Panel Adhesive and How to Use It

A back glue and panel technology, applied in the direction of chemical instruments and methods, lamination, lamination auxiliary operations, etc., can solve the problems of prolonged working hours, troublesome tearing of the release film, difficult positioning, etc., to achieve convenient tearing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

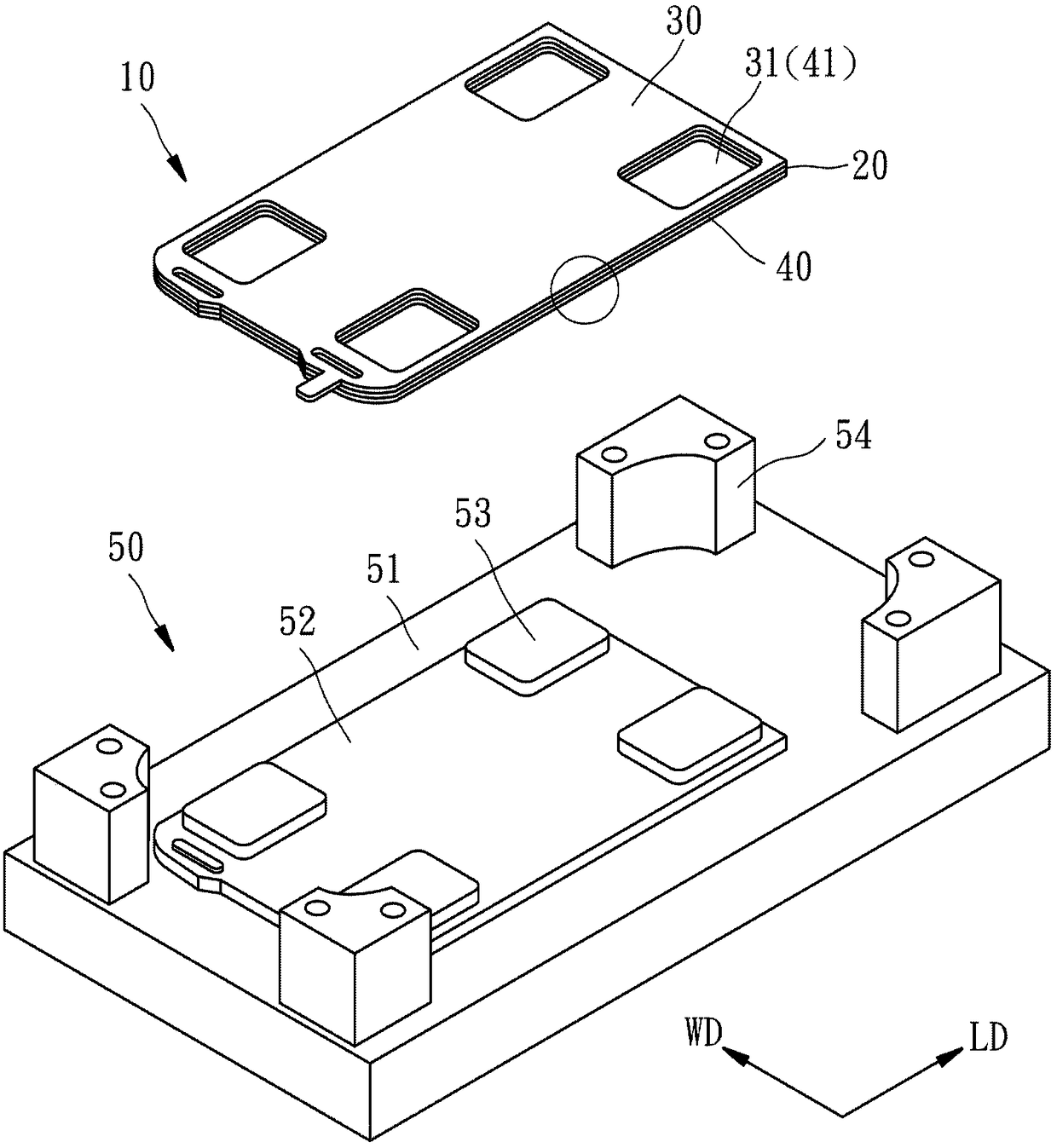

[0037] In order to clearly illustrate the features of the present invention, the panel adhesive 10 of a preferred embodiment provided by the present invention, as figure 1 As shown, it can be used with a clamp 50 . It should be added that the following embodiments are described with the panel adhesive 10 directly above the jig 50 as the use direction, and the release films 30 and 40 of the panel adhesive 10 define the longitudinal direction LD and the width direction WD.

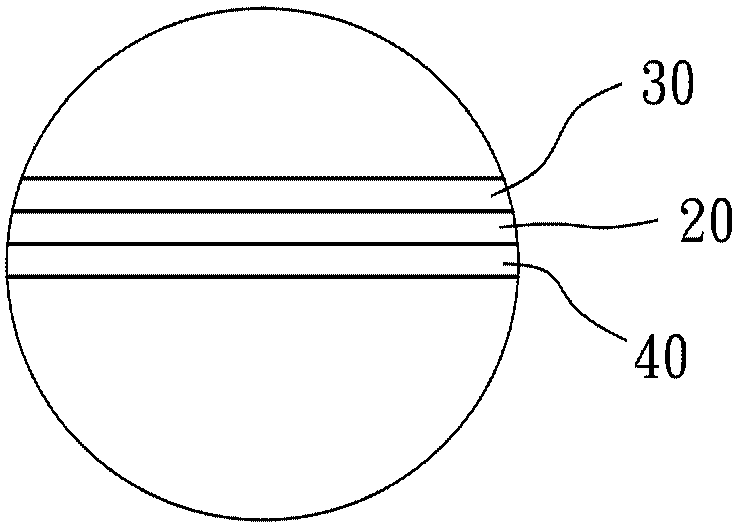

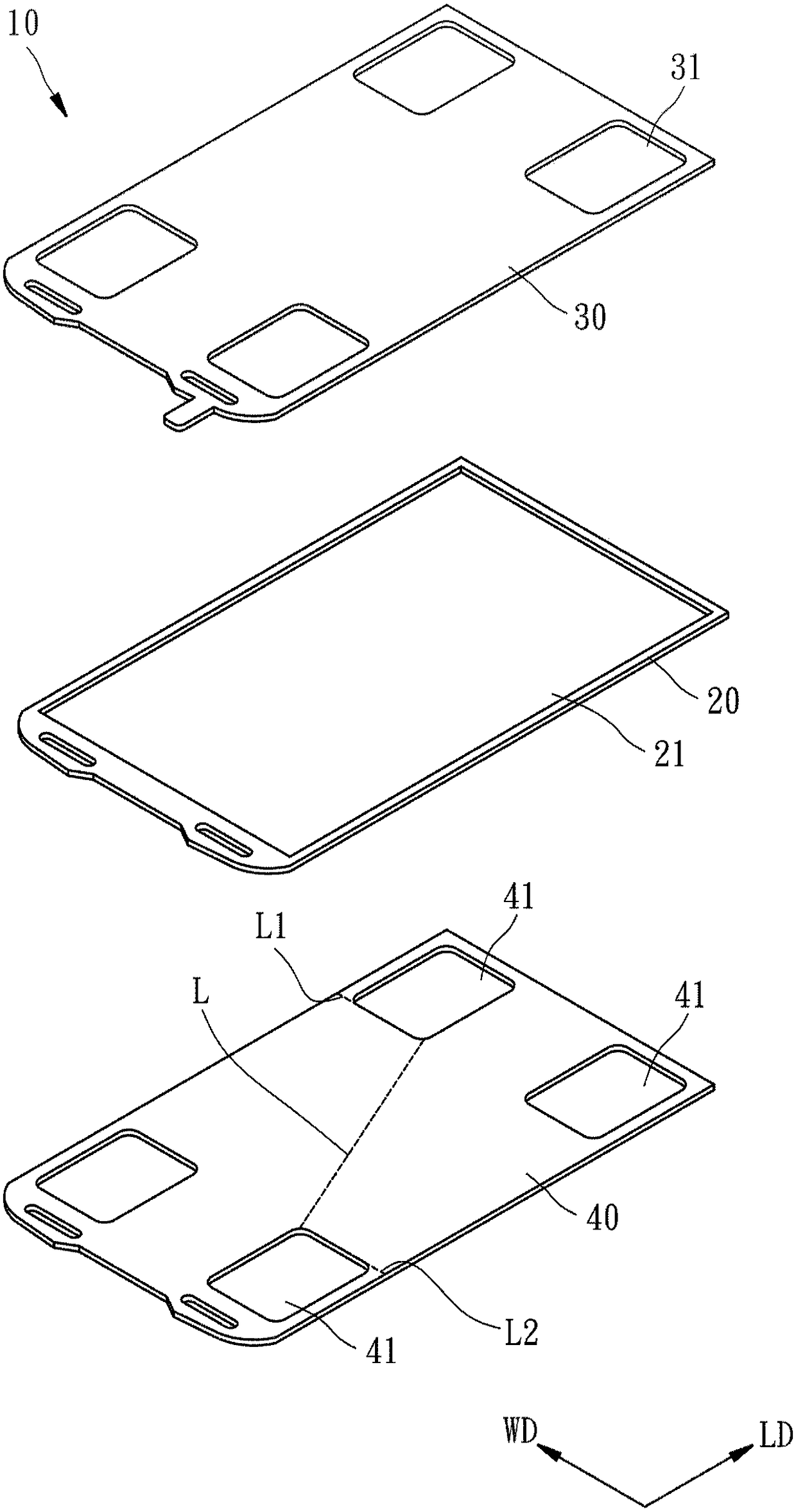

[0038] Please refer to image 3 , the panel adhesive 10 is roughly quadrangular and has colloid 20 and two layers of release film 30, 40. The colloid 20 is in the shape of a rectangular frame and has an opening 21 inside. The release film 30, 40 is also quadrilateral and the above opening 21 The covered state is pasted on the opposite two sides of the colloid 20 respectively, and four square positioning holes 31,41 are respectively provided on the release film 30,40, and the four positioning holes 31,41 are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com