Preparation method of pressure-sensitive adhesive tape for blocking ultrasonic probe

A pressure-sensitive tape, ultrasonic probe technology, applied in pressure-sensitive films/sheets, adhesives, film/sheet-like adhesives, etc. Clear, easy-to-use, quick-to-replace effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Preparation of acrylate copolymer glue: first add 294.3 g of solvent ethyl acetate to a 1L four-necked flask, and then add reaction monomers in sequence according to the reaction ratio: acrylic acid (AA) 6 g, butyl acrylate (BA) 172.8g, isooctyl acrylate (EHA) 41.4g, vinyl acetate (VAc) 54g, stir evenly and heat up in a water bath. When the temperature in the flask rises to about 80-82°C, dissolve 0.72g of benzoyl peroxide in 21g of ethyl acetate, and then dropwise add it into a four-necked flask to initiate a polymerization reaction, wherein the dropping time is 1h, dropwise After adding, carry out insulation 1h subsequently; After insulation finishes, start dripping initiator solution again, wherein initiator solution is the ethyl acetate that the benzoyl peroxide of 0.36g is dissolved in 10.8g, the time of dropping is 20min, insulation The time is 40min; after the heat preservation is finished, add the initiator solution dropwise again at last, wherein the initia...

Embodiment 2

[0032] (1) Preparation of acrylate copolymer glue: first add solvent ethyl acetate 279.6g and isopropanol 14.7g to a 1L four-necked flask, then add reaction monomers in sequence according to the reaction ratio: acrylic acid (AA) 6g, Butyl acrylate (BA) 172.8g, isooctyl acrylate (EHA) 41.4g, vinyl acetate (VAc) 54g, stir evenly and heat up in a water bath. When the temperature in the flask rises to about 80-82°C, dissolve 0.72g of benzoyl peroxide in 21g of ethyl acetate, and then dropwise add it into a four-necked flask to initiate a polymerization reaction, wherein the dropping time is 1h, dropwise After adding, carry out insulation 1h subsequently; After insulation finishes, start dripping initiator solution again, wherein initiator solution is the ethyl acetate that the benzoyl peroxide of 0.36g is dissolved in 10.8g, the time of dropping is 20min, insulation The time is 40min; after the heat preservation is finished, add the initiator solution dropwise again at last, where...

Embodiment 3

[0038] (1) The preparation of the acrylate copolymer glue is the same as in the examples.

[0039] (2) Preparation of pressure-sensitive adhesive tape: Take 21g of glue A and 9g of glue B to obtain a mixed glue, then add 1.29mg of aluminum acetylacetonate, stir evenly, use a spreader to sizing on the polyethylene substrate, and the thickness of the sizing is 50 μm, and finally placed in an oven and cured at 100°C for 15 minutes to obtain a pressure-sensitive adhesive tape.

[0040] The pressure-sensitive adhesive tape prepared above is subjected to a performance test: the initial adhesion force is a No. 4 ball, and the 180° peeling force is 4.83N·25mm -1 (there is residual glue on the steel plate), the holding force is 2.75h.

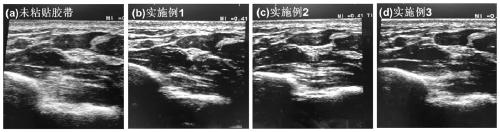

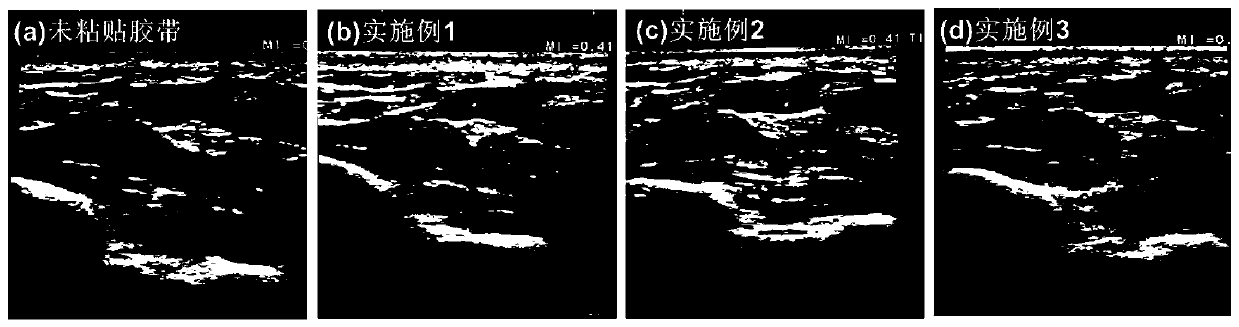

[0041] The pressure-sensitive adhesive tape prepared above was applied to a medical ultrasonic instrument to observe its image clarity. compared to figure 1 (a), it can be seen that the image definition in embodiment 3 is also relatively clear, as fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com