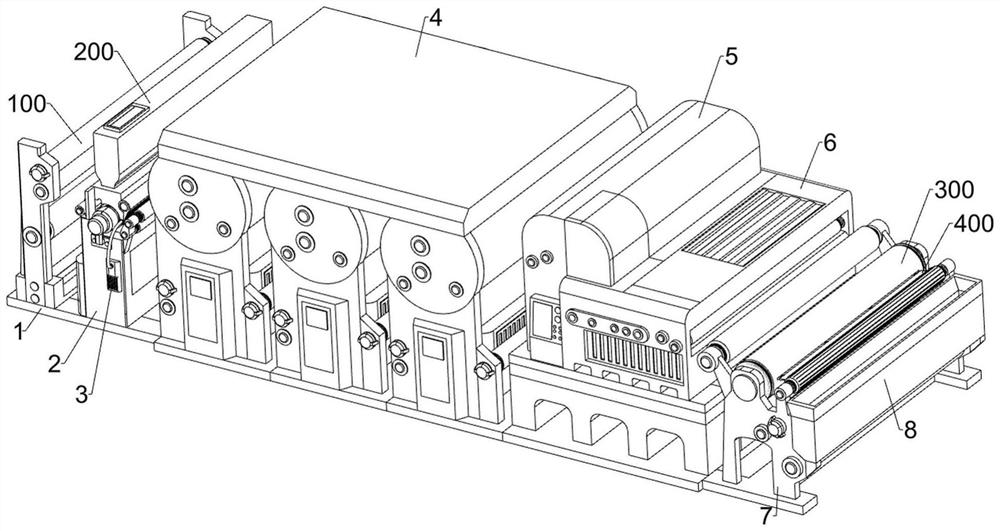

Surface multi-resistance decorative paper intaglio printing process and equipment

A gravure printing process and gravure printing technology, applied in printing, printing machines, rotary printing machines, etc., can solve the problems of small deformation error and low production cost, and achieve the effects of reducing production costs, reducing usage, and improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

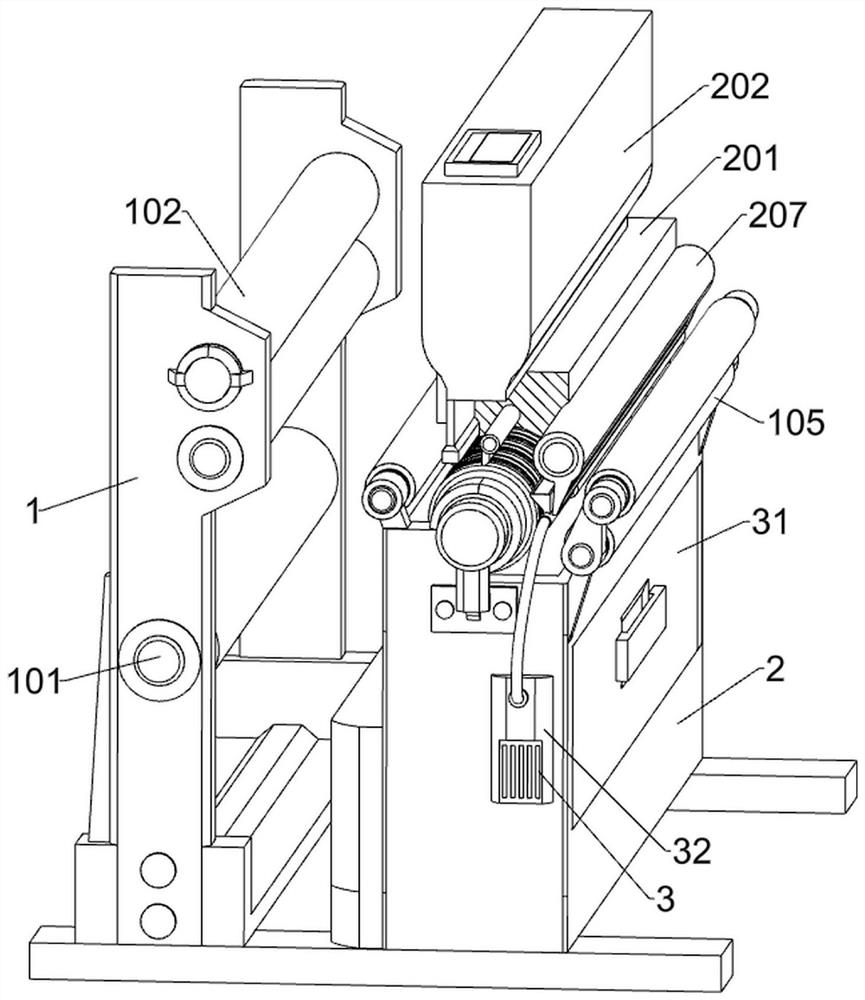

[0047] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but it is not used as a basis for limiting the present invention.

[0048] Surface multi-resistant decorative paper gravure printing process, comprising the following steps,

[0049] (S01) Silica gel liquid synthesis

[0050] Take an appropriate amount of olefinic silicone oil, silicone oil, crosslinking agent, catalyst and curing agent, put it into the feeding cabin, stir and mix to obtain silicone liquid; the mass ratio of olefinic silicone oil, silicone oil, crosslinking agent, catalyst and curing agent is 22~28:1:27~32:0.07~0.12:0.16~0.23; more preferably, the mass ratio of olefin silicone oil, silicone oil, crosslinking agent, catalyst and curing agent is 25:1:30:0.1:0.2 .

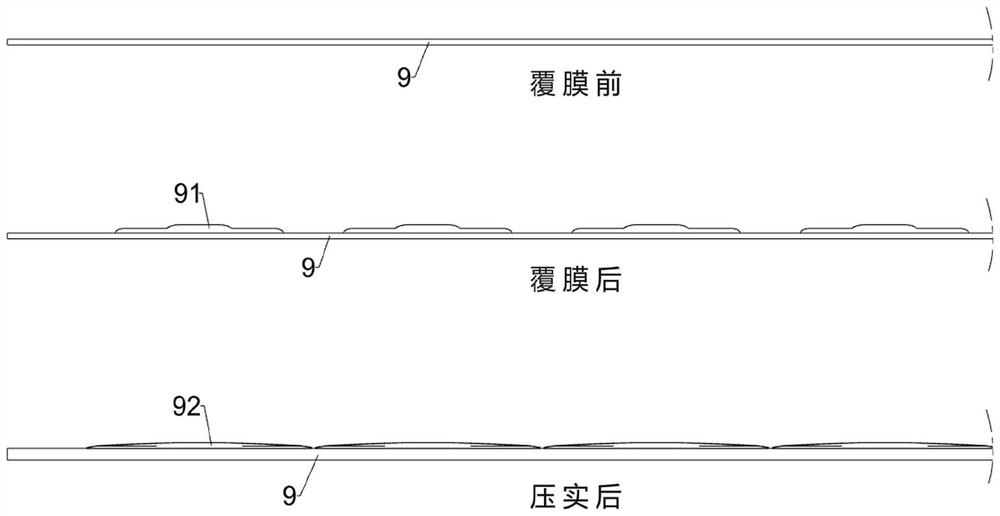

[0051] (S02) Silicone liquid paste

[0052] Get the decorative paper substrate, apply the silicone solution in the step (S01) on the back of the decorative paper substrate to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com