Steel bottle heating safety device

A safety device and technology of steel cylinders, which are applied in the method of container discharge, container filling method, gas/liquid distribution and storage, etc., can solve the problems of increased pressure of steel cylinders, safety accidents, explosions, etc., so as to ensure safe use and prevent safety effect of accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

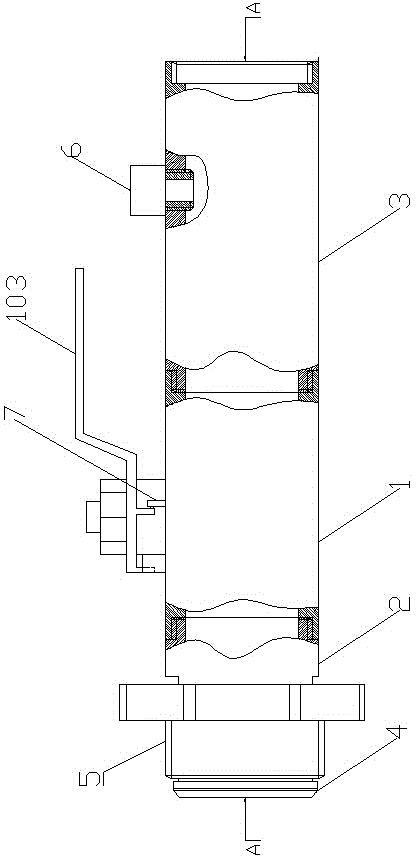

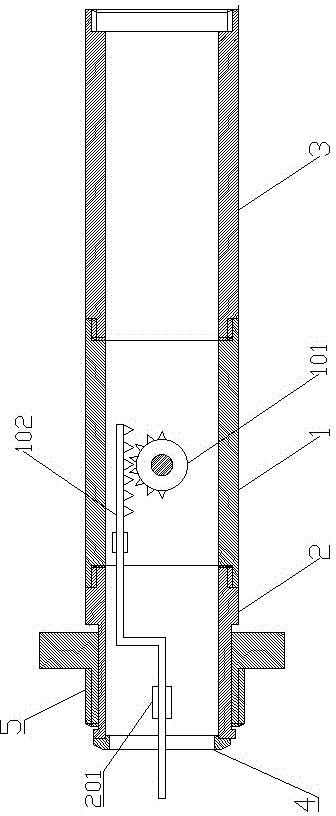

[0010] As shown in the figure, the steel cylinder heating safety device of the present invention includes a ball valve 1, the two ports of the ball valve 1 are respectively connected to the pipe head 2 and the pipe head 2 3, and the outer port of the pipe head 2 is installed with a sealing rubber pad 4, The connecting wheel 5 for connecting the steel cylinder is set on the pipe head 2, and the outer port of the pipe head 2 3 is provided with an internal thread; the valve core 101 side of the ball valve 1 is gear-shaped, and is connected to There is a rack 102, and the other end of the rack 102 is led out from the outer port of the pipe head 12, and a limit groove 201 is provided on the inner wall of the pipe head 2 corresponding to the position of the rack 102, and the rack 102 is located in the limit groove 201; a pressure switch 6 is provided on the pipe head 2 3, and the detection end of the pressure switch 6 is located in the pipe head 2 3; a micro-motion is provided on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com