A bottom vibration isolator with independent adjustable vertical and horizontal damping

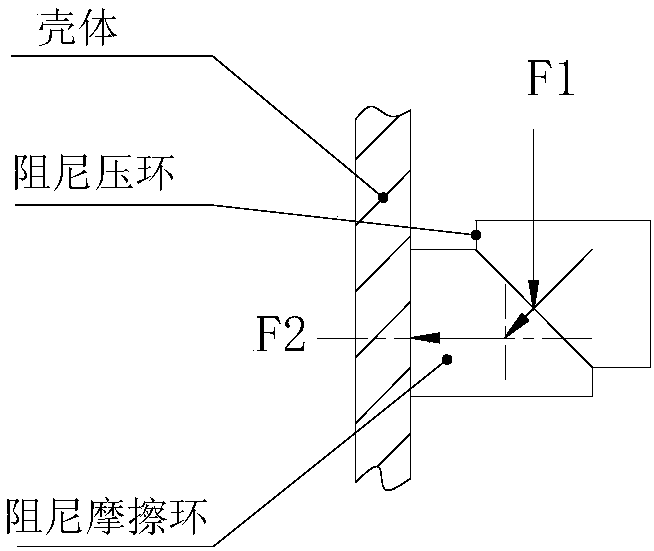

A horizontal and adjustable technology, used in shock absorbers, friction shock absorbers, shock absorbers, etc., can solve the problems of easy slippage of steps, hard damage to the inner wall, and the upper damping plate is not positioned, so as to achieve less wear and tear. , Improve the service life and improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

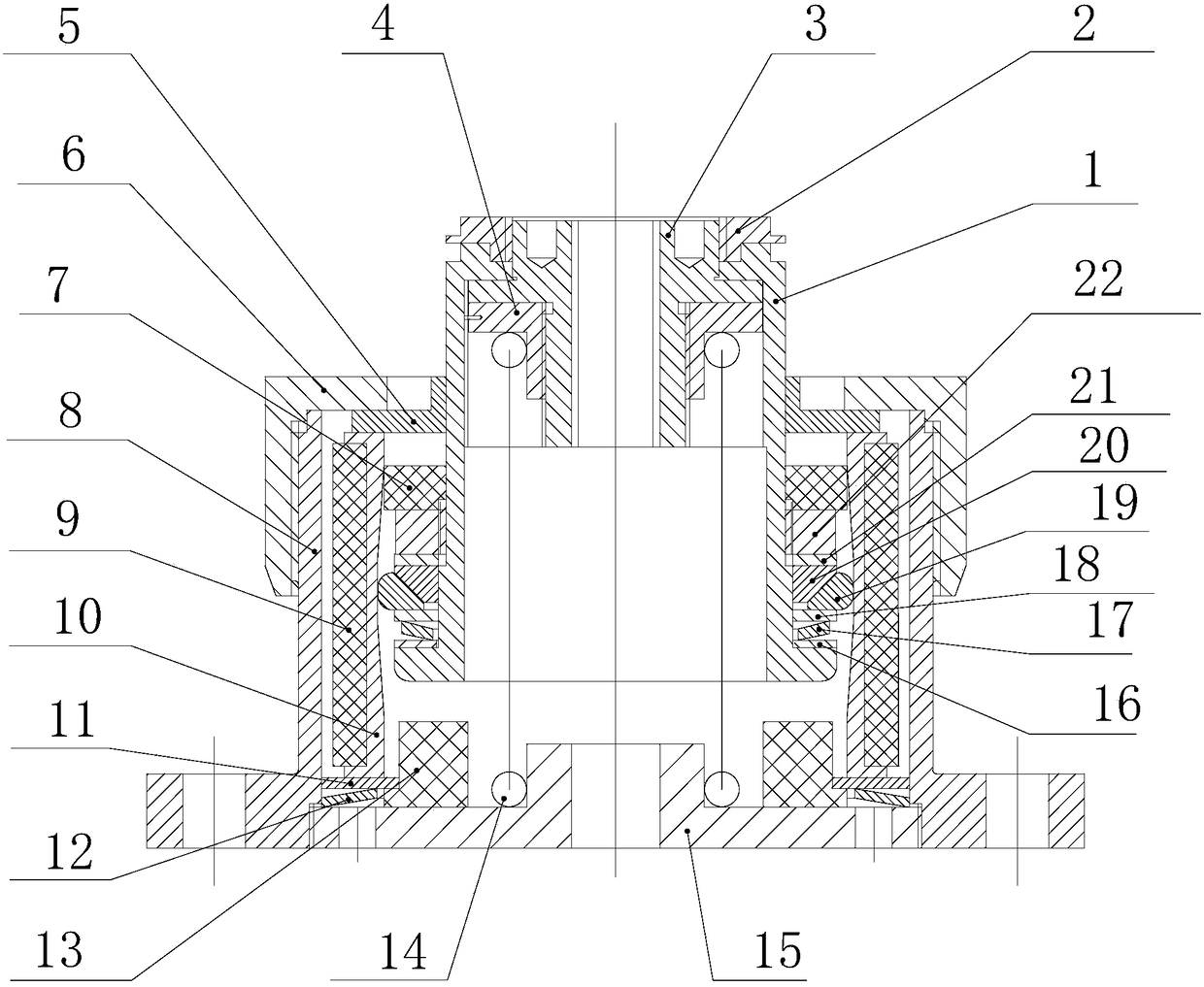

[0042] A bottom vibration isolator with independent adjustable vertical and horizontal damping. The base, the upper cover and the bearing cylinder are made of stainless steel or hard aluminum alloy. Structure like figure 2 As shown, the base is composed of a cylindrical base body 8, a bottom plate 15 covering the bottom of the base body, and an upper cover 6 covering the mouth of the base body. The bottom plate 15 is provided with a mounting boss that sleeves the main spring 14 , There is an opening at the top of the upper cover 6 for the carrying cylinder 1 to extend, the inner side wall of the upper cover 6 abuts against the body of the upper slide 5; the lower part of the damping cylinder 10 abuts the bottom plate through the lower plate 11 and the lower disc spring 12 15. The upper part of the damping cylinder 10 abuts against the inner side surface of the upper cover 6 through the upper sliding piece 5, the bottom plate 15 under the orthographic projection of the mounting ...

Embodiment 2

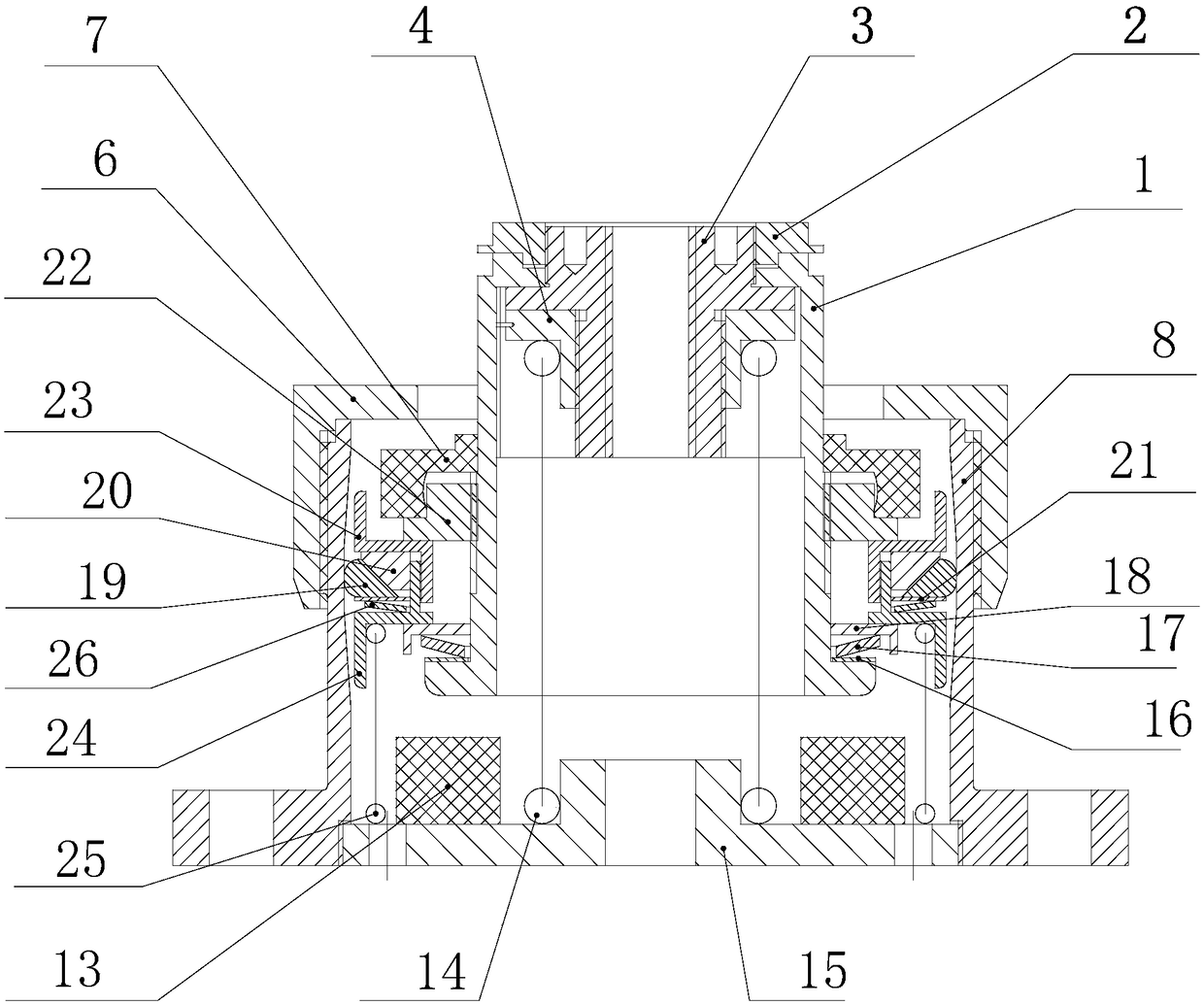

[0045] A bottom vibration isolator with independent adjustable vertical and horizontal damping. The base, the upper cover and the bearing cylinder are made of stainless steel or hard aluminum alloy. Structure like image 3 As shown, the base is composed of a cylindrical base body 8, a bottom plate 15 covering the bottom of the base body, and an upper cover 6 covering the mouth of the base body. The bottom plate 15 is provided with a mounting boss that sleeves the main spring 14 , There is an opening on the top of the upper cover 6 for the carrying cylinder 1 to extend; the bottom plate 15 under the orthographic projection of the mounting step of the carrying cylinder 1 is erected with a lower impact pad 13, and the damping lock nut 22 is on the side corresponding to the upper cover The sleeve has an upper bumper 7.

[0046] The lower end of the bearing cylinder 1 forms a convex baffle ring, and the bearing cylinder at the upper end of the baffle ring is sequentially sleeved with ...

Embodiment 3

[0048] A bottom vibration isolator with independent adjustable vertical and horizontal damping. The base, the upper cover and the bearing cylinder are made of stainless steel or hard aluminum alloy. Structure like Figure 4 As shown, the base is composed of a cylindrical base body 8, a bottom plate 15 covering the bottom of the base body, and an upper cover 6 covering the mouth of the base body. The bottom plate 15 is provided with a mounting boss that sleeves the main spring 14 , There is an opening on the top of the upper cover 6 for the carrying cylinder 1 to extend; the bottom plate 15 under the orthographic projection of the mounting step of the carrying cylinder 1 is erected with a lower impact pad 13, and the damping lock nut 22 is on the side corresponding to the upper cover The sleeve has an upper bumper 7.

[0049] The lower end of the bearing cylinder 1 forms a convex baffle ring, and the bearing cylinder at the upper end of the baffle ring is sequentially sleeved wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com