Temperature and humidity control method and control system for air conditioners in coating workshops

A technology of humidity control and air-conditioning temperature, applied in heating and ventilation control systems, heating and ventilation safety systems, heating methods, etc. Can accurately control temperature and humidity and other issues to achieve the effect of saving energy and improving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Embodiment 1 A kind of air-conditioning temperature and humidity control method in the painting workshop

[0059] A method for controlling the temperature and humidity of an air conditioner in a painting workshop, the method comprising the following steps: Step 1: Calculate vapor pressure P and absolute humidity X by formula a and formula b respectively; where T represents temperature, Patm represents standard atmospheric pressure, RH Indicates humidity;

[0060] P=14097400000×EXP(-3928.5 / (231.667+T))

[0061] formula a

[0062] X = 0.622 × R H × P P a t m - R H × P

[0063] formula b

[0064] Step 2: Combine absolute humidity X and temperature T together to form a set (X, T);

[006...

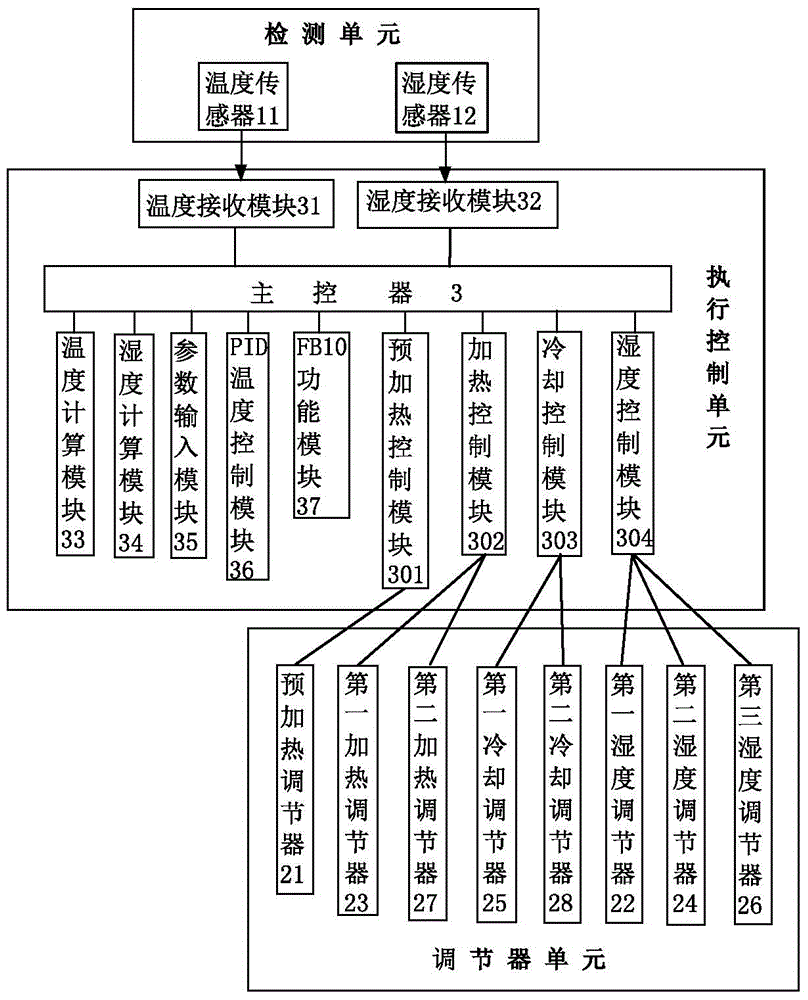

Embodiment 2

[0066] Embodiment 2 A method for controlling the temperature and humidity of an air conditioner in a painting workshop

[0067] A method for controlling the temperature and humidity of an air conditioner in a painting workshop, the method comprising the following steps:

[0068] Step 1: Arrange temperature sensors 11 and humidity sensors 12 at the air inlet and outlet of the air-conditioning unit and the final use position of the air-conditioning unit (such as spray booth, paint mixing room, work station, etc.);

[0069] Second step: the temperature receiving module 31 and the humidity receiving module 32 respectively receive the temperature and humidity collected by the temperature sensor 11 and the humidity sensor 12, and the temperature calculation module 33 and the humidity calculation module 24 calculate the received temperature and humidity respectively to obtain the average temperature T AE and average humidity RH AE ;

[0070] Step 3: The parameter input module 35 i...

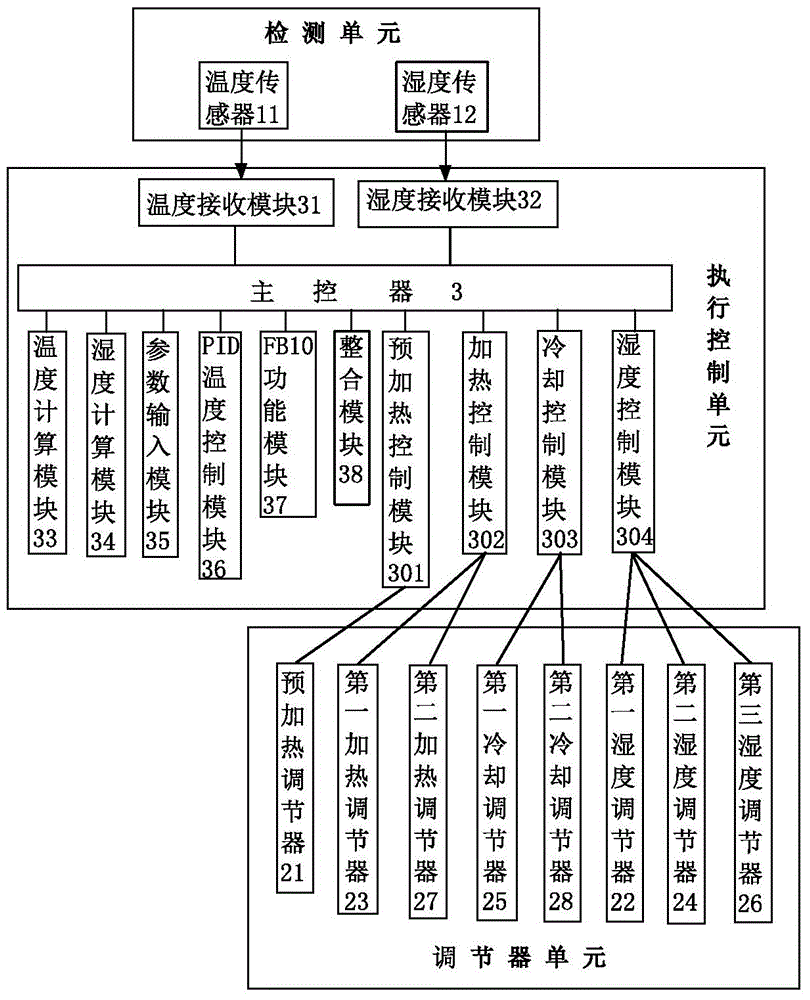

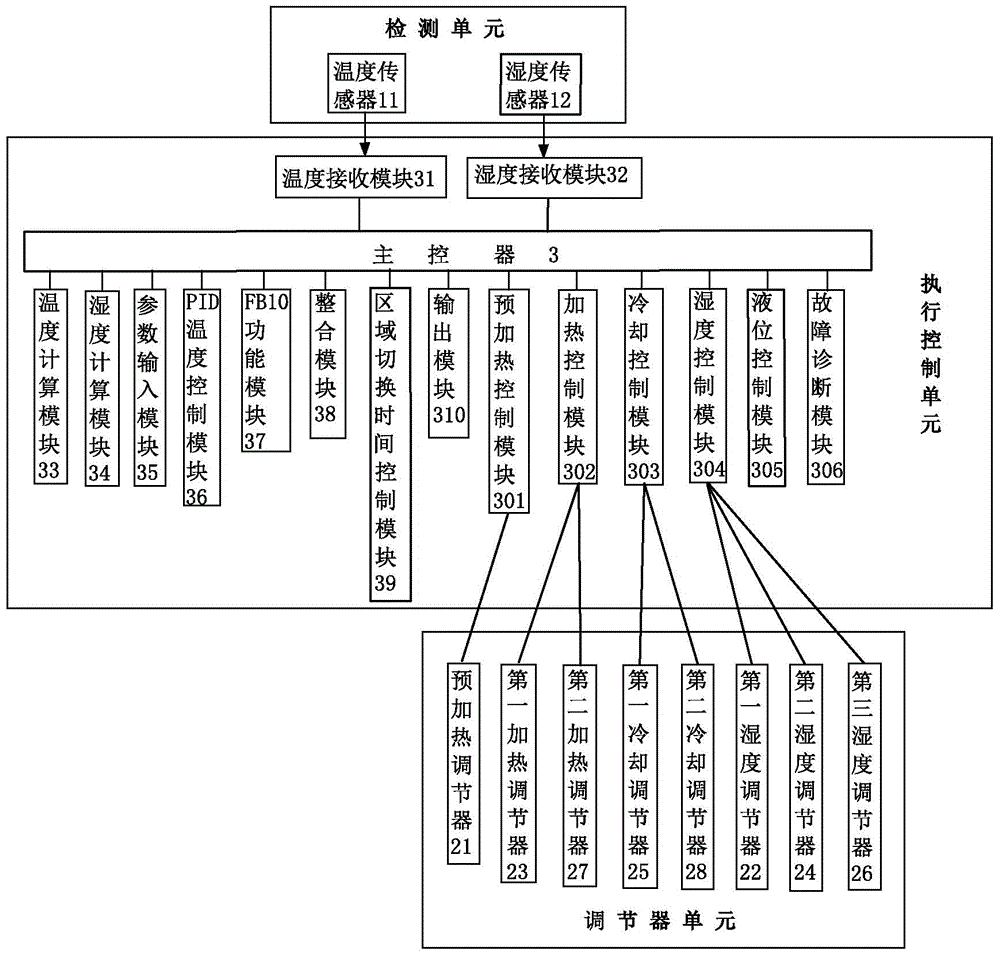

Embodiment 3

[0082] Embodiment 3 A method for controlling the temperature and humidity of an air conditioner in a painting workshop

[0083] An air-conditioning temperature and humidity control method in a painting workshop, the method is different from Embodiment 2 in that the fourth step also includes the FB10 function module 37 calculating the heat H through formula five or six SP or H AE

[0084] h SP =T SP +(2496.7+1.881×T SP )×X SP

[0085] formula five

[0086] h AE =T AE +(2496.7+1.881×T AE )×X AE

[0087] formula six;

[0088] Integrated module 38 for heat H SP or H AE and (X SP , T SP ) or (X AE , T AE ) are integrated in different two-dimensional coordinate ranges, and the FB10 function module 37 judges in which area the corresponding regulator operates among the five areas of the paint shop according to the integration results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com