Water-resistant silica-alumina gel particle product and production method thereof

A silica-alumina gel and gel technology, which is applied in the direction of silica, ceramic products, silica, etc., can solve the problems of poor water resistance and bursting when exposed to water, and achieve high compressive strength, low regenerative breakage rate, and long life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0015] Formulated with SiO 2 10%~14%, Al(OH) 3 2.0% to 3.0% alkali solution, 8% to 12% sulfuric acid solution and 2.5% to 4.5% aluminum sulfate solution for use; nitric acid or hydrochloric acid solution can also be used instead of sulfuric acid solution, and sulfuric acid solution is safer.

[0016] Under the pressure of 0.1-1.0 MPa, the above solution undergoes a step-by-step reaction through a suspension granulation device, is sprayed into the air through a nozzle, and then polycondenses into granular gel particles. Then the gel particles are sequentially processed through the following treatment processes:

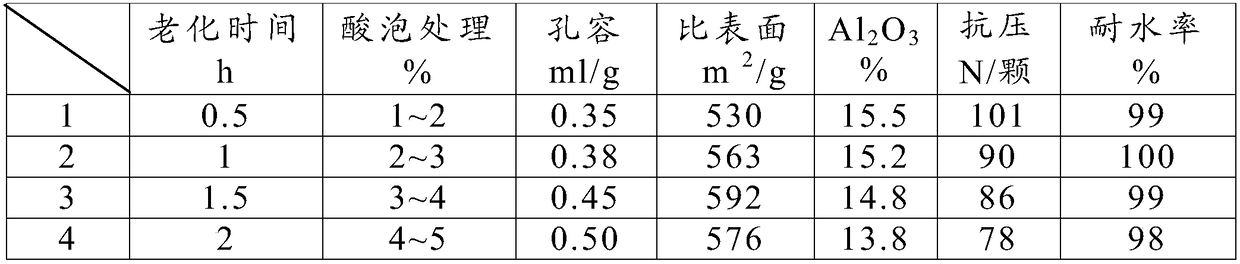

[0017] Aging process: put the gel particles into an aging tank filled with hot water at 20-80°C, and soak for 0.5-2.0 hours.

[0018] Acid soaking process: Soak the aged gel particles in a solution containing 1-5% of inorganic acid aluminum for 2-10 hours; the inorganic acid aluminum solution is one of sulfuric acid solution, nitric acid solution and hydrochloric aci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com