Large-angle inclined leg pier pouring construction method

A construction method and a large-angle technology, applied in bridges, buildings, bridge parts, etc., can solve the problems of inability to set up supporting structures, small space for the bearing platform, etc., and achieve good overall stability, high positioning accuracy, and small footprint. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

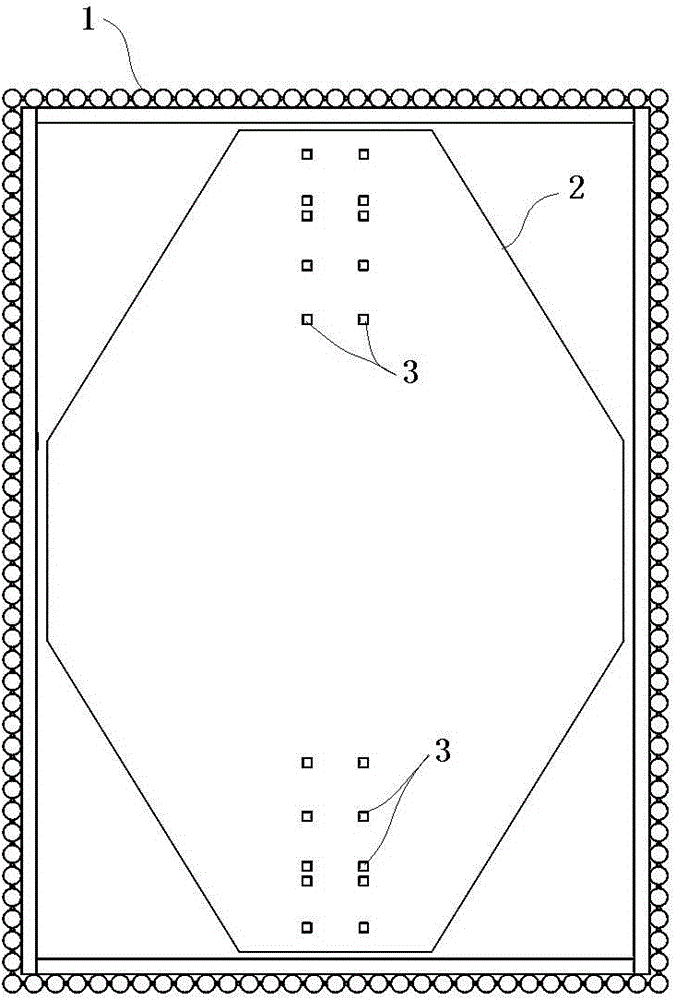

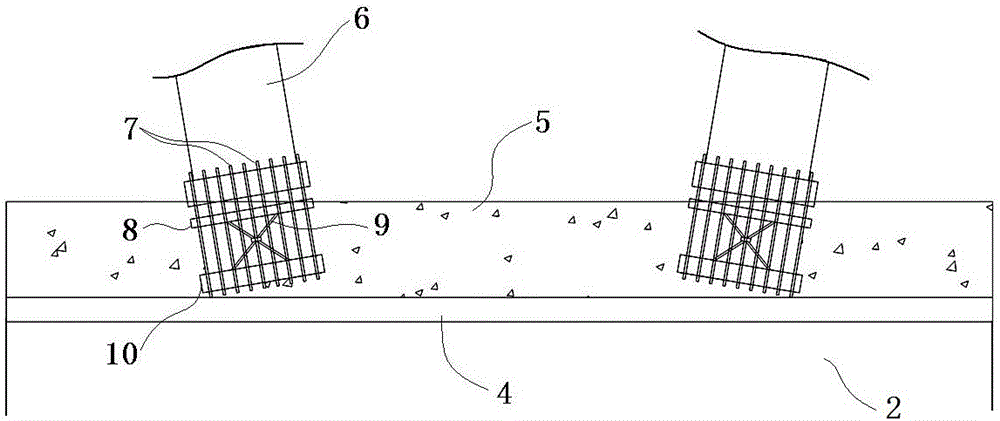

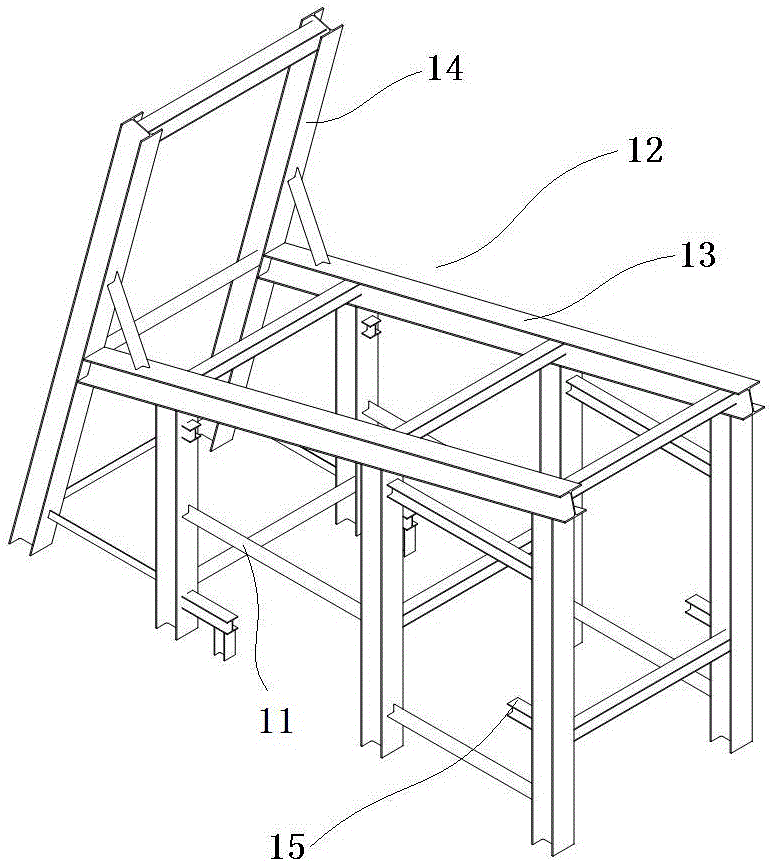

[0021] Example: such as Figure 1-6 As shown, this embodiment specifically relates to a construction method for pouring a large-angle oblique-leg pier. The slope of the pier body 19 is greater than 60°, and the construction method specifically includes the following steps:

[0022] (1) Connect and position the pier foot 6 of the pier body on the basis of the cap 2:

[0023] 1a) if Figure 1-3 As shown, the cap 2 is set in the cofferdam 1. Firstly, the back cover concrete construction of the foundation of the cap 2 is carried out up to the design elevation, and then a number of embedded parts 3 are arranged on the bottom cover concrete of the cap 2 corresponding to the designed positions of the piers. , the number and arrangement positions of the embedded parts 3 correspond to the number and positions of the bottom pipes of the temporary support one by one; after that, the concrete cushion layer 4 of the platform cap 2 is poured on the back cover concrete, and the thickness o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com