Biogas power generation and complementary energy recovery system

A technology of waste energy recovery and biogas power generation, which is applied in gas production bioreactors, bioreactor/fermenter combinations, bioreactors/fermenters for specific purposes, etc. Short life, affecting granulation efficiency and other problems, to achieve high granulation efficiency, maintaining a virtuous cycle, and good granule integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

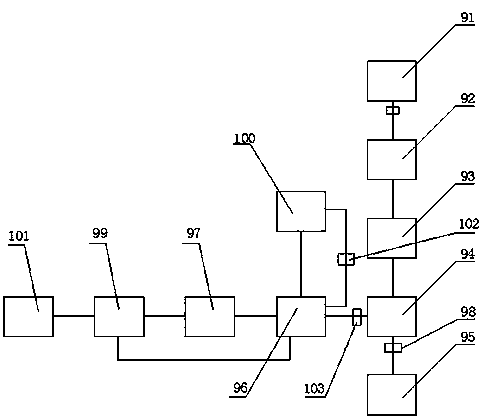

[0031] As shown in the drawings, the present invention includes a double-membrane gas cabinet 91, a biogas decarbonization device 92, a biogas dehydration device 93, a biogas booster pump 94, a granulator 95, a biogas generator set 96, a waste heat boiler 97, and a softened water treatment device 99 and hot water tank 100,

[0032] The biogas output port of the double-membrane gas cabinet 91 is connected with the air inlet of the biogas decarburization device 92 through the air pump, and the gas outlet of the biogas decarbonization device 92 is connected with the inlet port of the biogas dehydration device 93, and the biogas dehydration device 93 The gas outlet is connected to the air inlet of the biogas booster pump 94, and the outlet of the A gas pump of the biogas booster pump 94 is provided with a flame arrester 98, and the biogas booster pump 94 passes through the dry hot air inlet of the biogas burner and the granulator 95 are connected,

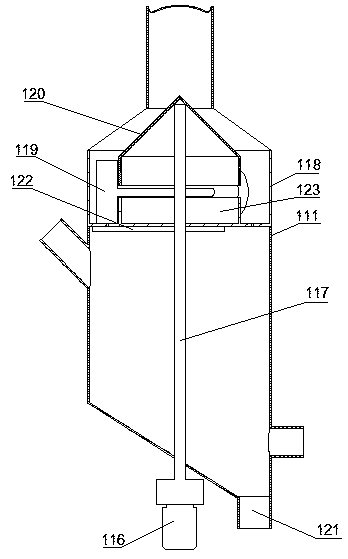

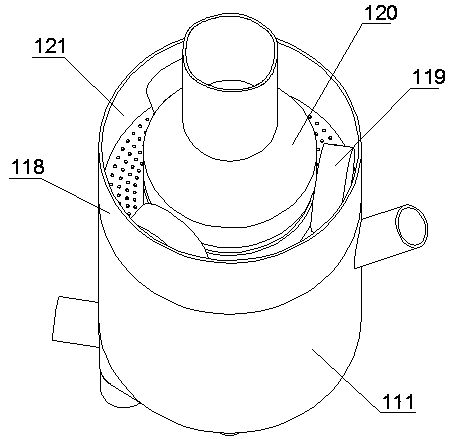

[0033] The granulator 95 compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com