Film tearing mechanism for a film material

A technology of film material and film head, which is applied in the field of film material tearing mechanism, can solve the problems of difficult to tear off the release film, low assembly efficiency, no handle, etc., and achieve the effect of ensuring normal assembly operation and assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

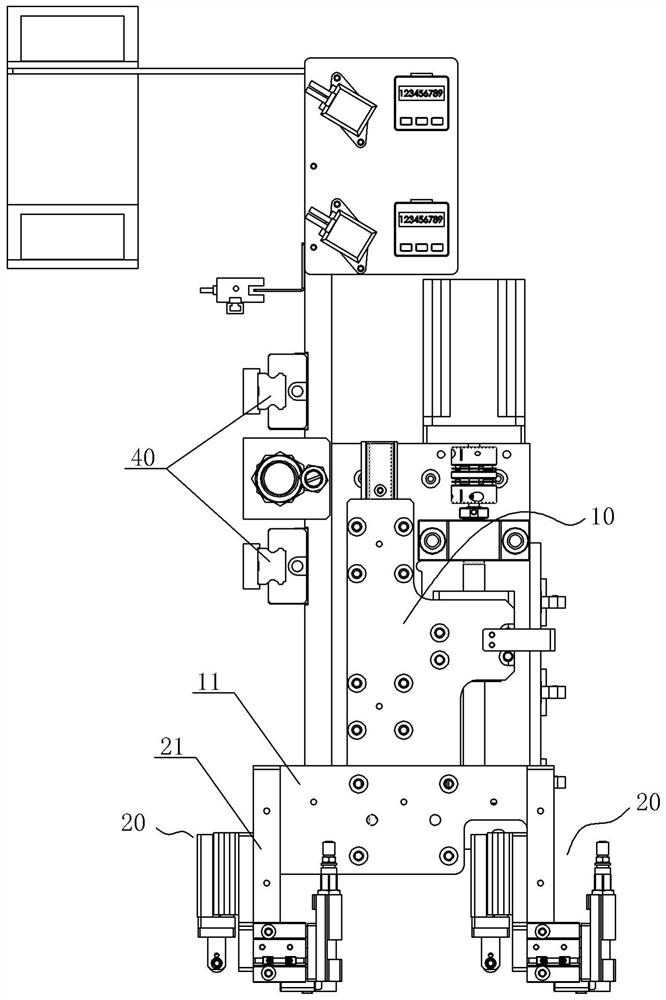

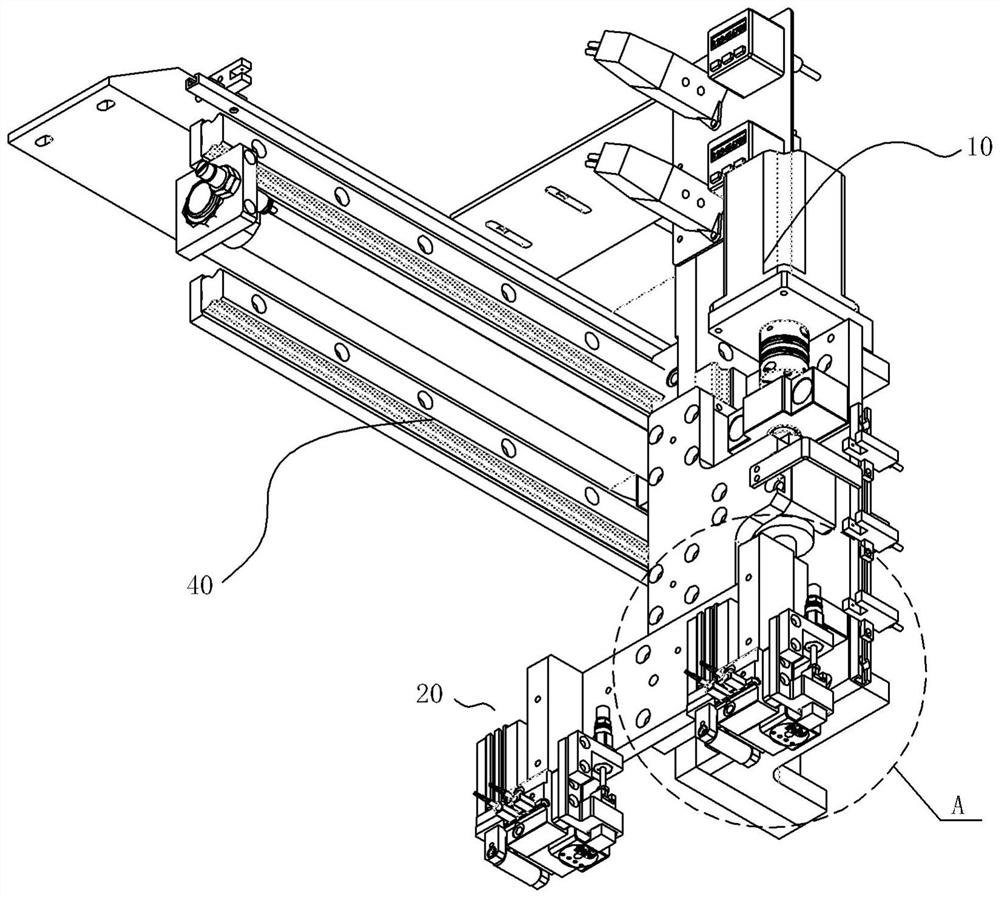

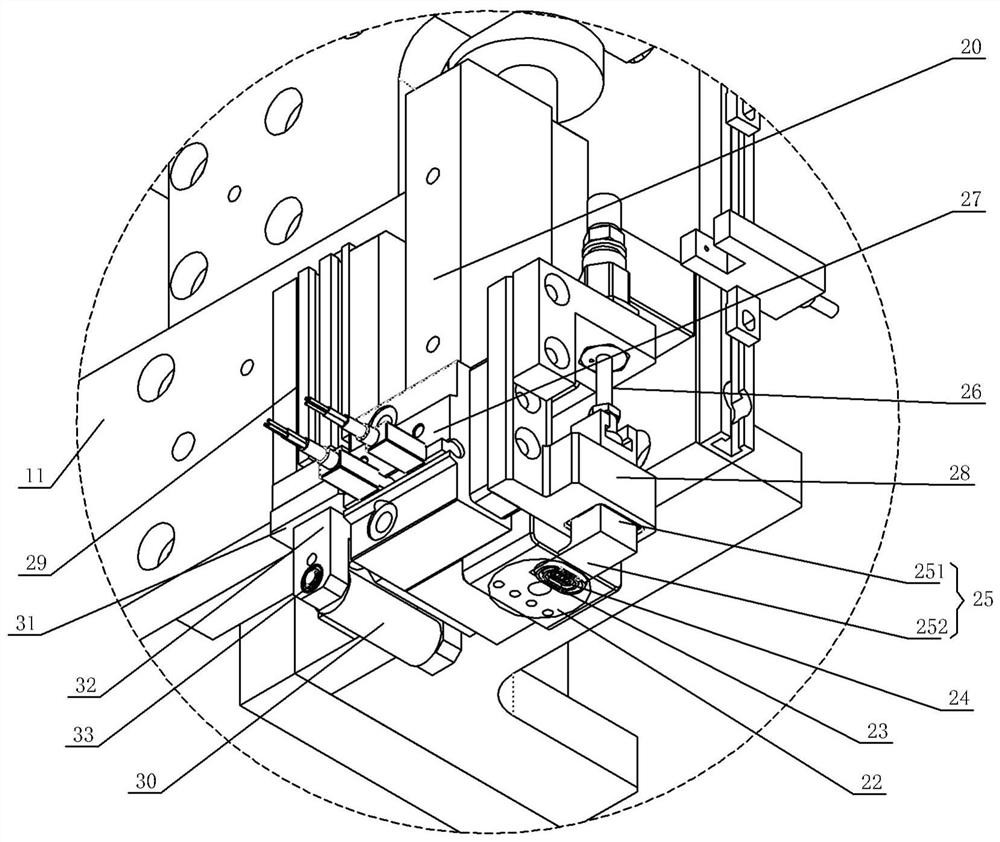

[0027] Specific examples, see Figure 1-Figure 3 The first vertical movement structure is specifically a pen-shaped cylinder 26; the first horizontal movement structure is specifically a double-connected cylinder 27; a side output end of the double-connected cylinder 27 is provided with a pen-shaped cylinder connecting frame 28, and the pen-shaped cylinder 26 is fixed on the pen-shaped cylinder to connect Frame 28, the lower output end of pen-shaped cylinder connecting frame 28 is fixedly equipped with the upper knife seat 251 of peeling knife 25;

[0028] The output end on the other side of the double-connected cylinder 27 is fixedly connected with a vertical sliding table cylinder 29, and the lower output end of the vertical sliding table cylinder 29 is connected with a rubber roller 30, which is used for film alignment after the release film is removed. Surface smoothing and pressing treatment;

[0029] The rubber roller installation frame 31 is connected to the lower outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com