Application of ultrasonic shot-peening to metal surface alloying

A technology of ultrasonic shot peening and metal surface, applied in metal material coating process, pressure inorganic powder coating, coating, etc., can solve the problems of narrow application area, cumbersome operation, complicated process, etc. Good effect of internal stress and metallographic structure compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

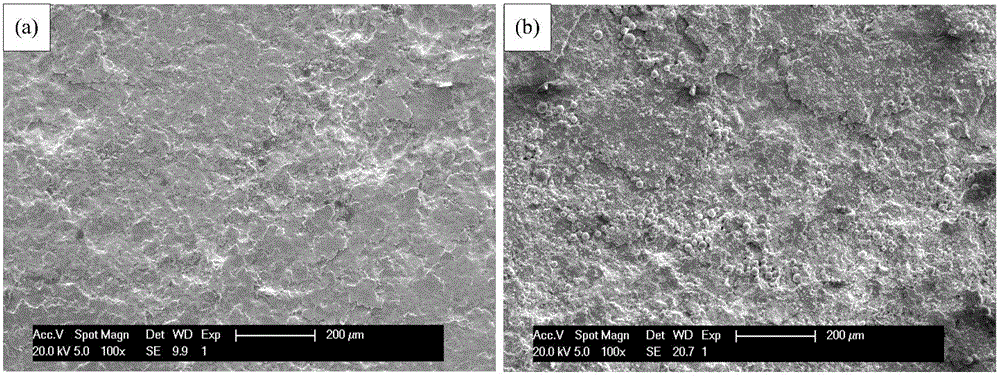

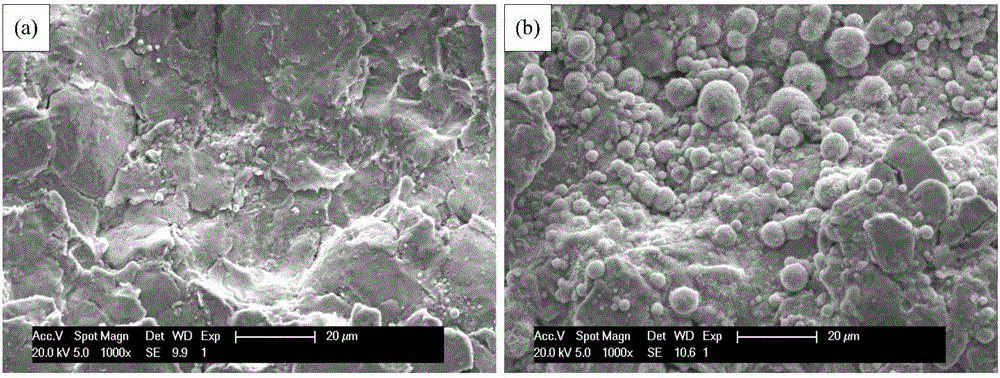

[0020] The surface alloying method of adding nickel powder on the surface of pure iron-based substrates after ultrasonic shot peening is carried out according to the following steps:

[0021] (1) The experimental materials are industrial pure iron and Ni60 powder, in which the iron content of the pure iron-based substrate is Fe≥90%, and the particle size of the nickel powder is 300-400 mesh. The size of the pure iron-based substrate is 200×200×4mm, and the pure iron-based substrate is repeatedly polished with 400-grit sandpaper to obtain a fresh metal surface. Clean the surface of the pure iron-based substrate with alcohol to make it clean, and let it dry naturally.

[0022] (2) Sprinkle the nickel powder evenly on the surface of the pure iron-based substrate, and the thickness of the nickel powder is 1-2mm. Shot peening is performed using ultrasonic shot peening equipment. Selected shot peening operating parameters: the shot peening power is characterized by the current val...

Embodiment 2

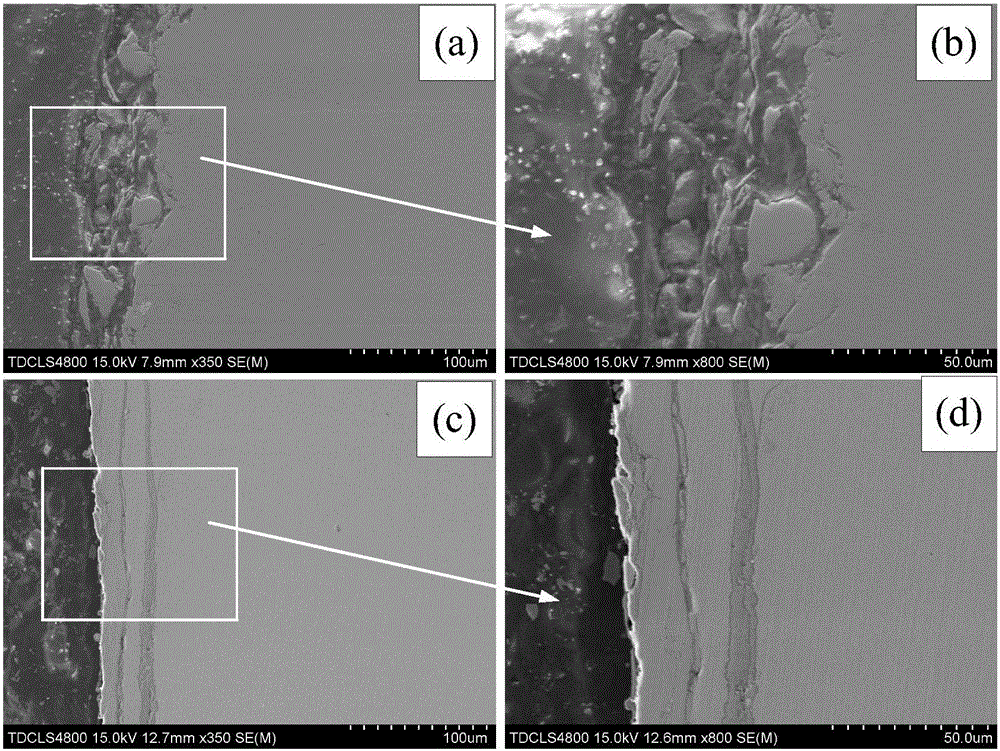

[0026] Embodiment 2 uses low-carbon steel and tungsten carbide powder, the particle size is 200 mesh, other steps and parameters are consistent with embodiment 1, through the alloying of tungsten carbide on the surface of low-carbon steel, the wear resistance of its surface has been improved. Effective improvement. The friction and wear experiment was carried out using the model MMW-1 configuration control universal friction and wear testing machine. Under the load of 15N, the friction coefficient of tungsten carbide powder was increased by nearly 10 times compared with the untreated material after ultrasonic shot peening. ; When the load is 35N, the friction coefficient of the added tungsten carbide powder after ultrasonic shot peening is nearly 2.6 times higher than that of the untreated material. The present invention has been described as an example above, and it should be noted that, without departing from the core of the present invention, any simple deformation, modifica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com