An anti-vibration and impact-resistant back vibration isolator

A shock-resistant and anti-vibration technology, used in shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve the problems of easy damage to the buffer pad, poor spring buffer effect, and deformation of the external adjustment screw sleeve. The effect of good buffering and reset effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

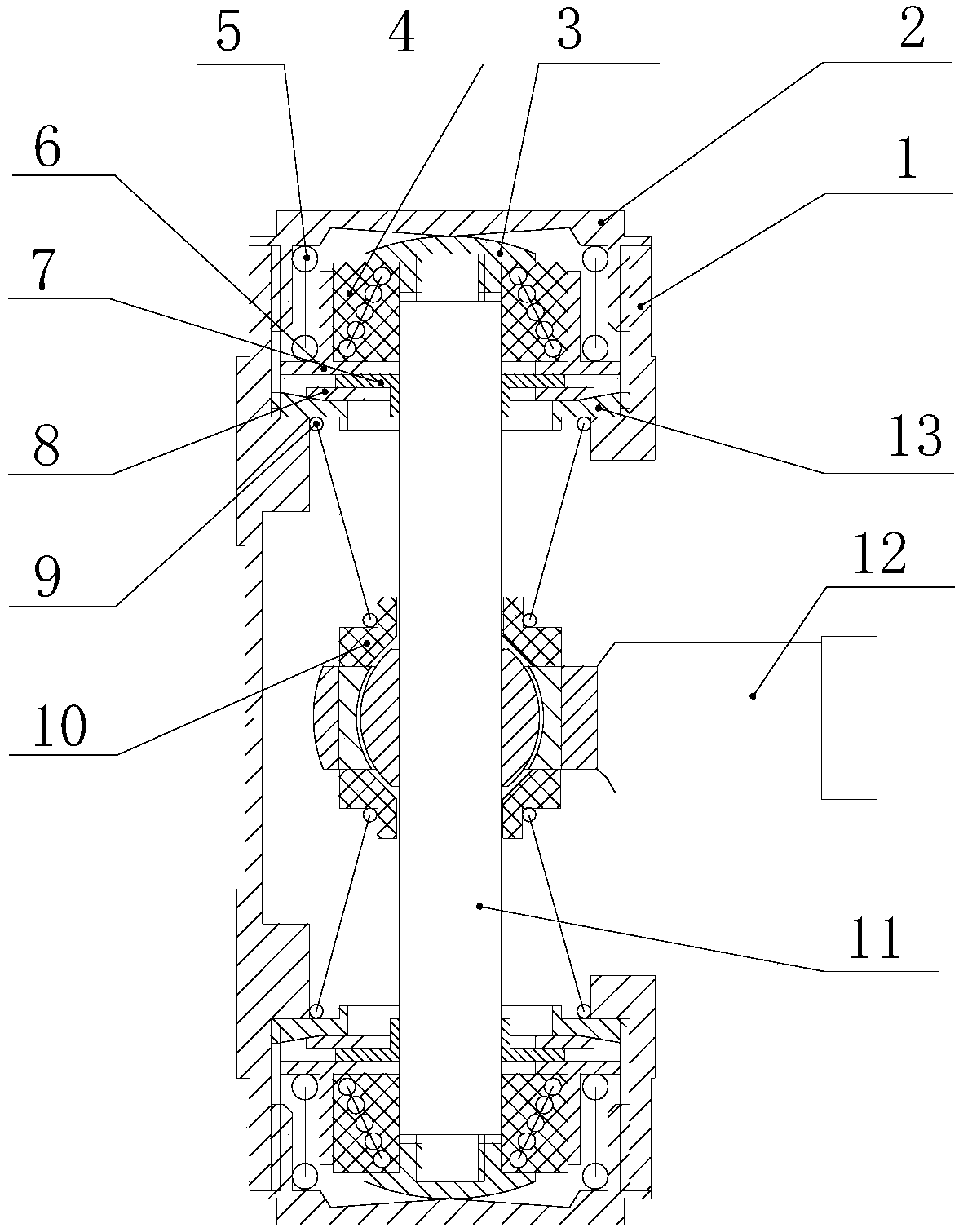

[0039] An anti-vibration and impact-resistant back vibration isolator, the base, upper cover and bearing cylinder are made of stainless steel or hard aluminum alloy. Such as figure 1 As shown, the shell 1 is provided with a strip-shaped hollow cavity, and the central axis 11 is placed in it along the length direction of the hollow cavity. A set of buffer adjustment devices are respectively accommodated between the two ends of the central axis 11 and the corresponding inner walls of the hollow cavity. The middle part of the central shaft 11 is connected with a joint bearing 12, and the joint bearing 12 has a connection end connected with the shock absorber; the central shaft on both sides of the joint bearing is respectively covered with an outer cone-shaped support spring 9, and one end of the support spring 9 is against Connected to the open ring 13 , the other end of the support spring 9 abuts against the joint bearing 12 through the spring seat 10 .

[0040] The buffer adj...

Embodiment 2

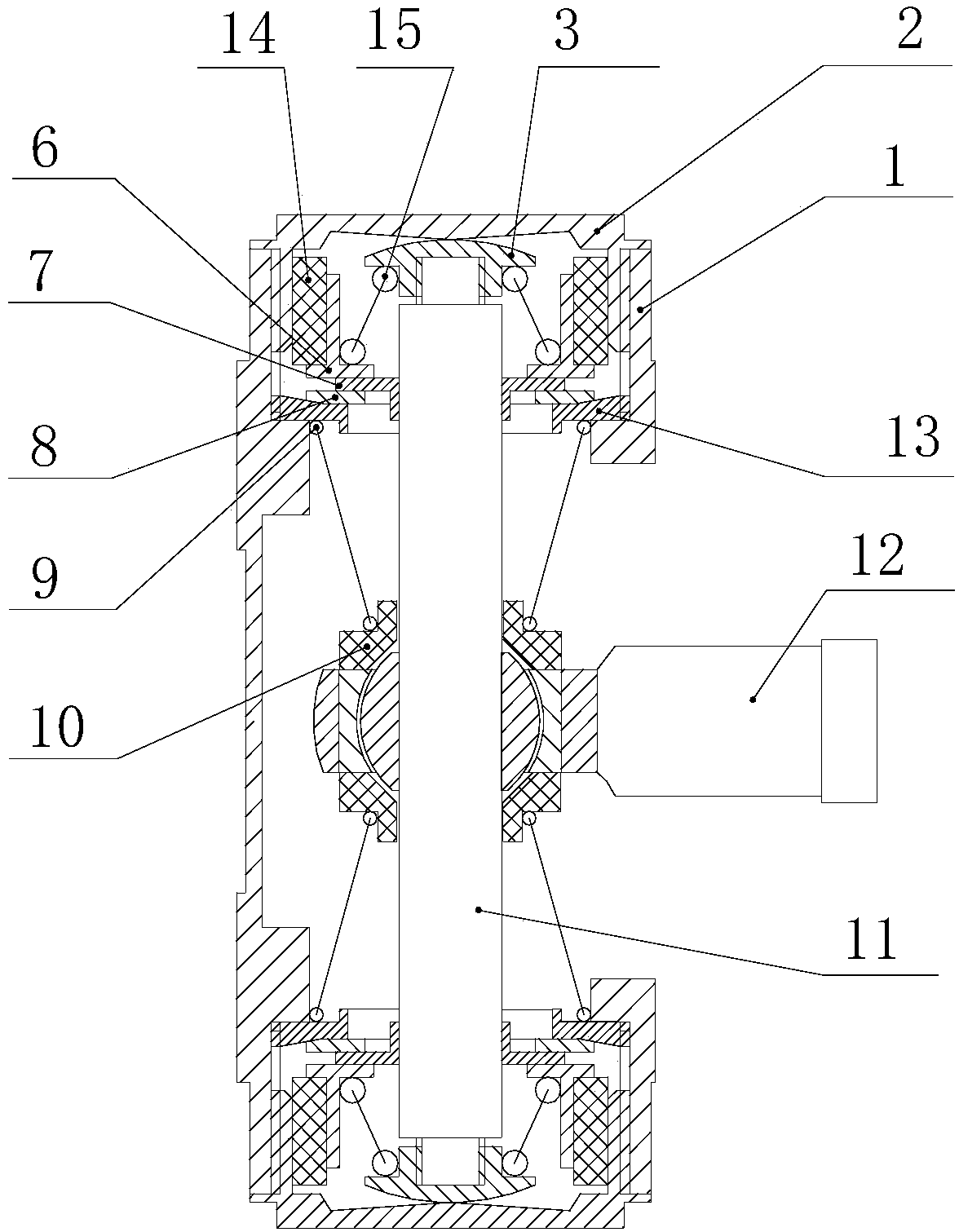

[0043] An anti-vibration and impact-resistant back vibration isolator, the base, upper cover and bearing cylinder are made of stainless steel or hard aluminum alloy. Such as figure 2 As shown, the shell 1 is provided with a strip-shaped hollow cavity, and the central axis 11 is placed in it along the length direction of the hollow cavity. A set of buffer adjustment devices are respectively accommodated between the two ends of the central axis 11 and the corresponding inner walls of the hollow cavity. The middle part of the central shaft 11 is connected with a joint bearing 12, and the joint bearing 12 has a connection end connected with the shock absorber; the central shaft on both sides of the joint bearing is respectively covered with an outer cone-shaped support spring 9, and one end of the support spring 9 is against Connected to the open ring 13 , the other end of the support spring 9 abuts against the joint bearing 12 through the spring seat 10 . The buffer adjustment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com