Wrapping assembly device

An assembly device and wrapping technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of visual impairment of staff, slow manual assembly speed, and long time-consuming, so as to achieve fast acceleration and improve assembly efficiency , the effect of reducing the labor force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

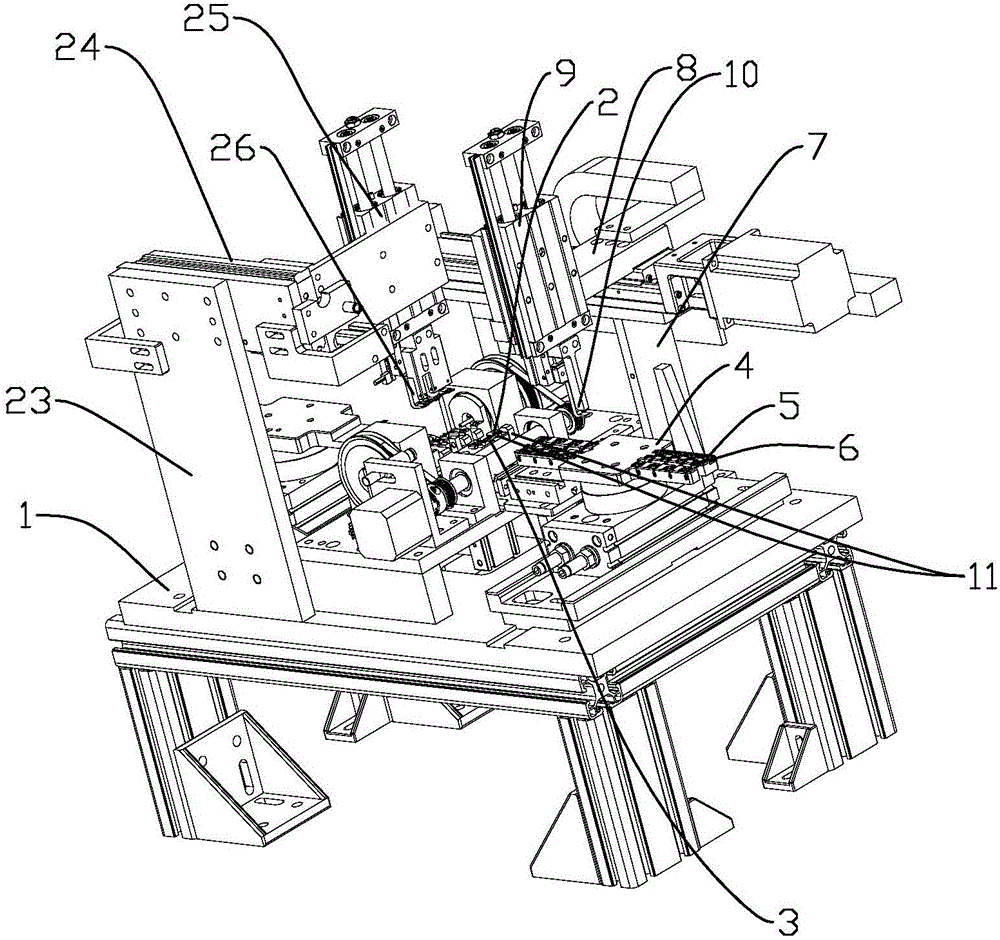

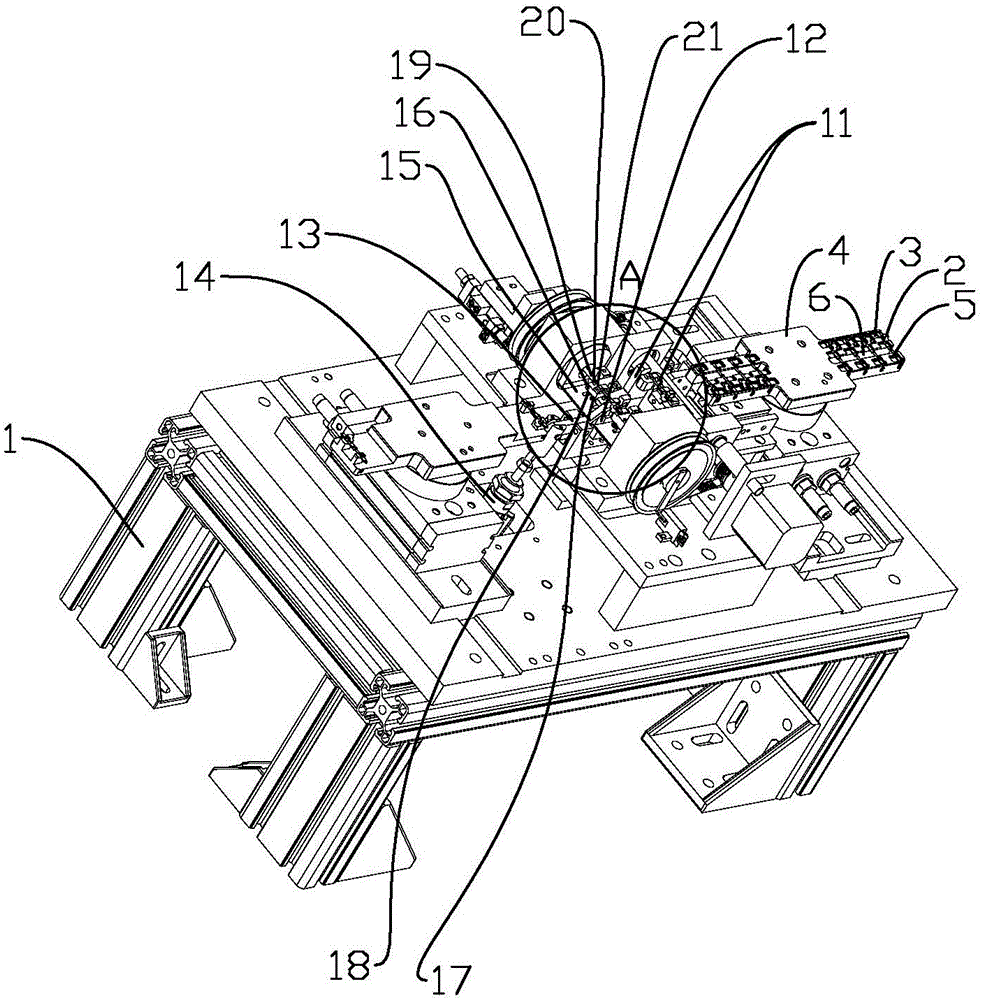

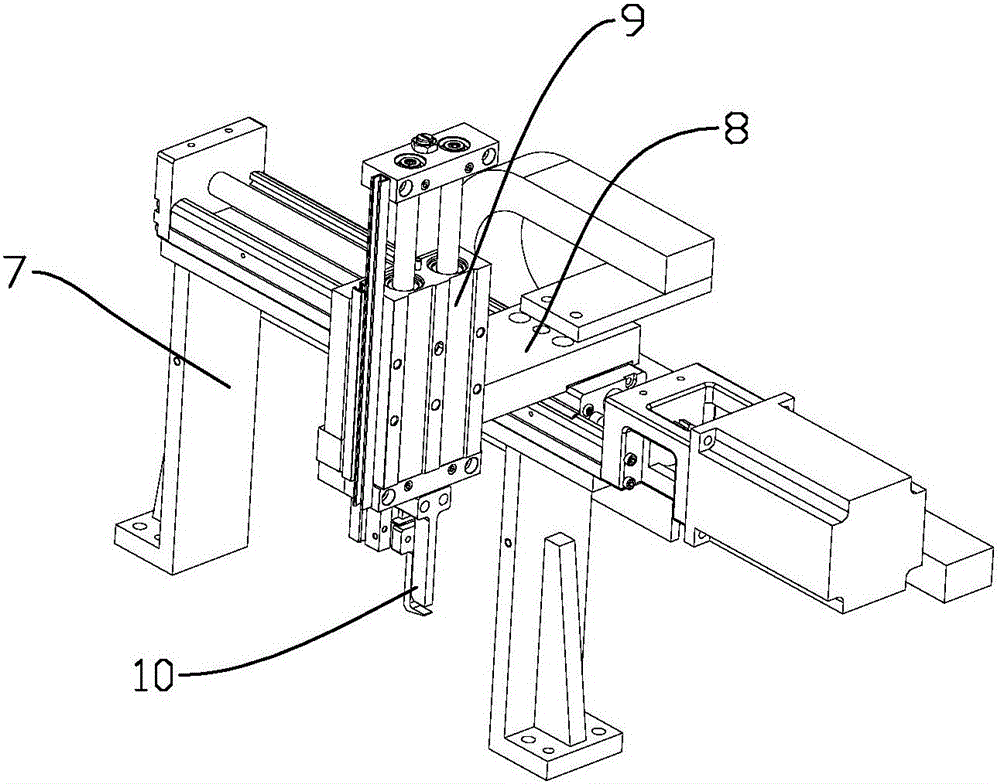

[0030] refer to Figure 1 ~ Figure 3 , the present invention is a wrapping assembly device, comprising: a frame 1; a raw material placement mechanism, installed on the frame 1, for arranging and placing products 3 to be wrapped; a feeding mechanism, installed on the frame 1, It is used to move the product 3 to be wrapped to the set position; the positioning mechanism is installed on the frame 1, and is used for secondary positioning of the product 3 to be wrapped, and the feeding mechanism moves the product 3 to be wrapped from the raw material placement mechanism to The positioning mechanism; the wrapping mechanism, installed on the frame 1, is used to wrap the product 3 to be wrapped, and the feeding mechanism moves the product 3 to be wrapped from the positioning mechanism to the wrapping mechanism; the unloading mechanism is installed on On rack 1, it is used to remove the wrapped finished product from the wrapping mechanism. The present invention adopting the above-menti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com