Packing machine

A technology of packaging machine and cutting mechanism, which is applied in the fields of packaging, strapping machine parts, metal processing, etc., which can solve the problems of unable to pack two bags of formed roll paper at the same time, low labor cost, and low output rate, so as to improve packaging efficiency, reduce labor costs, and increase output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

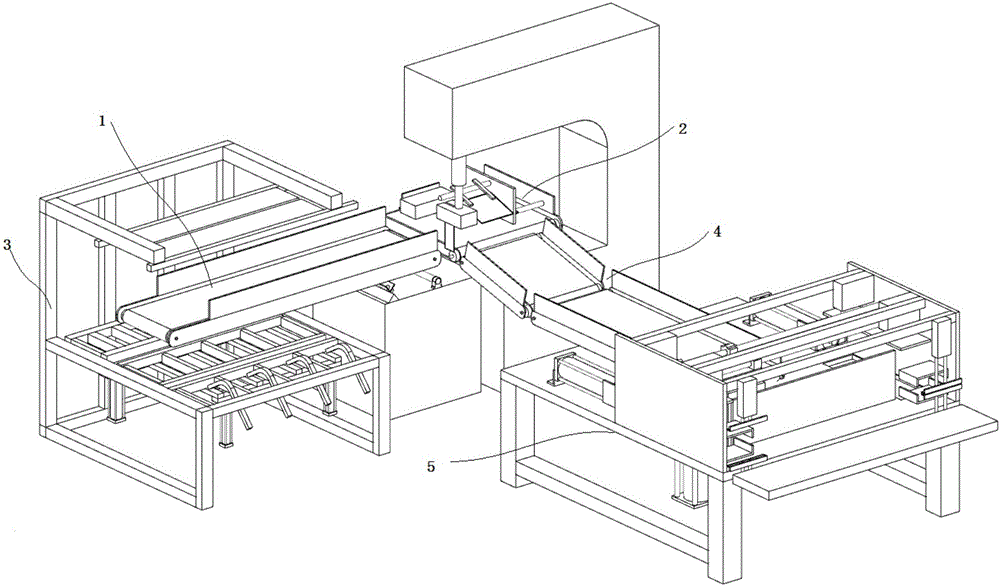

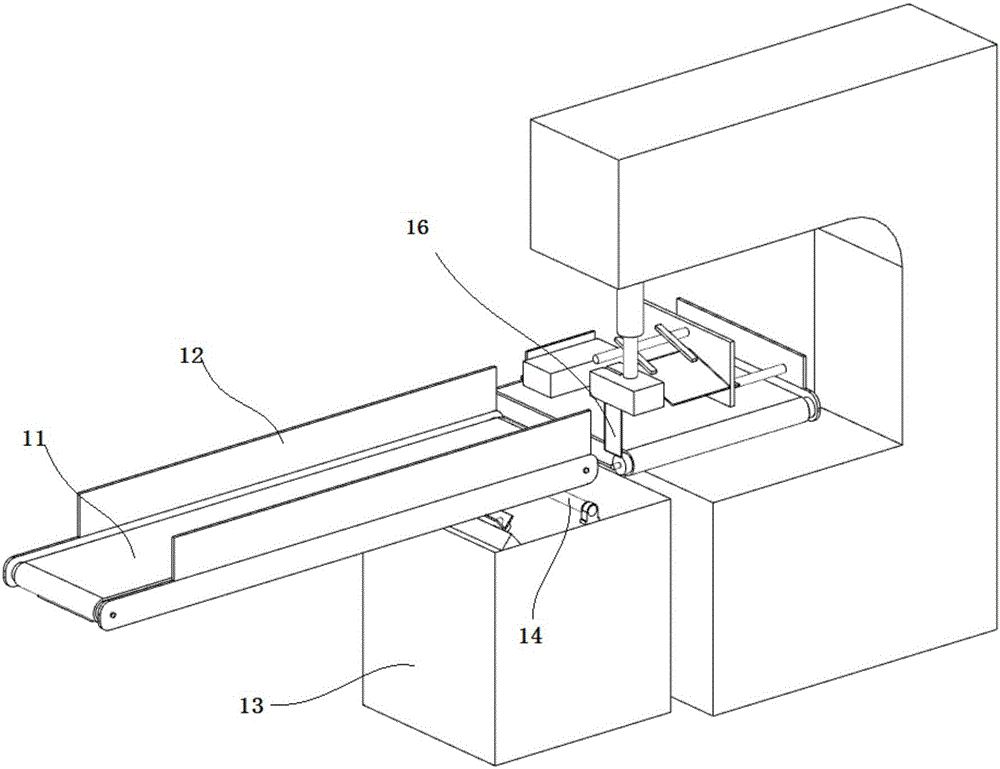

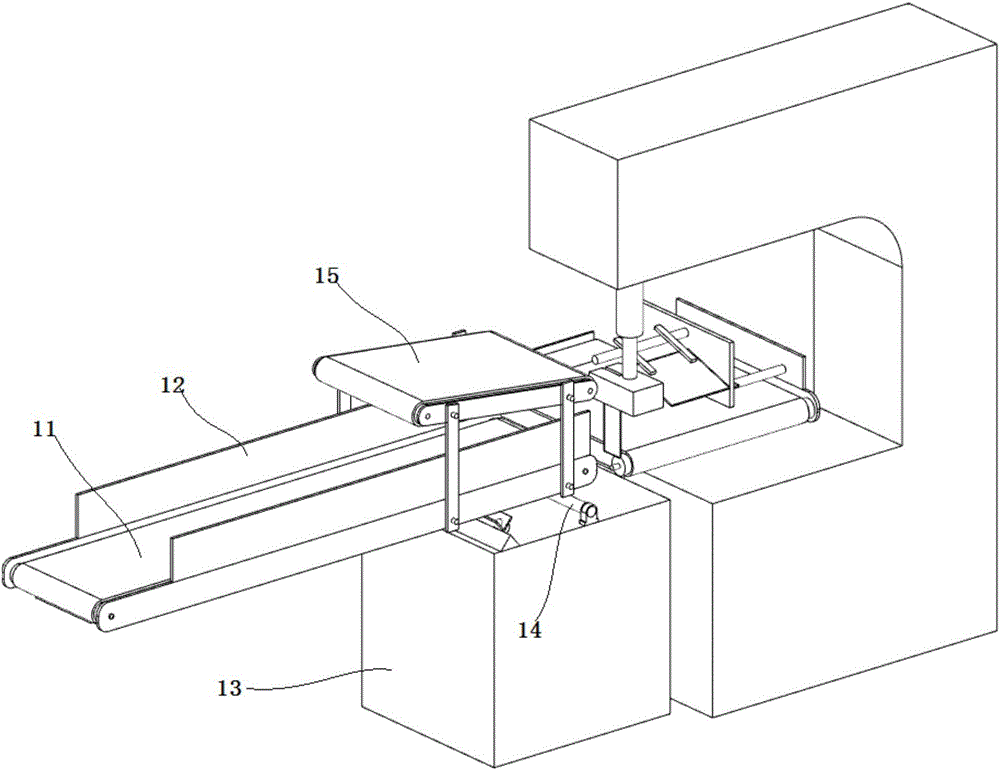

[0035] Such as figure 1 As shown, it is a schematic diagram of the overall structure of the packaging machine of the present invention, which is mainly composed of a feeding mechanism 3, a first conveying part 1, a cutting mechanism 2, a second conveying part 4 and a packaging mechanism 5, as figure 2 As shown, the first transmission part 1 includes a conveyor belt A11, a baffle A12, a box body 13 and a slide rail 14, the baffle plate A12 is symmetrically distributed on both sides of the conveyor belt A11, and the box body 13 is provided with a slide rail 14, The lower end of the conveyor belt A11 is movably connected to the box body 13 through the slide rail 14. The conveyor belt A11 is used to transport the long roll paper provided by the feeding mechanism 3, and the conveyor belt A11 can transport multiple long strips placed side by side. Shape roll paper, one end of conveyor belt A11 is connected with cutting mechanism 2.

[0036] Such as Figure 4 As shown, the cutting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com