Circulating fluidized bed combustion method for adjusting superheated steam temperature

A technology of circulating fluidized bed and superheated steam, which is applied in the control of superheated temperature, fluidized bed combustion equipment, combustion method, etc. It can solve the problems of affecting boiler efficiency, large baffle plate volume, narrow effective opening range, etc., and achieve The effect of good adjustment performance and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

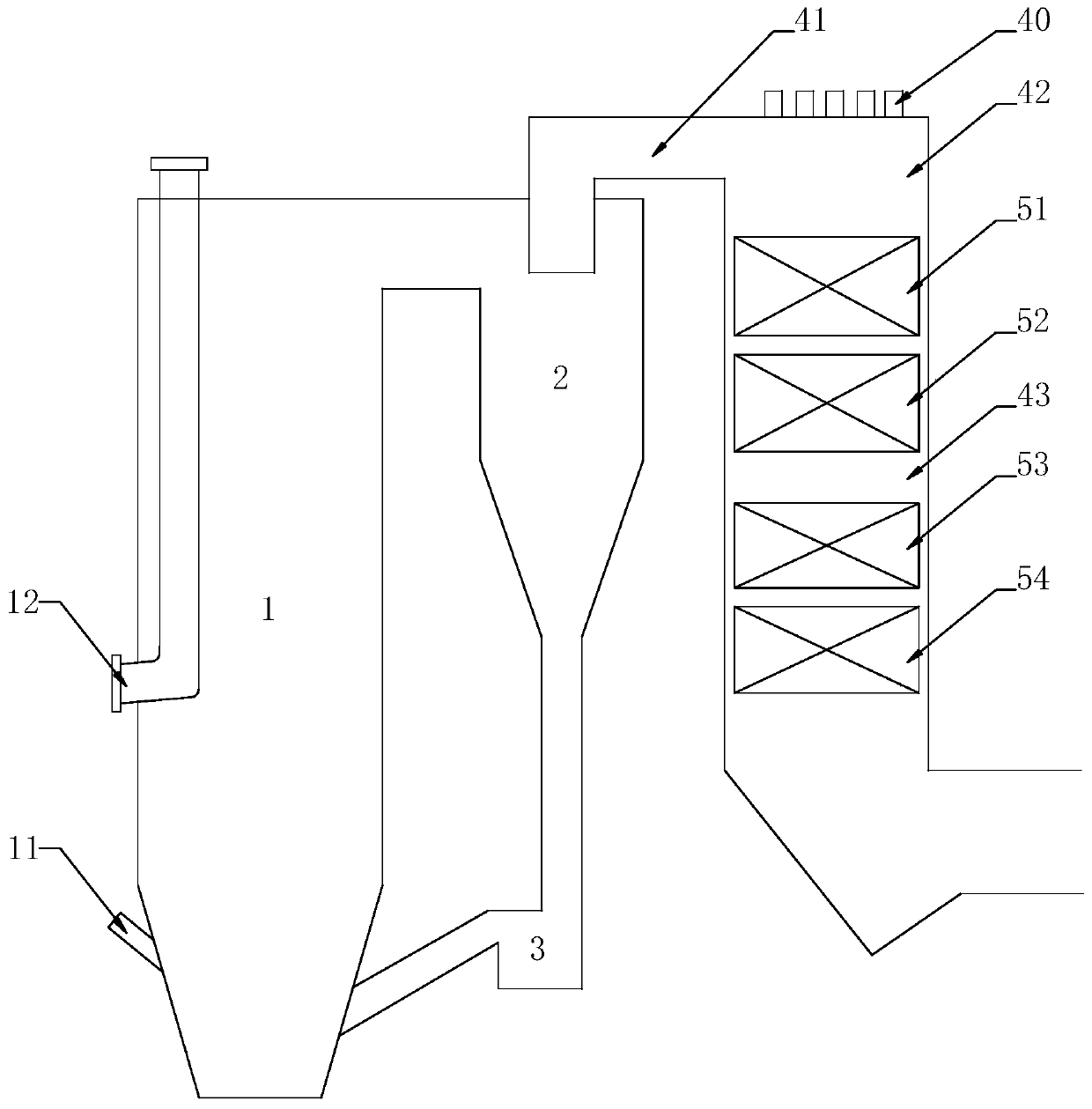

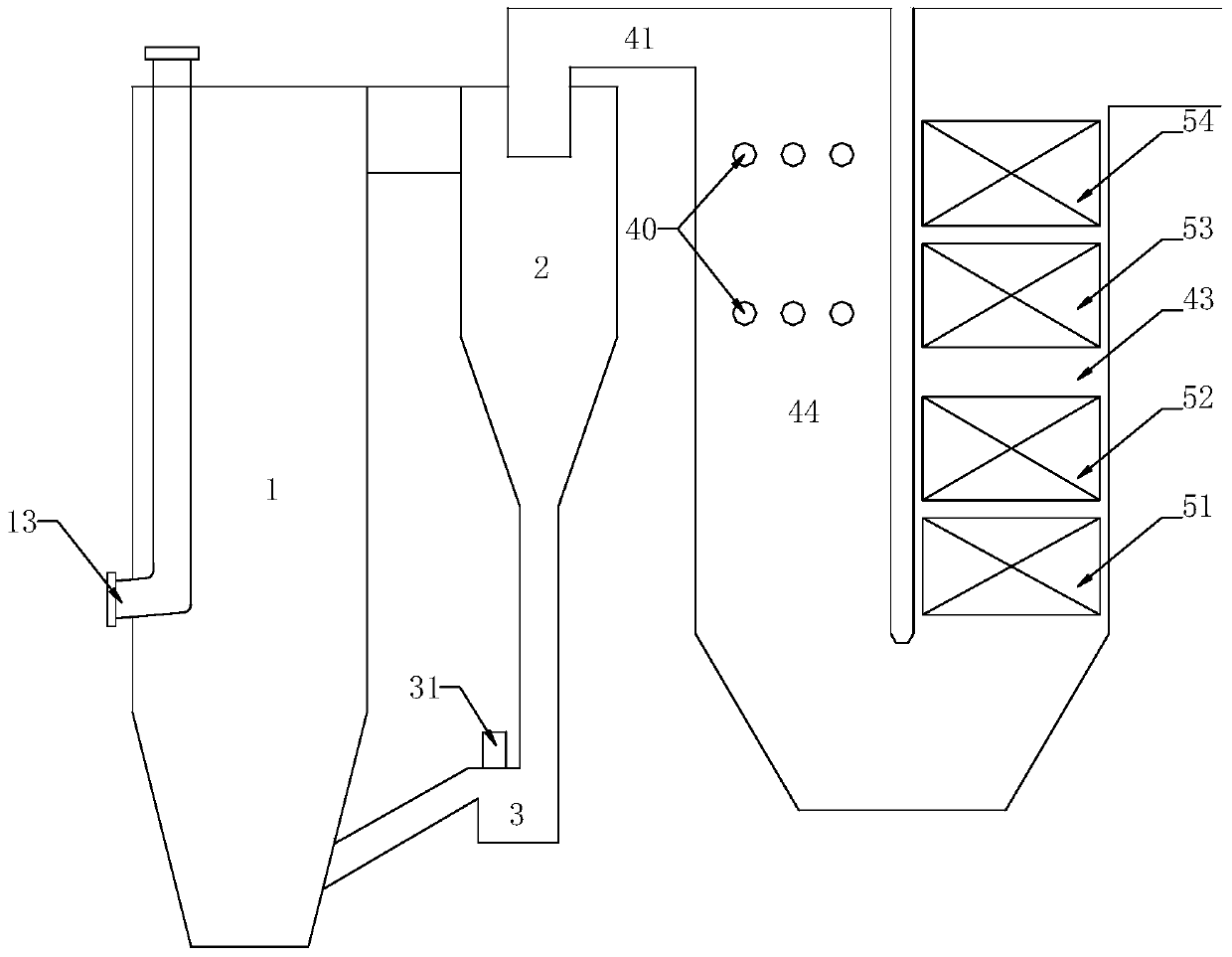

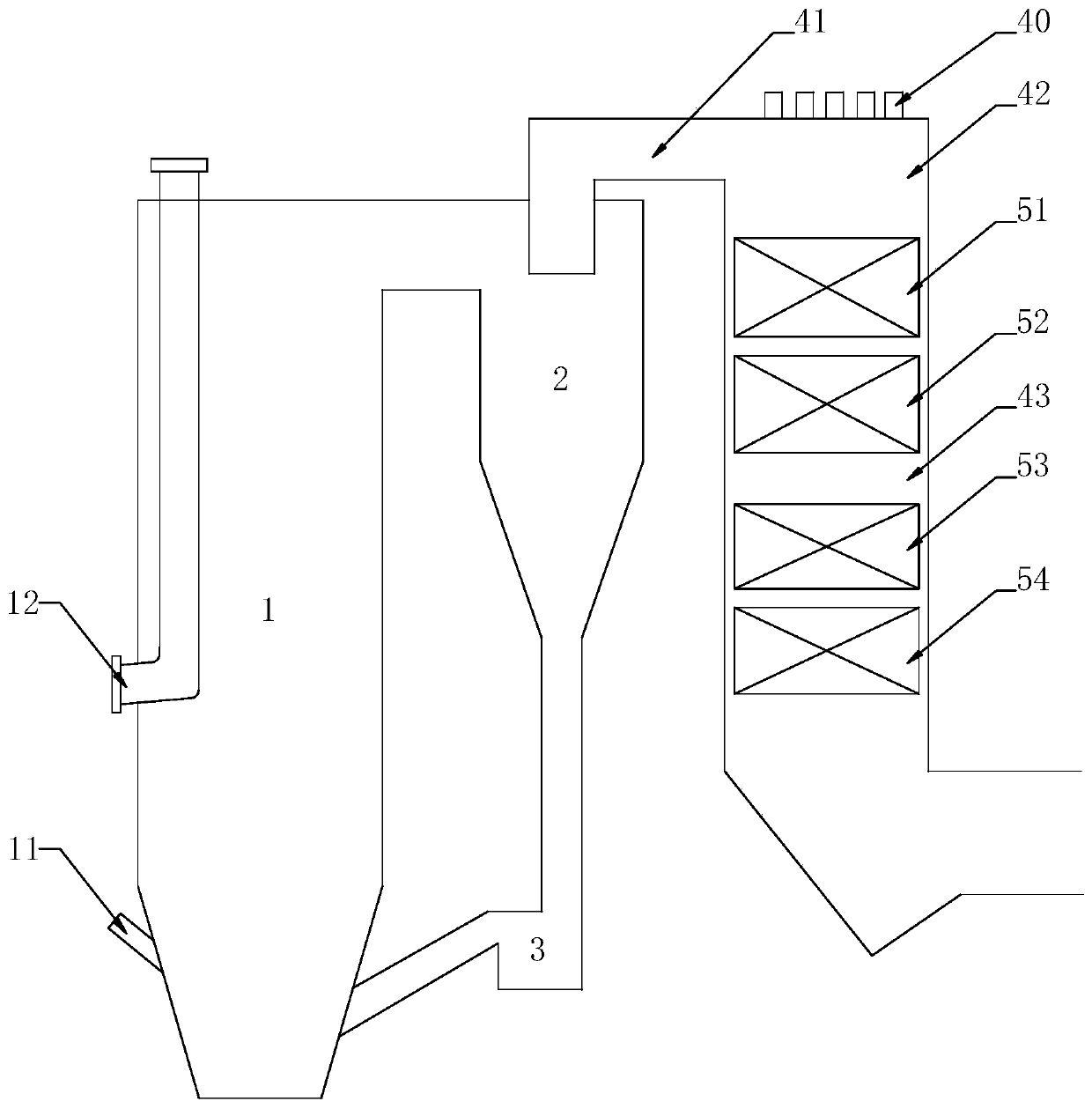

[0018] Exemplary embodiments of the present invention are described in detail below, examples of which are illustrated in the accompanying drawings, wherein the same or similar reference numerals designate the same or similar elements. The embodiments described below with reference to the figures are exemplary and are intended to explain the present invention, and should not be construed as limiting the present invention.

[0019] A conventional circulating fluidized bed boiler mainly includes a furnace, a gas-solid separator, a feeder, and a tail flue. Usually, the excess air coefficient of the furnace is slightly greater than 1 to ensure that the fuel is fully burned in the furnace, and the generated high-temperature flue gas enters the tail flue. , Flow through the heating surface at the tail of all levels. When the boiler load decreases, the amount of flue gas decreases, the flow velocity of the flue at the tail decreases, the heat transfer coefficient decreases, and the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com