Waterproof auxiliary frame for buildings as well as machining and mounting methods of auxiliary frame

A technology for construction and auxiliary frames, which is applied in the direction of buildings, building components, building structures, etc. It can solve the problems of large deformation, strong thermal conductivity and leakage of metal auxiliary frames, and achieve excellent windproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

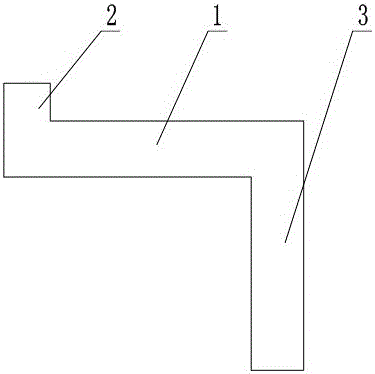

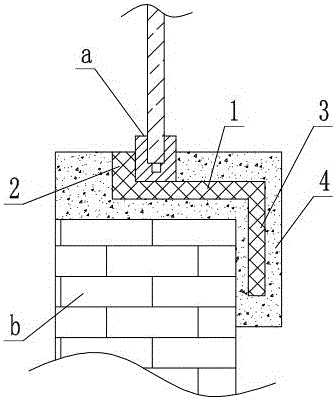

[0023] In embodiment one, if figure 1 , figure 2 As shown, it includes a backing plate 1 for positioning doors and windows, an inner baffle 2 close to the indoor side of the door and window, and an outer baffle 3 close to the outer wall of the hole; the inner baffle 2 covers the backing plate 1 and the The gap between doors and windows, the outer baffle plate 3 covers the gap between the backing plate 1 and the hole. Embodiment 1 The inner baffle plate 2 is used to block the gap between the backing plate 1 and the window a, and the outer baffle plate 3 is used to block the gap between the backing plate 1 and the opening wall b, effectively separating the indoor from the outdoor and preventing rainwater, etc. It leaks into the room from various gaps, and has excellent windproof, waterproof and anticorrosion properties.

[0024] In the first embodiment, if figure 1 As shown, the backing plate 1, the inner baffle 2 and the outer baffle 3 are integrally formed. The present in...

Embodiment 2

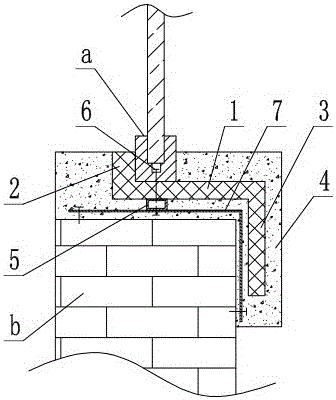

[0029] In the second embodiment, if image 3 , Figure 4 As shown, several anchors 5 are installed on the side of the backing plate 1 close to the hole, screws 6 for anchoring doors and windows are fixed on the top of the anchors 5, and a tie belt 7 is fixed below the anchors 5, so Said tie belt 7 is anchored in said cement mortar layer 4 . Compared with the structure of the embodiment 2, the installation of the auxiliary frame is more firm. The anchor piece 5 and the pull-joint 7 can be glued together, or can be connected with screws and iron nails. The window can be directly fixed on the anchor piece 5 with the screw 6, or the screw 6 and the window can be clamped together with a V-shaped clamp. Wherein the anchor piece 5 is preferably made of an aluminum alloy, and the tie strap 7 is preferably made of a metal material such as a steel strip.

[0030] In the second embodiment, the distance between two adjacent anchor pieces 5 is less than or equal to 50 cm. In the secon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com