An experimental method for testing the amount of metal deformation inside a billet during rolling

An experimental method and metal deformation technology, applied in measuring devices, instruments, etc., can solve problems such as low accuracy of experimental results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] This example takes the experiment of measuring the amount of ductile deformation of the central layer and surface metal of the billet after two rolling passes of the Q235 billet at 1200°C as an example to illustrate an experiment for testing the amount of metal deformation inside the billet during the rolling process. Methods and specific implementation steps, the experiment of this embodiment is carried out in the reversible hot rolling test machine of the pilot plant of Shougang Technology Research Institute.

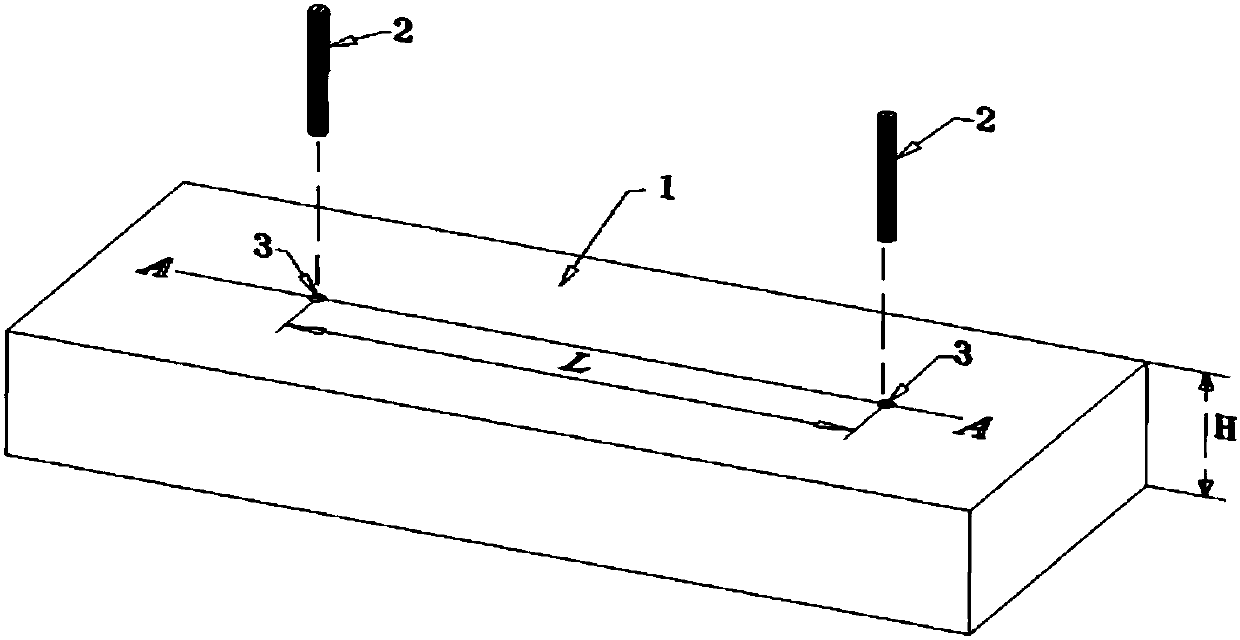

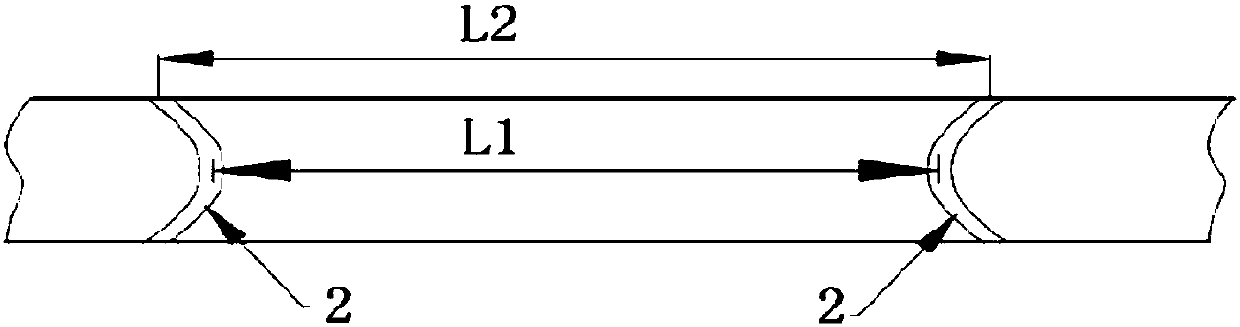

[0016] 1. See figure 1 , the steel billet 1 with the prefabricated screw hole 3 was processed and manufactured by using the steel billet of the grade Q235. Experimental billet 1 has a thickness of 80 mm, a width of 150 mm, and a length of 360 mm. Two prefabricated screw holes 3 perpendicular to the upper surface and having internal threads are made on the centerline of the width of experimental billet 1. On the upper and lower surfaces, the distance between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com