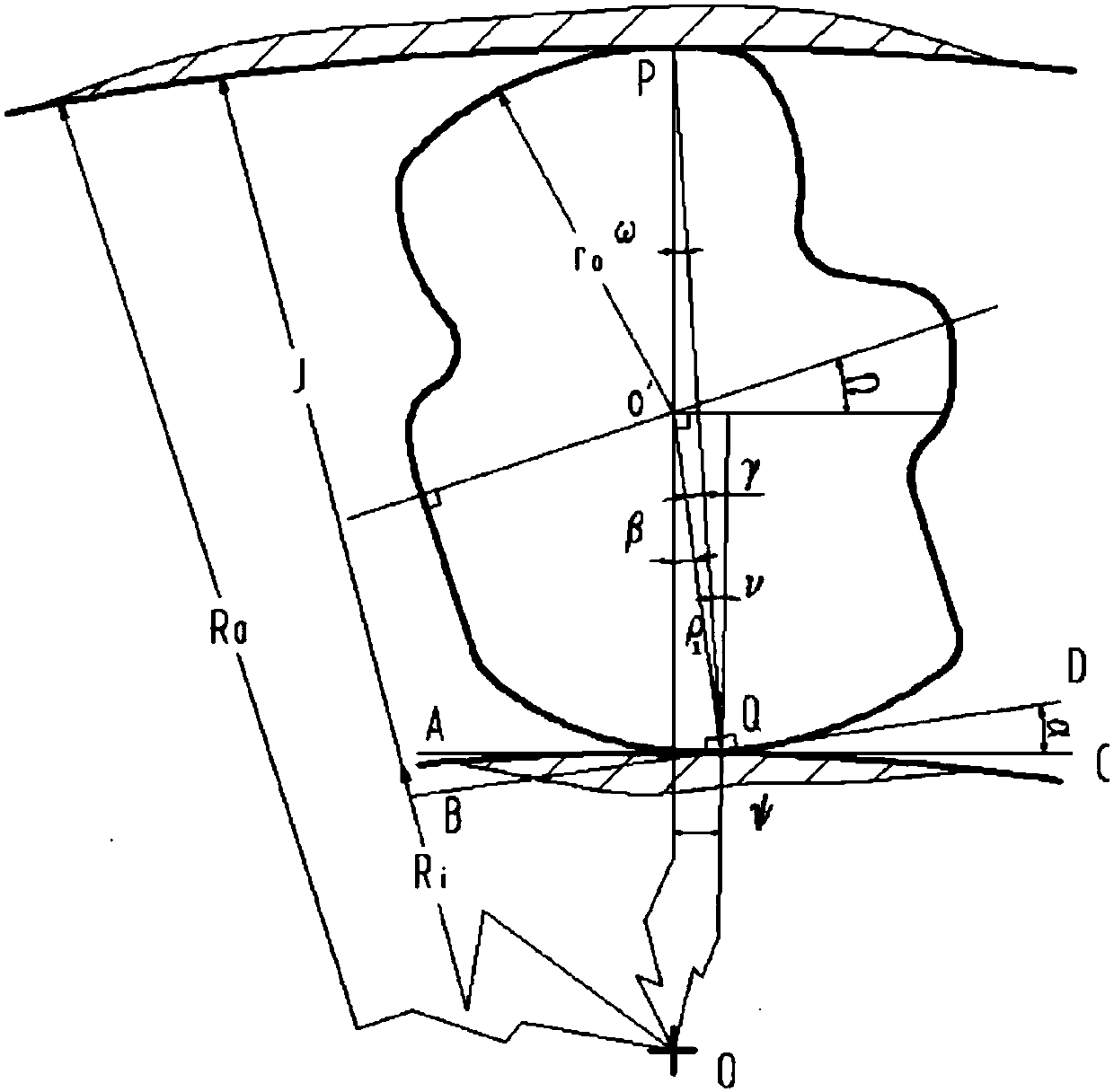

[0048] see figure 2 and image 3 , the modification method of the archimedes curved surface wedge of the sprag clutch provided by the present invention, the cam modification curve under the wedge is established as: ρ=ρ0+aθ+μθ 2 , where ρ0 is the initial polar diameter, θ is the polar angle, a is the coefficient, and μ is the modification coefficient.

[0049] Determining the modification curve includes: obtaining the working torque according to the power and speed of the clutch; according to the working torque and referring to the three-arc surface clutch to obtain the number of sprags n and the radius R of the inner ring i , outer ring radius R o , wedge effective length and other structural parameters; according to the structural size parameters of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com