Ship and boat shafting service life predicating method on the basis of vibration fatigue coupling analysis

A coupling analysis and vibration fatigue technology, applied in the field of marine power plant, can solve the problems of shafting life prediction complexity, reduce the natural frequency of the structure, affect the vibration characteristics of the structure, etc. predicted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0051] 1. Description of the embodiment

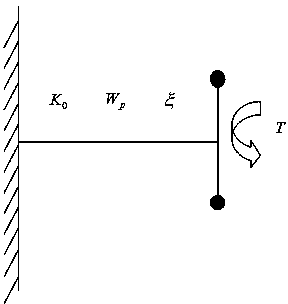

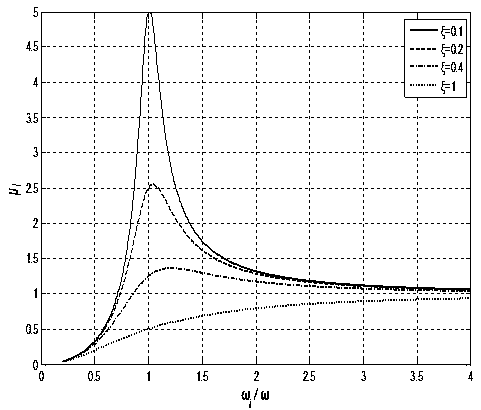

[0052] The propeller of a ship’s two-stroke diesel engine can be simulated by a single-mass torsional vibration system, such as figure 1 shown. Torsional vibration stiffness K when the shaft is not in use 0 =94.336MNm / rad, torsion section coefficient W p =0.0260m 3 , the damping ratio of the shaft ξ=0.1, the moment of inertia of the propeller I=31420Kg m 3 , the periodic disturbance torque T=167.428sin12.4tKN·m acting on the shaft (that is, the periodic disturbance torque amplitude T 0 =167.428KN·m).

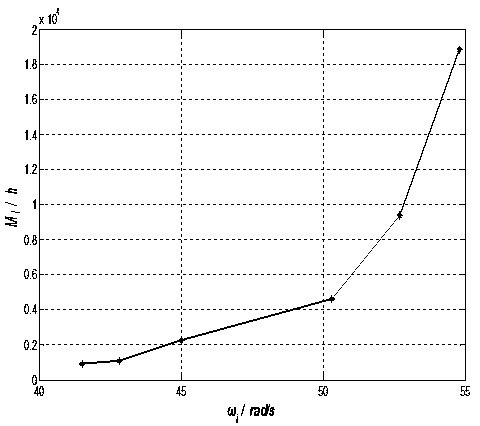

[0053] The shaft fatigue performance curve satisfies: i.e. C=10 11 , m=0.75. The diesel engine is a two-stroke, and one stress cycle makes one revolution, so the diesel engine speed is The number of stress cycles in 1 hour is n r ·60=118.4·60=7104 times, for the sake of clarity, the units of life in the following are converted into hours.

[0054] 2. Calculation results

[0055] The natural frequency of the axis when not in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com