Cooling sealing system

A sealing system and sealing device technology, applied in the direction of cooling device, etc., can solve the problems of harmful influence of cooling wall cooling effect, not much improvement, pollution of circulating water of furnace body, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

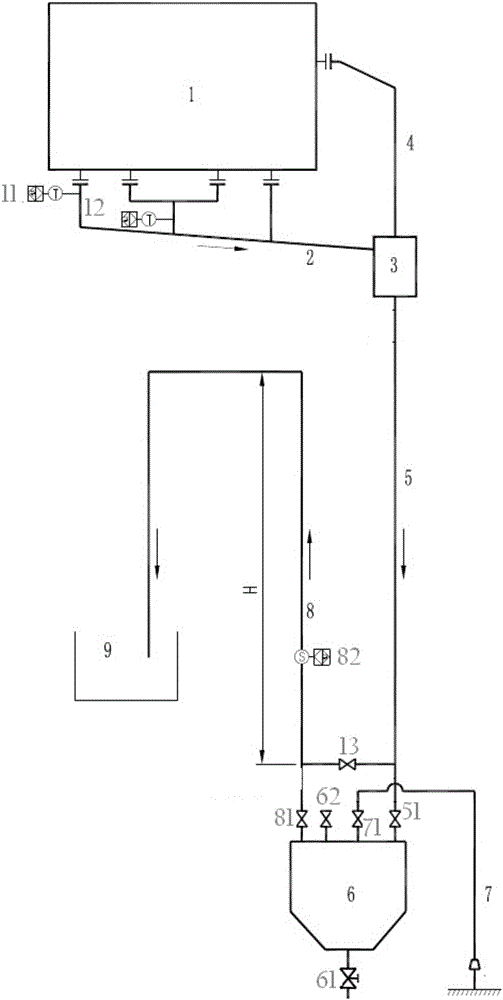

[0023] In this embodiment, the cooling and sealing system is described by taking the airtight box / distributor applied to the top charging equipment of a blast furnace as an example.

[0024] The cooling and sealing system of this embodiment includes an air-water separation device and a U-shaped sealing device sequentially arranged between the water outlet of the air-tight water-cooling equipment 1 of the air-tight box / distributor and the drainage tank 9 .

[0025] The gas-water separation device includes a water outlet pipe 12 connected to an airtight water-cooled water outlet, a water outlet main pipe 2 , a gas-water separation tank 3 and an air return pipe 4 , and also includes a temperature detection device 11 arranged on the water outlet pipe 12 . The water outlet pipe 12 of the cooling water is connected to the water outlet main pipe 2, and communicates with the gas-water separation tank 3 through the water outlet main pipe 2, and the air return pipe 4 connects the air out...

Embodiment 2

[0035] The cooling and sealing system of this embodiment improves the U-shaped pipeline system on the basis of Embodiment 1, and realizes the sewage discharge, water replenishment and cleaning of the sedimentation tank 6 without affecting the work of the system.

[0036] In the cooling and sealing system of this embodiment, a connecting pipe is arranged between the inlet pipe 5 of the sedimentation tank and the return pipe 8, and a connecting valve 13 is arranged on the connecting pipe; the inlet pipe 5 of the sedimentation tank and the return pipe On 8, switch valves 51 and 81 are respectively arranged downstream of the communication pipe, a blowdown valve 61 is arranged at the bottom end of the sedimentation tank 6, and an exhaust valve 62 is arranged at the upper end of the sedimentation tank.

[0037] In order to clean the settling tank 6, the settling tank 6 is also connected with a water replenishment device, and the water replenishment device includes a water replenishme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com