Manufacturing process of coal amber decoration painting

A technology for making crafts and decorative paintings, which is applied in decorative arts, special decorative structures, etc., and can solve problems such as high labor costs, long production time, and unsuitability for mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0046] The present invention provides a kind of manufacture craft of making coal amber decorative painting, it is characterized in that, comprises the following steps:

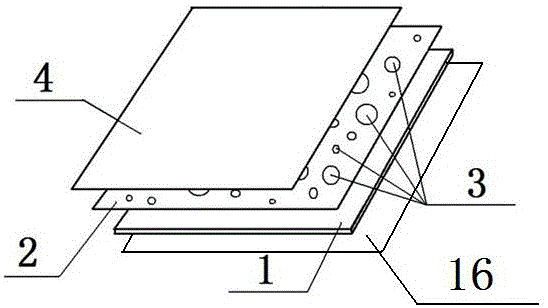

[0047] laying pictures (16) under the transparent substrate (1);

[0048] Use a painting tool to dip the adhesive on the transparent substrate (1) to trace the picture (16) laid under the transparent substrate to form a bonding layer (2);

[0049] Coal or amber or coal and amber or shale or shale and amber or shale and coal or shale and amber and coal or coal complex or amber complex or shale complex or coal amber complex or coal shale The composite body or the amber shale composite body or the coal amber shale composite body is arranged on a transparent substrate (1) provided with an adhesive layer (2), and bonded and fixed with the adhesive layer to form a patterned layer (3);

[0050] Withdraw the picture under the transparent substrate and clean up excess coal or amber or coal and amber or shale or shale ...

Embodiment 2

[0055] laying pictures (16) under the transparent substrate (1);

[0056] Use a painting tool to dip the adhesive on the transparent substrate (1) to trace the picture (16) laid under the transparent substrate to form a bonding layer (2);

[0057] disposing coal particles on a transparent base material (1) provided with an adhesive layer (2), and bonding and fixing the adhesive layer with the adhesive layer to form a patterned layer (3);

[0058] Remove the picture under the transparent substrate, and clean up the excess coal particles and dust except for the composition layer bonded to the transparent substrate through the adhesive layer, and repair the composition layer (3);

[0059] Spraying a fixer liquid or an adhesive on the side of the transparent substrate on which the patterned layer is bonded to form a fixer layer (4);

[0060] Then glue the composition layer on the transparent base material and fix it after spraying the fixing layer, then repeatedly set the adhesiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com