One-direction blocking mechanism of roller bed conveyor

A material stop mechanism and conveyor technology, applied in the direction of rollers, transportation and packaging, can solve the problems of difficult control of elastic force, low reliability, easy failure of springs, etc., and achieve the effect of simple structure and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

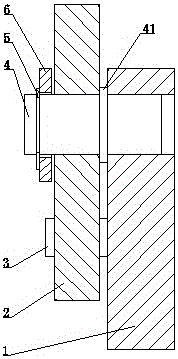

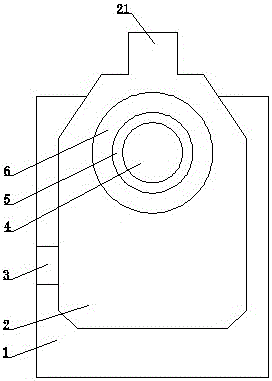

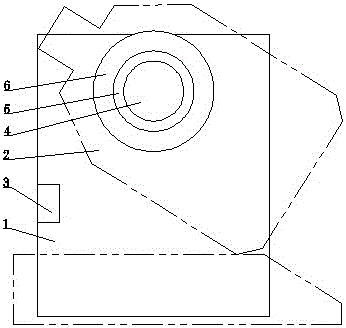

[0009] see Figure 1 to Figure 3 , the present invention includes a seat plate 1, a baffle plate 2, a limit block 3, a rotating shaft 4, a baffle ring 5 and a washer 6, the upper part of the baffle plate 2 is provided with a rectangular stopper 21, and the middle of the rotating shaft 4 is provided with There is an annular boss 41, the right part of the rotating shaft 4 is installed in the hole of the seat plate 1, the baffle plate 2 and the washer 6 are sequentially installed on the left part of the rotating shaft 4 from right to left, and the retaining ring 5 is installed In the annular groove on the left end of the rotating shaft 4, the limit block 3 is installed at the inner position of the left side of the baffle plate 2. The weight of the baffle plate 2 at the lower part of the rotating shaft 4 is heavier than the weight at the upper part of the rotating shaft 4. . An interference fit is adopted between the right part of the rotating shaft 4 and the hole of the seat pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com