Surface structure and manufacturing method of electric mosquito swatter

An electric mosquito swatter and surface structure technology are applied to devices, applications, and animal husbandry for capturing or killing insects. Excellent waterproof insulation performance, the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

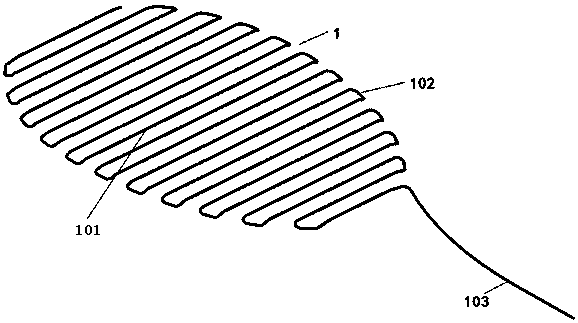

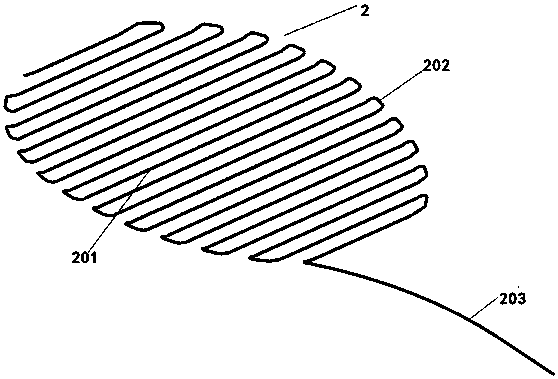

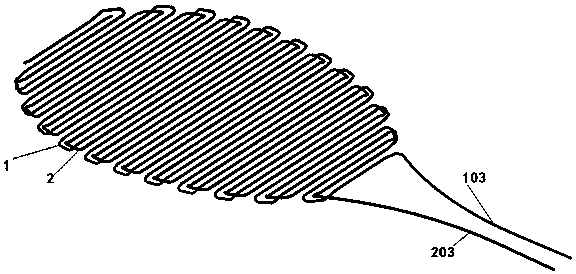

[0018] Such as Figure 1-5 As shown, a racket surface structure of an electric mosquito racket includes a racket frame 3, a mesh surface A1 and a mesh surface B2 arranged in the racket frame 3. The mesh surface A1 and the mesh surface B2 are each reciprocally bent by a metal wire A mesh surface is formed. The mesh surface A1 includes a number of parallel and evenly spaced horizontal portions A101. The adjacent horizontal portions A101 are connected by inflection portions A102. The mesh surface B2 includes a number of parallel and evenly spaced horizontal portions B201. The adjacent horizontal part B201 is connected by the inflection part B202. The end of the last horizontal part A101 is connected to the extension lead A103, and the end of the last horizontal part B201 is connected to the extension lead B203. The mesh surface A1 and the mesh surface B2 are parallel Staggered installation on the same plane, the mesh surface B2 is located above the mesh surface A1, the horizontal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com