A kind of profiling packaging device and packaging method thereof

A packaging bag and workbench technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of waste materials, difficult packaging, time-consuming and labor-intensive, etc., and achieve the effect of simplifying the working process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

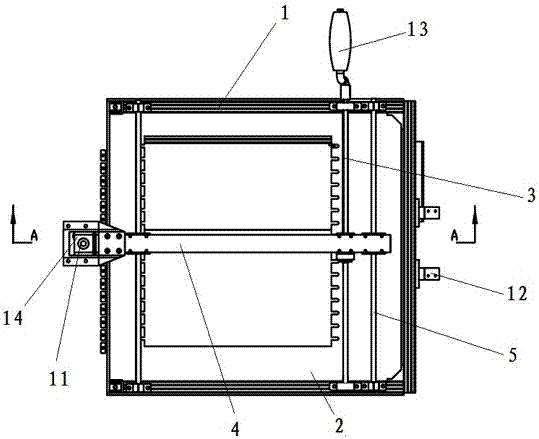

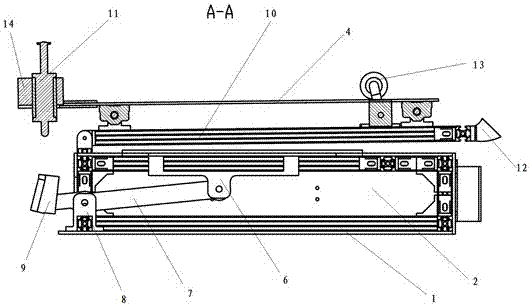

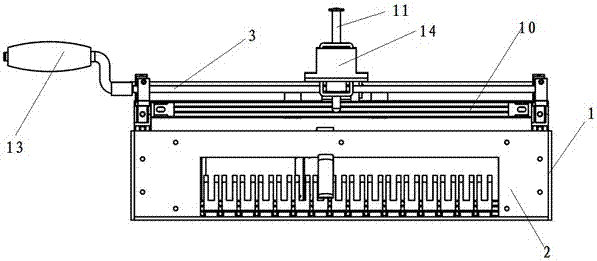

[0031] Such as Figure 1~4 As shown, the embodiment of the present invention provides a profiling packaging device, including a horizontal workbench 1, the middle part of the upper surface of the horizontal workbench 1 is opened inwardly with a cavity 2 for placing express delivery, and the upper end of the cavity 2 Several resistance wires are respectively arranged on the front side wall, the left side wall and the right side wall, and the resistance wires are respectively electrically connected to a control unit through a first time relay, and the horizontal workbench 1 is hinged with a A cutting mechanism for express packaging, the cutting mechanism is covered above the cavity 2; the cutting mechanism includes an outer frame 10 that is consistent with the size of the horizontal workbench 1, and an Screw mandrel 3 and the cutting bar 4 that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com