Manufacturing method for profile steel used for protective seal doorframe

A manufacturing method and technology of section steel, applied in the direction of metal rolling, etc., can solve the problems of affecting the airtight effect, difficult to eliminate internal stress, difficult to ensure height, etc., and achieve the effect of eliminating welding process, low cost and less production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0033] The manufacture method of section steel for protective sealing door frame of the present invention comprises the following steps:

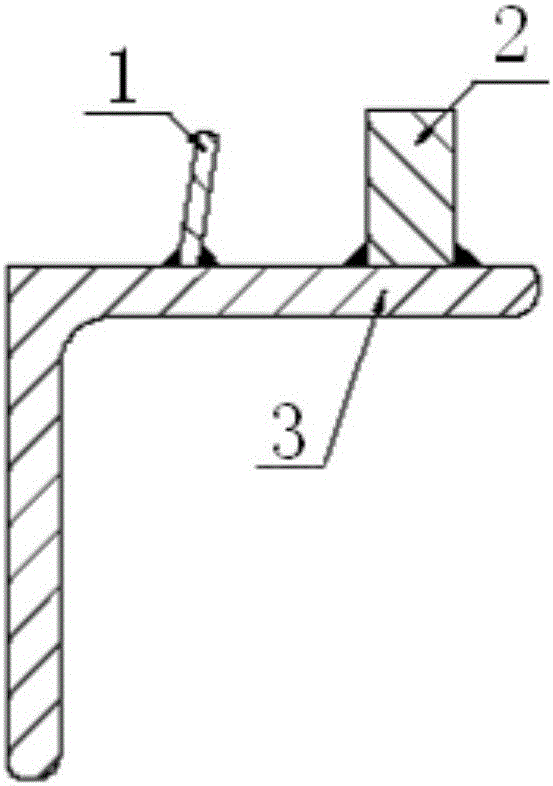

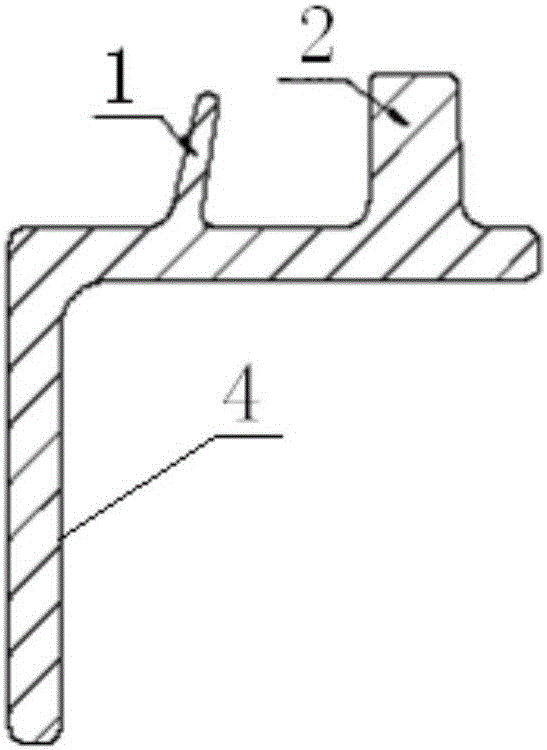

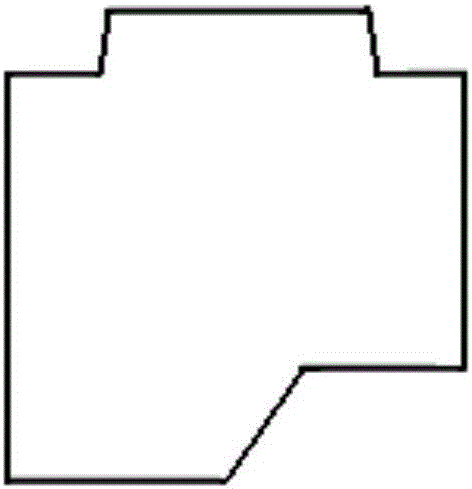

[0034] 1) Select the billet as the raw material, through the first hot rolling process and the second hot rolling process, adopt the method of extension, pre-roll the upper surface and one side of the raw material into a stepped shape, and prepare for strong stretching; Figure 3a , 3b shown.

[0035] 2) Through the third hot rolling process, the stepped side is extended, and the forced widening is carried out while extending, so that it forms a sufficiently long oblique rib 1; as Figure 3c shown.

[0036] 3) Turn the raw material counterclockwise at 90 degrees, and use the fourth cutting process to cut the upper and lower parts of the raw material, so that a vertical rib 2 is for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com