Heater

A heater and heating zone technology, applied in water heaters, fluid heaters, indirect heat exchangers, etc., can solve problems such as inability to directly use heater hot liquid, inability to achieve heat exchange, inability to solve poor thermal efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following examples illustrate possible implementations of the present invention, but are not intended to limit the protection scope of the present invention.

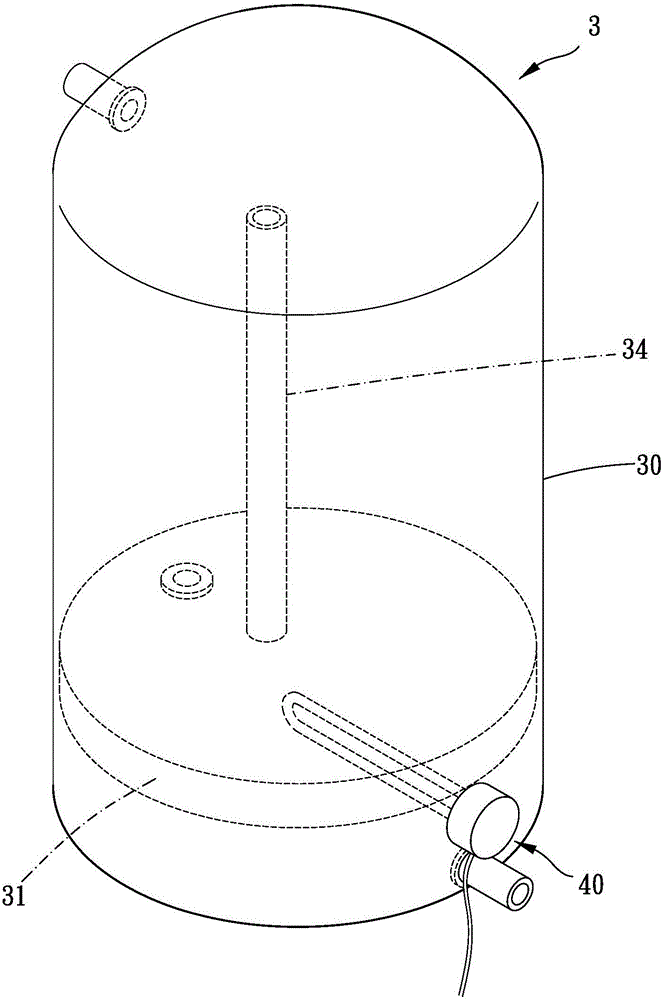

[0031] See Figure 3 to Figure 5 , which shows a preferred embodiment of the present invention, the heater 3 of the present invention includes a cylinder 30 and a heating device 40 .

[0032] The inside of the cylinder 30 is provided with a heat insulating portion 31, a heating area 32 and a non-heating area 33 located on opposite sides of the heat insulating portion 31, a heat insulating portion 31 and connected to the heating area 32 And the heat flow conduit 34 of the non-heating zone 33, and a cold flow channel 35 communicating with the heating zone 32 and the non-heating zone 33, the cylinder 30 is also provided with a water inlet 36 and the inside of the cylinder 30 A water outlet 37 , the heat flow conduit 34 extends from the heating zone 32 toward the water outlet 37 . The heating device 40 (such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com