Repairable spare part demand prediction method for phased-mission system

A demand forecasting, multi-stage technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as poor forecasting effect of spare parts demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

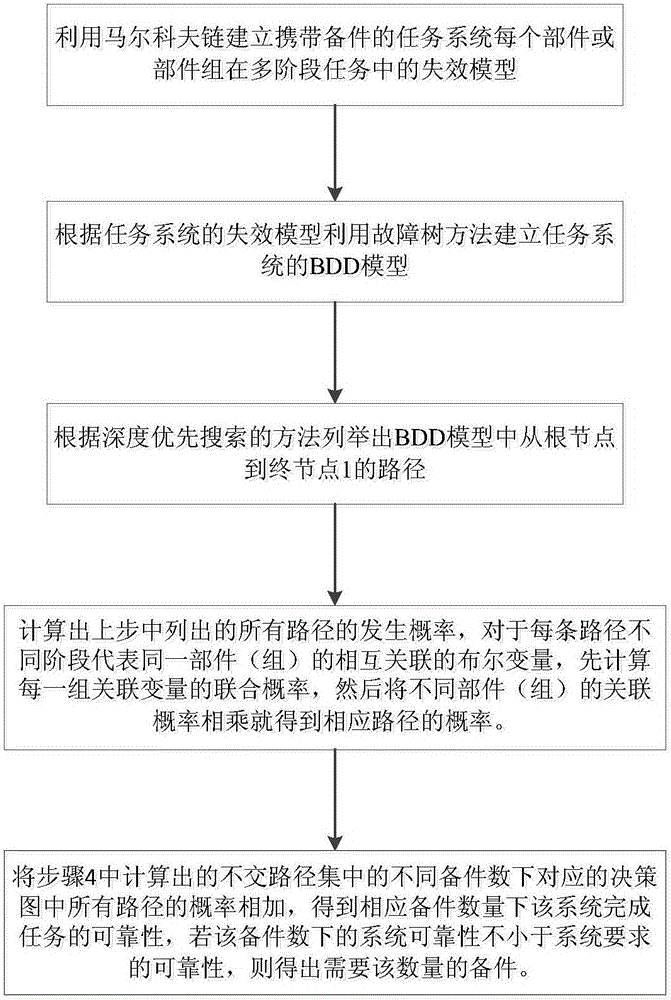

[0061] refer to Figure 1-4 . The specific steps of the repairable spare parts demand forecasting method for the multi-stage mission system of the present invention are as follows:

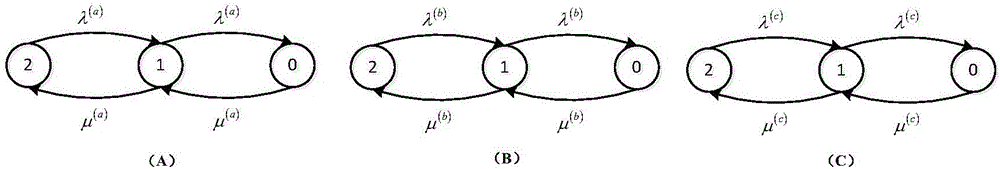

[0062] 1. Use the Markov chain to establish the failure model of each component or component group in the multi-stage task in the mission system carrying repairable spare parts, and consider different components in the equipment system and their corresponding spare parts as a component group as a whole. The specific method is as follows:

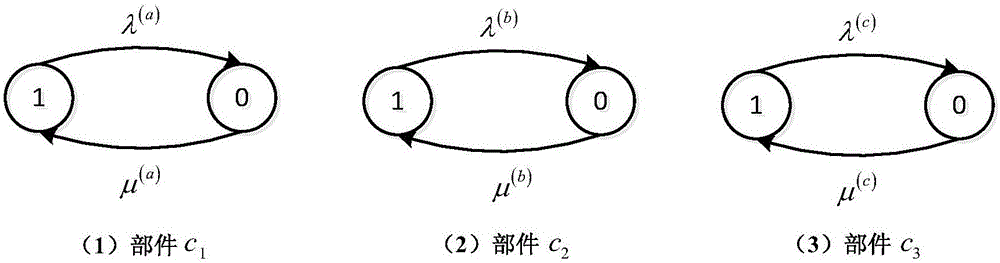

[0063] The radar system participating in the exercise mission contains three types of components c 1 ,c 2 ,c 3 , the exercise task includes two phases of target search and target tracking, and the duration of the two phases is T1 and T2 respectively. When performing a target search task, component c is required 1 works, and component c 2 ,c 3 There is at least one job, and the task structure function at this time is F 1 =c 1 c 2 +c 1 c 3 . When per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com