A treatment towel production system

A technology of production system and treatment towel, applied in medical science, surgery, surgical drape, etc., can solve the problem of high risk of foreign body bacteria, save precious time and reduce manpower configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation of the present invention will be further described below in conjunction with the examples.

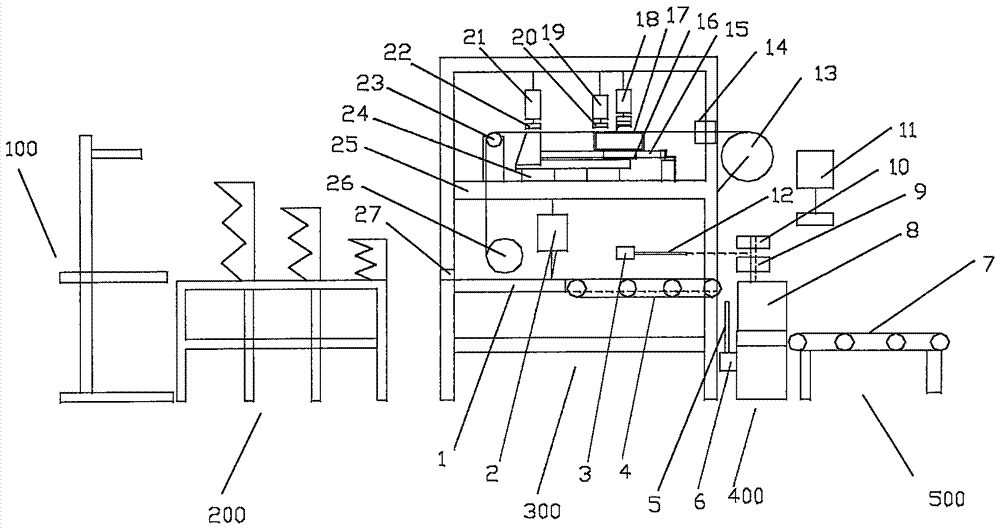

[0023] Such as figure 1 As shown, a treatment towel production system includes a feeding rack for placing rolls of cloth, a four-layer folding mechanism, a gripping system, a two-stage folding device, and a treatment towel receiving device. The whole roll of cloth is composed of a four-layer folding mechanism After folding, it is folded by the glue grip system and the two-stage folding device to form a treatment towel, which is collected by the treatment towel receiving device and transported to the next process.

[0024] The glue-holding system includes a frame on which a tape roller and a sensor 1 for detecting the number of revolutions of the tape roller are arranged, and an upper bracket and a lower bracket are arranged in the frame.

[0025] Among them, the upper bracket is provided with a rubber feeding roller, a fixed block, and a guide rail. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com