Heavy Duty Truck

A truck, heavy-duty technology, applied in motor vehicles, trolleys, tracked vehicles, etc., can solve the problems of complex structure, large overall structure, and limited use of lifting devices, reducing time and labor costs, and improving The effect of carrying the weight of goods and meeting the needs of heavy loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

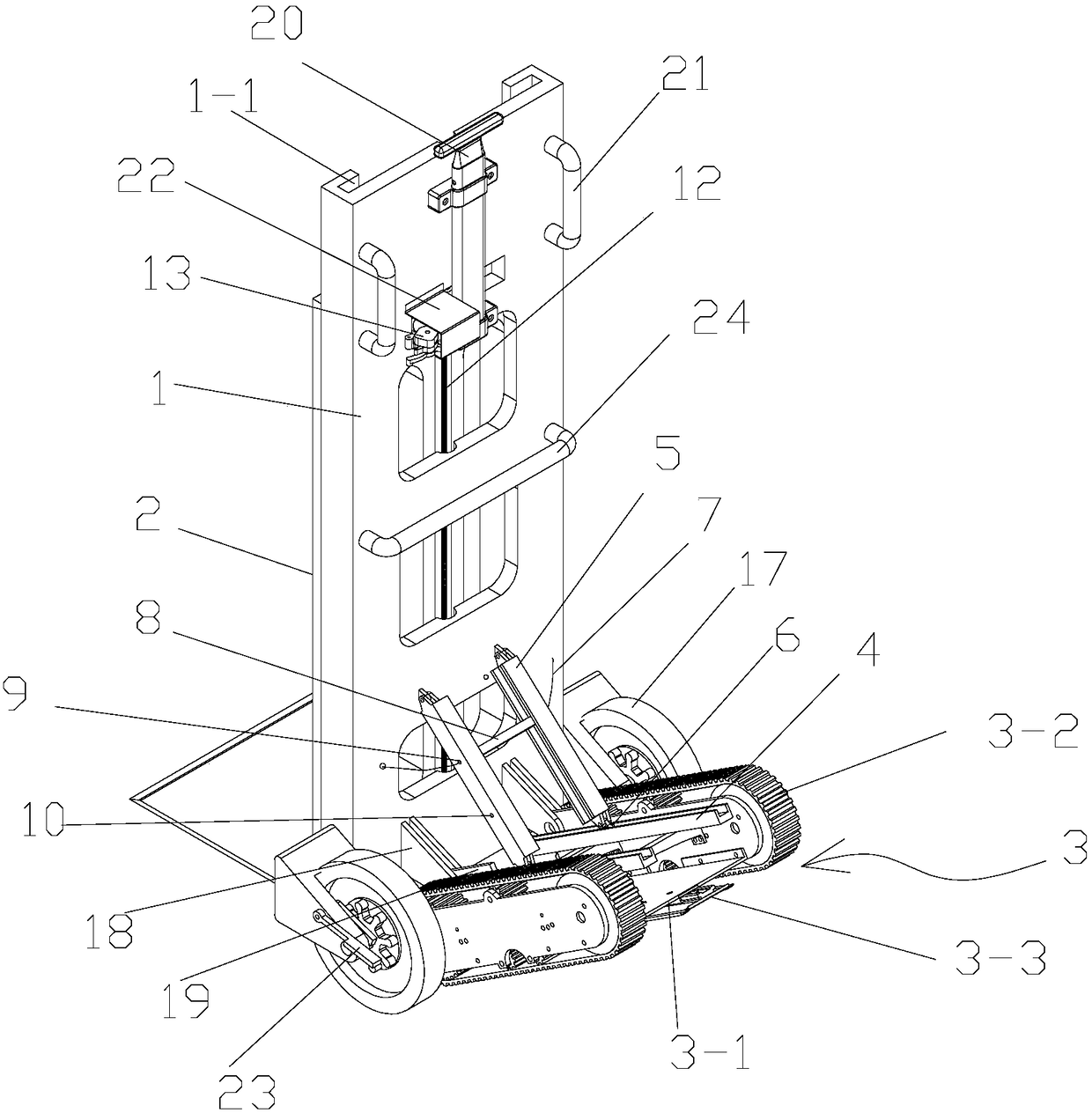

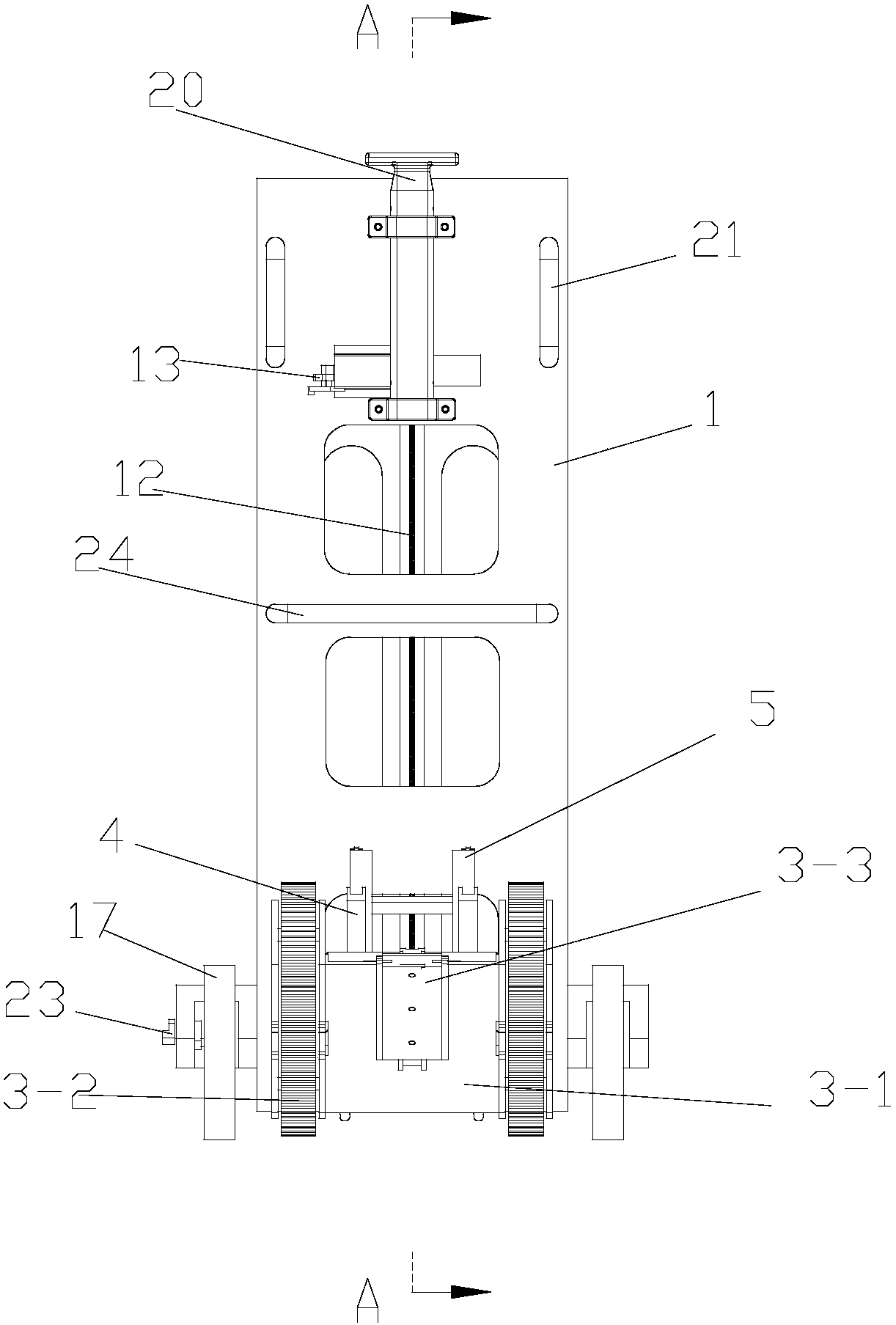

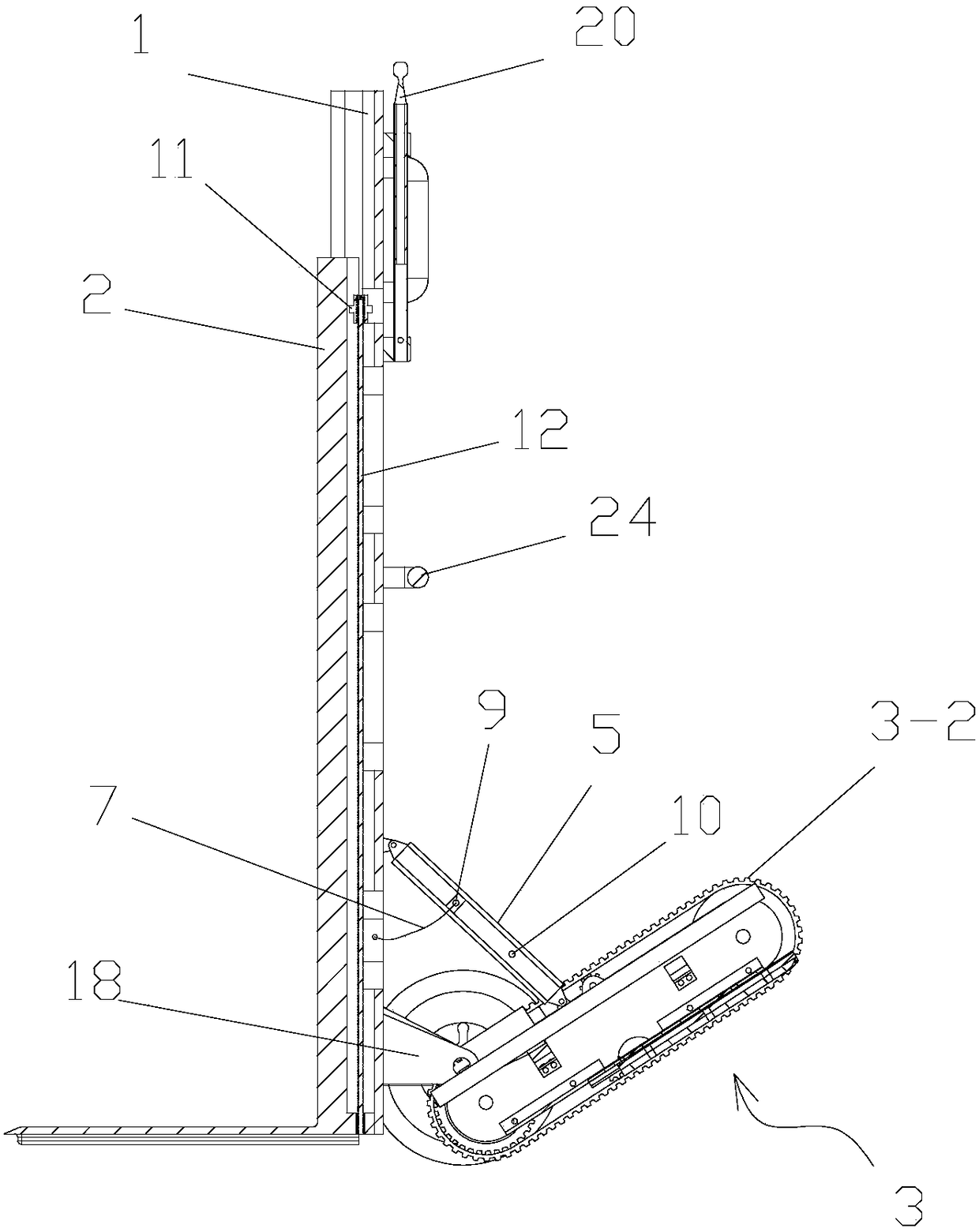

[0025] figure 1 It is a three-dimensional schematic diagram of the structure of the present invention, figure 2 It is a structural schematic diagram when the heavy-duty transport vehicle of the present invention is in the first gear, image 3 for figure 2 A-A direction view, Figure 4 for figure 2 top view, Figure 5 It is a structural schematic diagram when the heavy-duty transport vehicle of the present invention is in the second gear, Figure 6 It is a structural schematic diagram of the power walking device in the present invention, Figure 7 It is a structural schematic diagram of the brake mechanism in the present invention, as shown in the figure: the heavy-duty transport vehicle of this embodiment includes a vehicle frame 1, and a shelf 2 that is arranged in a relatively sliding manner with the vehicle frame 1 and is used to carry heavy objects And the power running device 3 that can be arranged in cooperation with the vehicle frame 1 in a manner that can rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com