High-temperature creep deformation prediction method

A technology of high-temperature creep and prediction methods, which is applied to measuring devices, using stable tension/pressure to test the strength of materials, instruments, etc., can solve problems such as influence and dispersion of material properties, and achieve shortening experiment time and solving volatility large, improved accuracy and stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A specific scheme of a high-temperature creep deformation prediction method based on a short-time creep experiment in the present invention is given in detail by the following examples.

[0055] Select P92 to carry out experiments and life prediction, including the following steps:

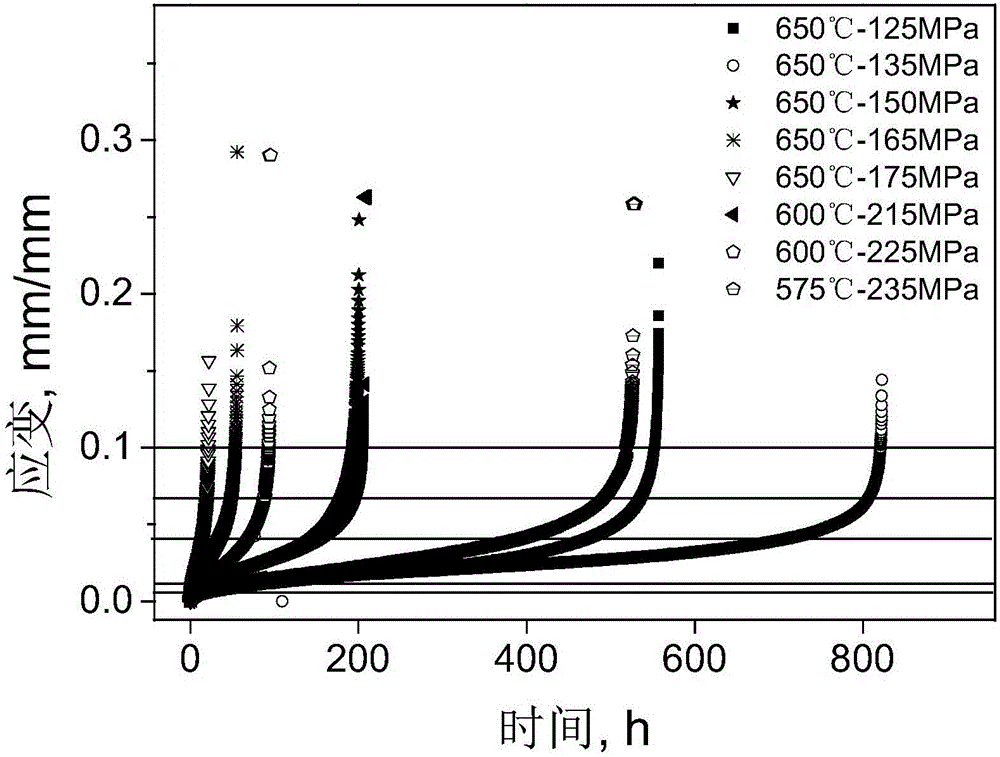

[0056] 1) Respectively at 575℃ 1 under, 235MPa 8 ;600℃ 2 under, 215MPa 6 ,225MPa 7 ;650℃ 3 under, 125MPa 1 ,135MPa 2 ,150MPa 3 ,165MPa 4 ,175MPa 5 ; Carry out the creep test and obtain as figure 1 The creep experimental data are shown. The temperature fluctuation during the experiment is less than 1°C; the strain range of the creep experiment data is 0.1%-20%, and the creep experiment data is the sample deformation value and the time corresponding to the sample deformation value.

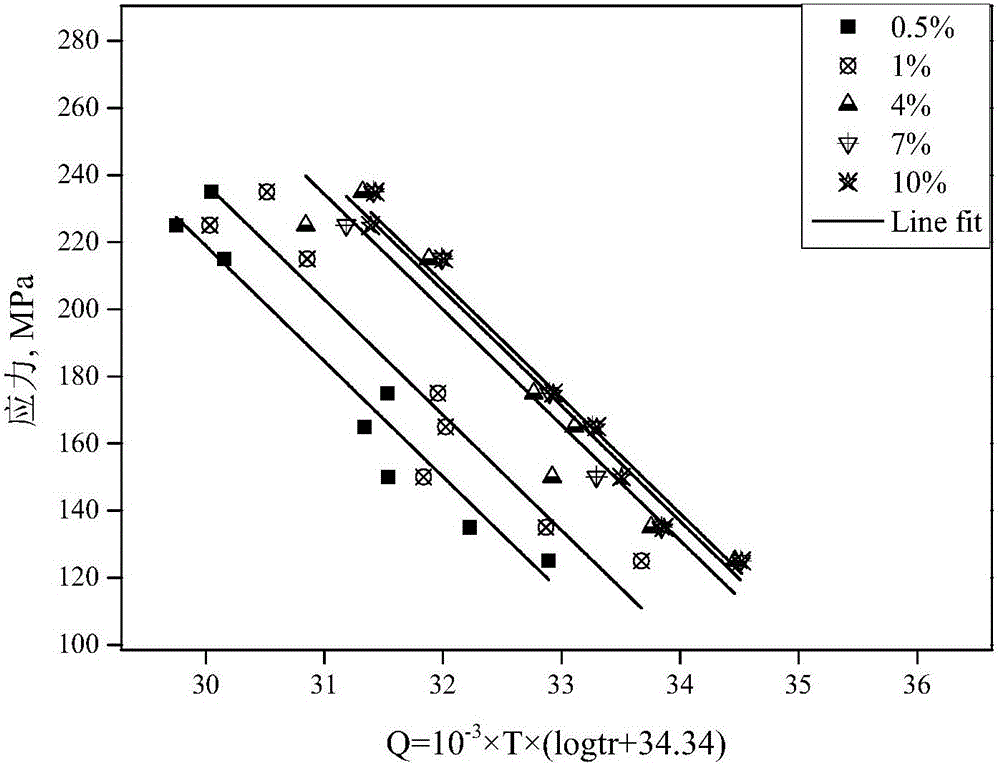

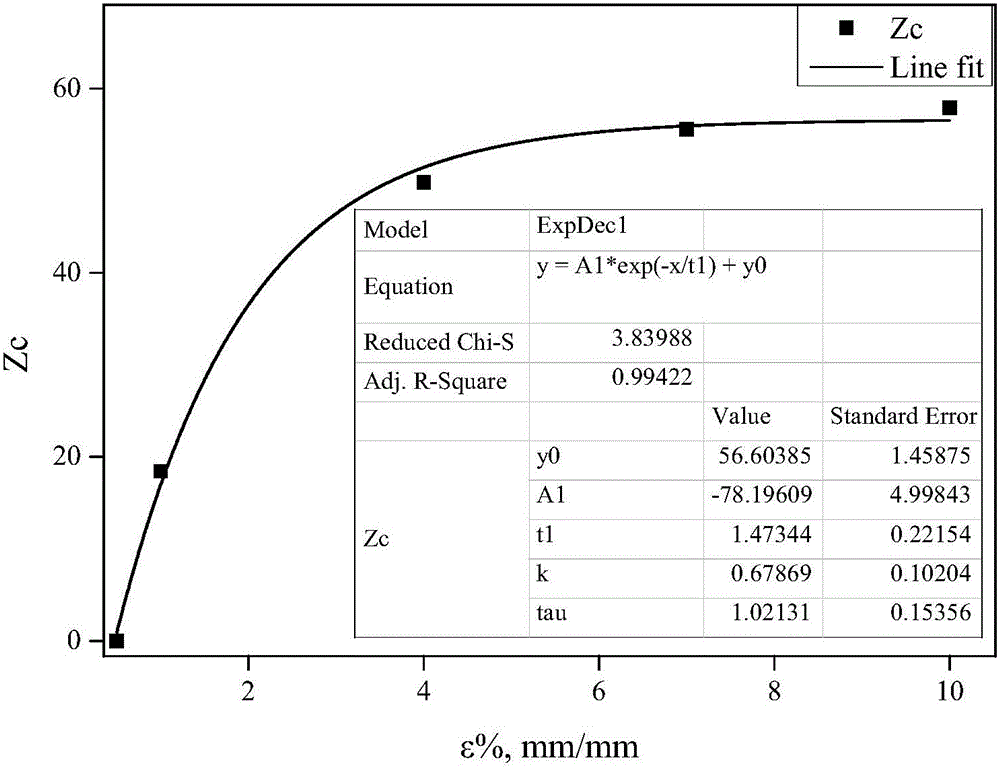

[0057] 2) Select different creep strains from small to large creep strains according to the creep experimental data in each creep experiment in step 1), namely: 0.5% 1 ,1% 2 , 4% 3 , 7% 4 , 10% 5...

Embodiment 2

[0071] A specific scheme of a high-temperature creep deformation prediction method based on a short-time creep experiment in the present invention is given in detail by the following examples.

[0072] Select P92 steel to carry out experiments and life prediction, including the following steps:

[0073] 1) Respectively at 575℃ 1 under, 235MPa 8 ;600℃ 2 under, 215MPa6 ,225MPa 7 ;650℃ 3 Under, 125MPa 1 ,135MPa 2 ,150MPa 3 ,165MPa 4 ,175MPa 5 ; Carried out the creep experiment, obtained as Image 6 The creep test data are shown. The temperature fluctuation during the experiment is less than 1°C; the strain range of the creep test data is 0.1%-20%, and the creep test data is the deformation value of the sample and the time corresponding to the deformation value of the sample.

[0074] 2) The creep experiment data in each creep experiment in step 1) is selected different creep strains according to the creep strain from small to large, namely: 0.5% 1 ,1% 2 , 4% 3 , 7% ...

Embodiment 3

[0088] The specific scheme of a high-temperature creep deformation prediction method based on short-term creep experiments in the present invention is given in detail by the following examples.

[0089] Select HP heat-resistant steel to carry out experiments and life prediction, including the following steps:

[0090] 1) respectively at 1000℃ 1 lower, 32MPa 1 、35MPa 2 、37MPa 3 、38MPa 4 ;980°C 2 lower, 42MPa 5 ;950℃ 3 Below, 50MPa 6 ,900℃ 4 ,60MPa 7 ; The creep test was carried out, and the obtained results were as follows: Figure 11 Creep test data shown. The temperature fluctuation during the experiment is less than 1°C; the strain range of the creep test data is 0.1%-20%, and the creep test data is the deformation value of the sample and the time corresponding to the deformation value of the sample.

[0091] 2) The creep experiment data in each creep experiment in step 1) is selected different creep strains according to the creep strain from small to large, name...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com