Winter jasmine extract and application thereof in preparation of food preservative

A technology of winter jasmine and its extract, which is applied in the field of winter jasmine extract and its application in the preparation of food preservatives, which can solve problems such as adverse effects of food flavor and human side effects, and achieve significant antibacterial and antiseptic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

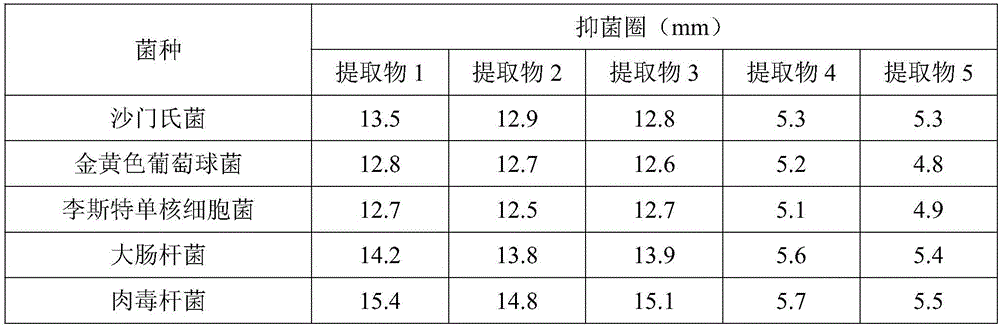

Examples

Embodiment 1

[0016] Embodiment 1: the preparation of winter jasmine extract

[0017] (a) Mix and pulverize 5kg of dried Jasmine and Artemisia capillarye (accounting for 10% of the total weight), extract 3 times (25L×3 times) under reflux with 85% ethanol for 2 hours each time, combine the extracts, and concentrate to Obtain concentrated solution (3L) without alcoholic smell; (b) use petroleum ether (3L×3 times), ethyl acetate (3L×3 times) and water-saturated n-butanol (3L×3 times) successively to step (a) concentrated solution 3 times) extraction, to obtain petroleum ether extract, ethyl acetate extract and n-butanol extract respectively; The column volume was used to remove large polar substances, and then 10 column volumes were eluted with 75% ethanol, and the 75% ethanol eluate was collected and concentrated under reduced pressure.

Embodiment 2

[0018] Embodiment 2: the preparation of winter jasmine extract

[0019] (a) Mix and pulverize 5kg of dried Jasmine and Artemisia capillarye (accounting for 5% of the total weight), extract 3 times (25L×3 times) with 80% ethanol under reflux, each time for 2 hours, combine the extracts, and concentrate to Obtain concentrated solution (3L) without alcoholic smell; (b) use petroleum ether (3L×3 times), ethyl acetate (3L×3 times) and water-saturated n-butanol (3L×3 times) successively to step (a) concentrated solution 3 times) extraction, to obtain petroleum ether extract, ethyl acetate extract and n-butanol extract respectively; The column volume was used to remove large polar substances, and then 12 column volumes were eluted with 70% ethanol, and the 70% ethanol eluate was collected and concentrated under reduced pressure.

Embodiment 3

[0020] Embodiment 3: the preparation of winter jasmine extract

[0021] (a) Mix and pulverize 5 kg of dried Jasmine and Artemisia capillary (accounting for 15% of the total weight), extract 3 times with 90% ethanol under reflux (25L×3 times), each time for 2 hours, combine the extracts, and concentrate to Obtain concentrated solution (3L) without alcoholic smell; (b) use petroleum ether (3L×3 times), ethyl acetate (3L×3 times) and water-saturated n-butanol (3L×3 times) successively to step (a) concentrated solution 3 times) extraction, to obtain petroleum ether extract, ethyl acetate extract and n-butanol extract respectively; The column volume was used to remove large polar substances, and then 8 column volumes were eluted with 80% ethanol, and the 80% ethanol eluate was collected and concentrated under reduced pressure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com