Non-uniform blanking method for aluminum electrolytic bath

An aluminum electrolytic cell and non-uniform technology, applied in the field of non-uniform feeding of aluminum electrolytic cells, can solve the problems of increasing the risk of early precipitation of alumina and increasing the area change of high-concentration areas, so as to optimize the distribution of alumina concentration and reduce the Concentration difference in a small area, promoting the effect of smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing, but the protection scope of the present invention is not limited by embodiment.

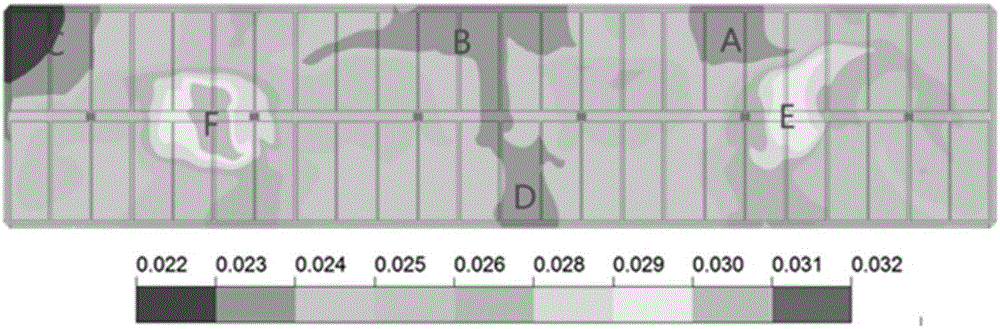

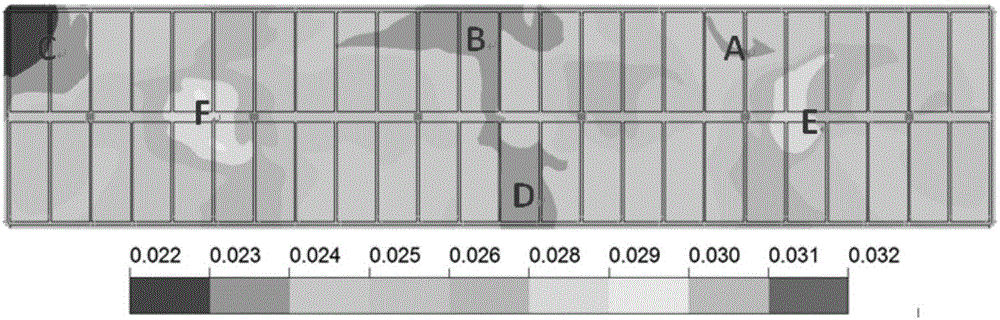

[0021] The non-uniform feeding method for aluminum electrolytic cell provided by the present invention selects the capacity of the constant container at each feeding point according to the characteristics of the electrolyte flow form and the distribution of alumina concentration in the cell, and uses the simulation method to compare the configuration of the obtained constant container Evaluation to determine the appropriate non-uniform fixed container configuration; at the same time, according to the selected fixed container capacity, adjust the feeding interval to ensure that the total feeding amount of the electrolytic cell remains unchanged within a certain period of time. The capacity of the fixed container is one or more of 0.8kg, 1.0kg, 1.2kg, 1.6kg, 1.8kg and 2.0kg. The simulation method ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com