Convection type full luminescent lamp and realizing method thereof

A technology for light-emitting lamps and light boards, which is applied to semiconductor devices, light sources, lighting devices, etc. of light-emitting elements, can solve the problems of affecting the use effect, narrow light-emitting angle, poor heat dissipation, etc., and achieves good use effect and large light-emitting angle. , good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

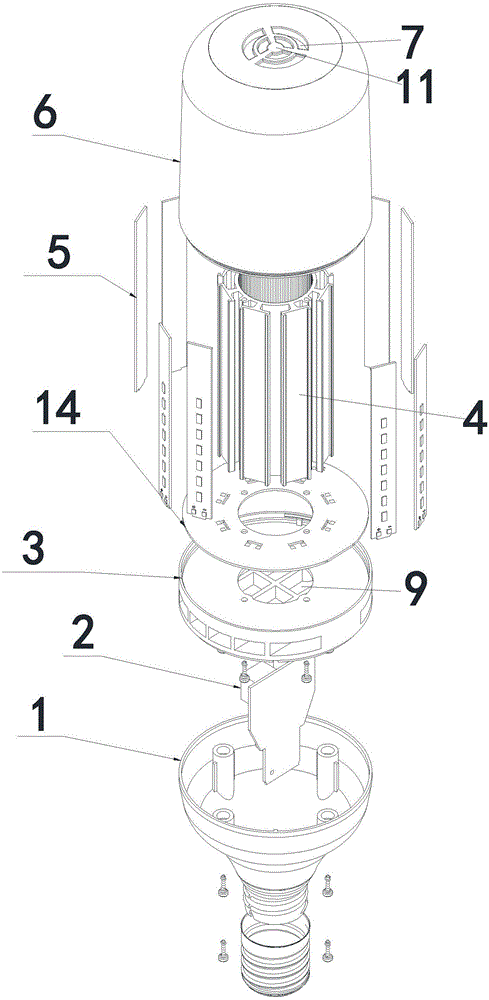

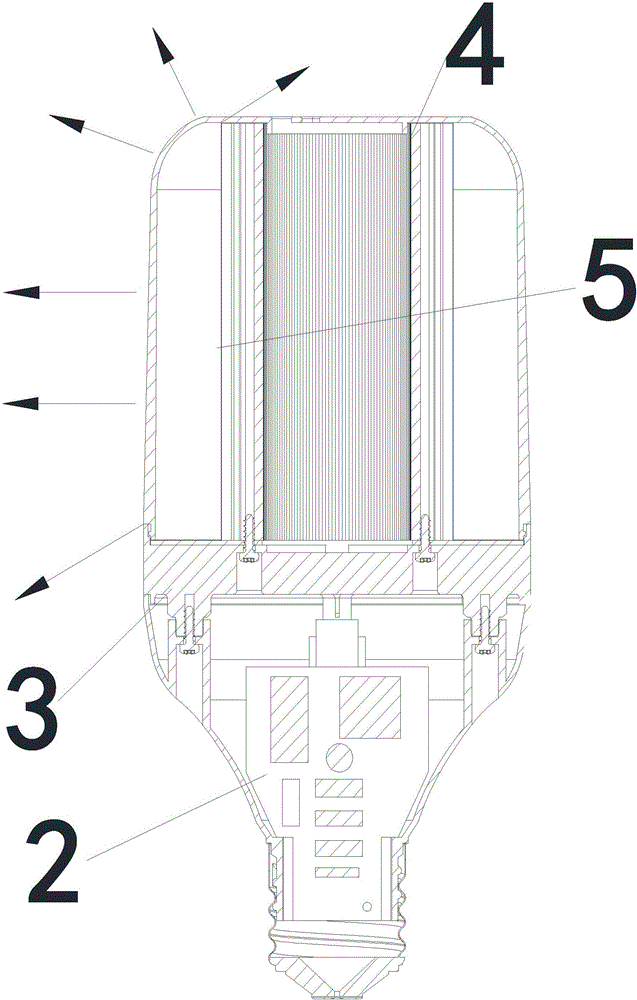

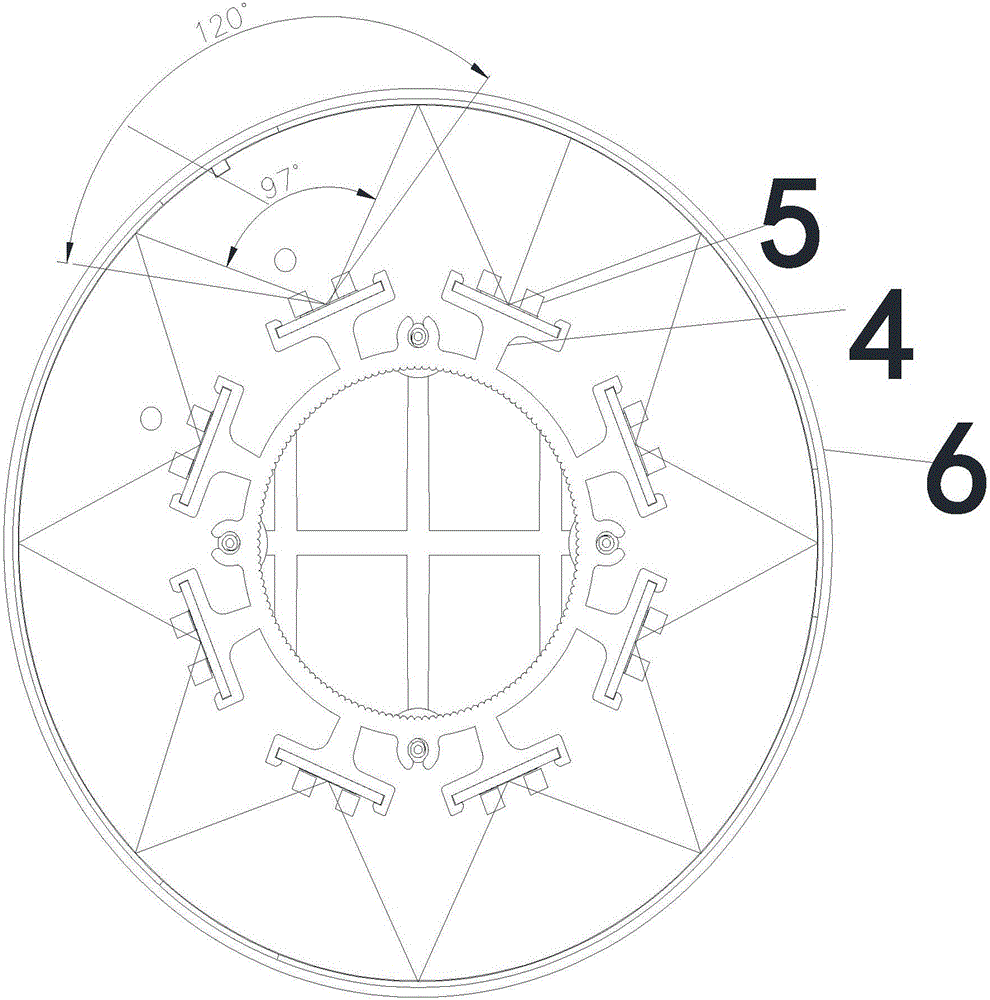

[0045] Such as Figure 1-7 As shown, a convective full-illumination lamp includes a driving seat, a PCB board is arranged inside the driving seat, a connecting piece for air entry is arranged on the upper part of the driving seat, an aluminum extrusion is arranged on the connecting piece, and the aluminum extrusion is Hollow structure, more than 3 light source boards are evenly arranged around the aluminum extrusion, the light source board is covered with a bulb, and the top of the bulb is provided with an air outlet; a convection channel is formed between the connecting piece, the aluminum extrusion, and the air outlet .

[0046] The connector in this embodiment includes a connector body, which is provided with several air inlet holes, the connector body is a hollow structure, the upper part of the connector body is provided with a connector convection hole, and the bottom of the connector body is a sealing plate; A plurality of evenly arranged reinforcing ribs are arranged ...

Embodiment 2

[0060] The difference between this embodiment and Embodiment 1 is that the vertical distance from the light source board to the bulb in this embodiment is 25mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com