Dual-in-line package chip dismounting device

A dual-in-line packaging and disassembly device technology, which is applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve the problems of complicated operation process, damage, and difficulty in chip removal, and achieve the effect of reducing the heating area and preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in further detail below by embodiment.

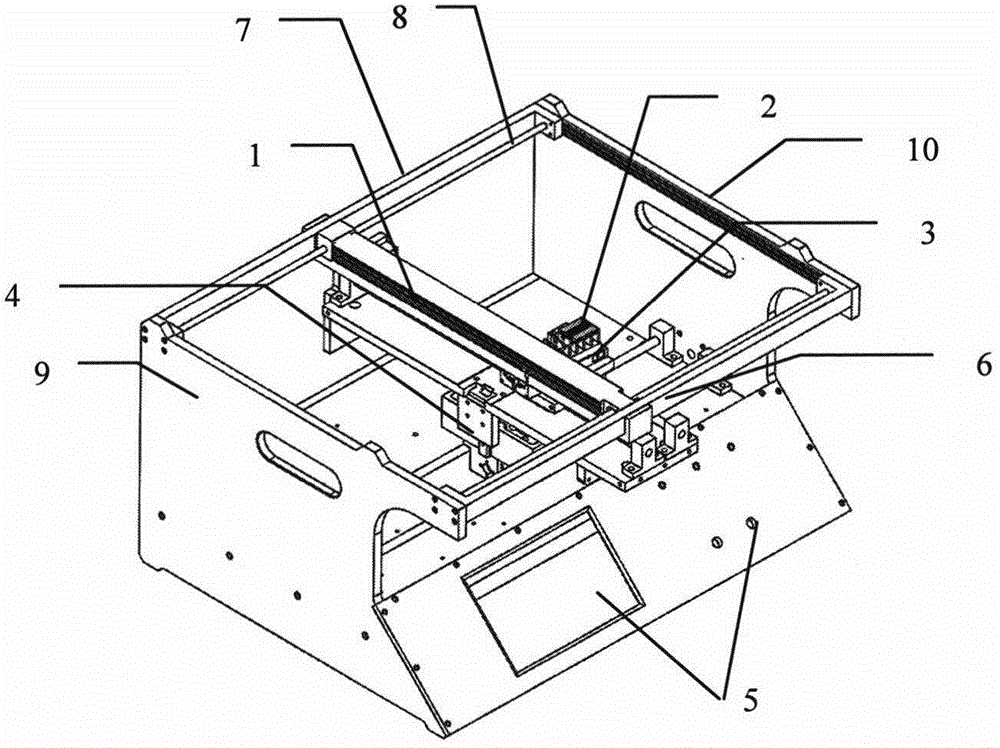

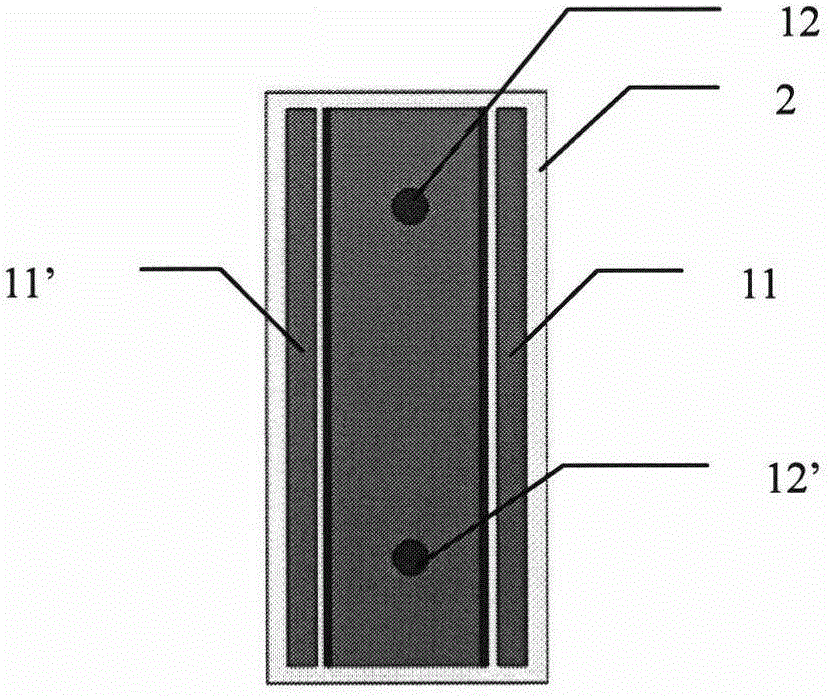

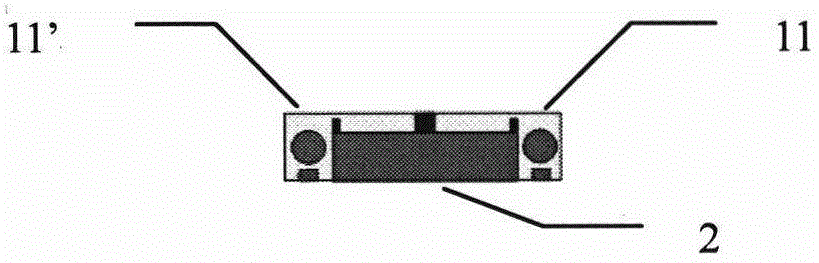

[0015] The schematic diagram of the structure of the dual in-line package chip removal device (hereinafter referred to as the removal device) is as follows figure 1 As shown, it includes a circuit board fixing unit 1 , a tin bath unit 2 , a heating temperature control unit 3 , a positioning unit 4 , an operation display unit 5 and frames 6 , 7 , 9 , and 10 .

[0016] Wherein, the circuit board fixing unit 1 is positioned at the top of the dismounting device, one end of which is vertically connected to the front frame 6 of the dismounting device, and the other end is vertically connected to the cylindrical cross bar 8 on the rear frame 7 which is horizontal to the front frame 6, along the The circuit board fixing unit 1 can be pushed along the vertical direction of the circuit board fixing unit 1 . There are three grooves matching the thickness of the circuit board on the left and right sides of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com