Electrical insulation structure for Hall thruster air supply pipeline

A technology of Hall thruster and air supply pipeline, applied in thrust reverser, using plasma, machine/engine, etc., can solve problems such as insulation failure, and achieve the effects of good insulation performance, improved insulation strength, and long life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

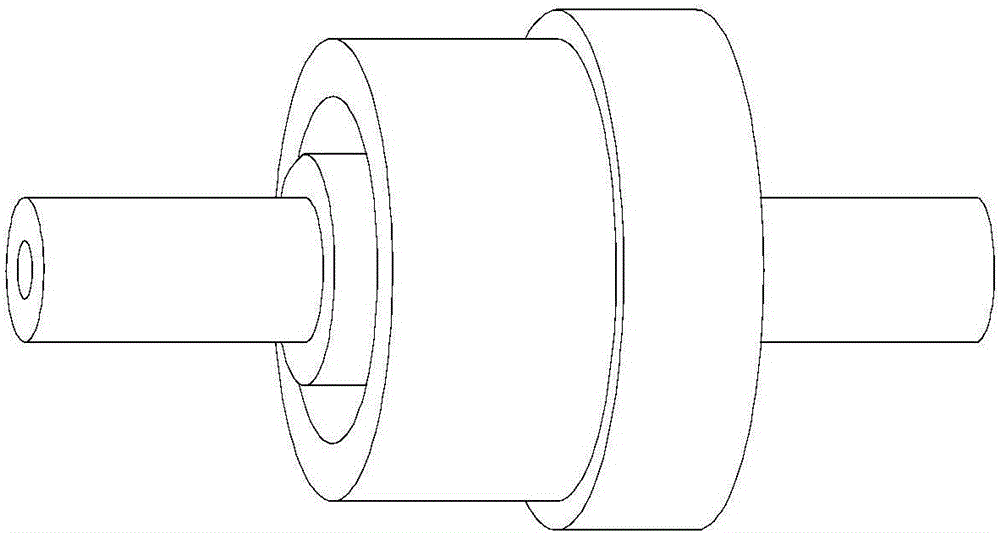

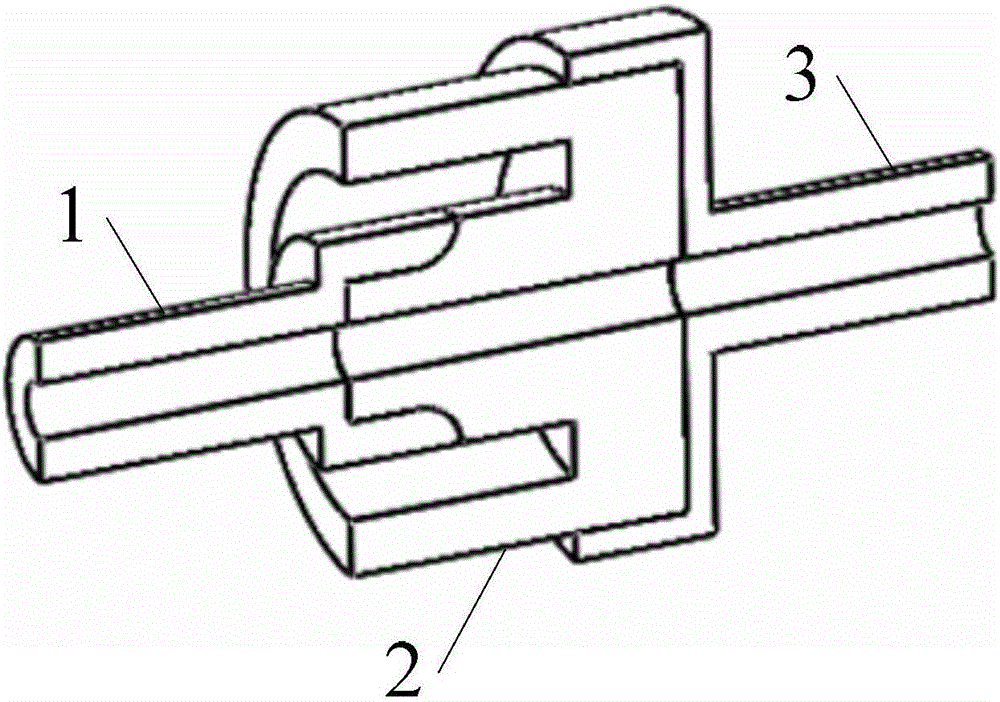

[0018] Specific implementation mode 1: refer to Figure 1 to Figure 4 To specifically describe this embodiment, the electrical insulation structure for the Hall thruster gas supply pipeline described in this embodiment includes a gas distributor pipeline 1, a ceramic insulator 2 and a metal port 3 for a storage and supply system.

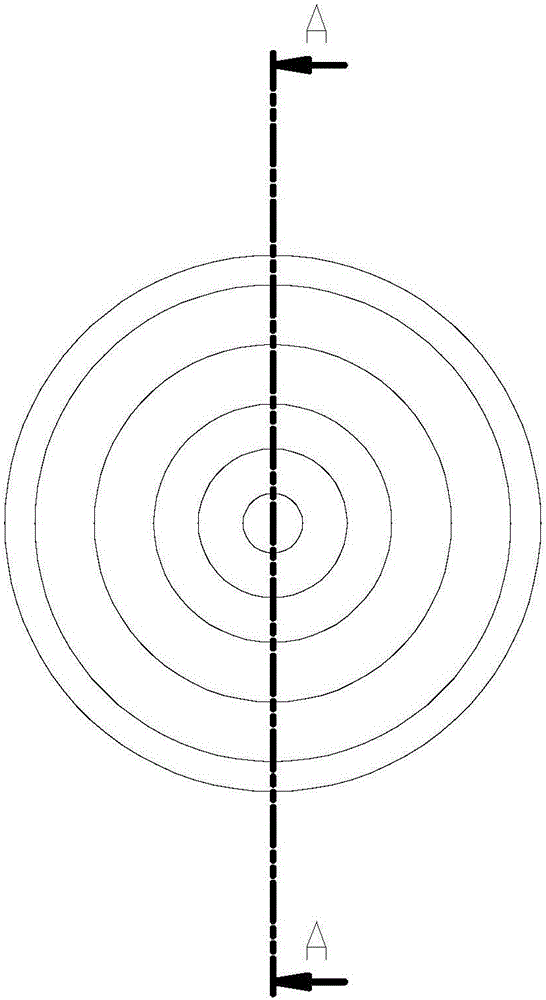

[0019] The cross section of the ceramic insulator 2 is a "mountain" type structure, and the outer surface of the ceramic insulator 2 is a cylindrical structure, and the middle end of the ceramic insulator 2 is a convex groove structure,

[0020] The metal port 3 of the storage and supply system is wrapped at the bottom of the ceramic insulator 2, the groove structure of the gas distributor pipeline 1 is connected with the convex groove structure of the ceramic insulator 2, and the ceramic insulator 2 wraps the gas distributor pipeline 1 inside,

[0021] The gas distributor pipeline 1, the ceramic insulator 2 and the inner cavity of the metal port 3 ...

specific Embodiment approach 2

[0027] Embodiment 2: This embodiment further describes the electrical insulation structure for the Hall thruster gas supply pipeline described in Embodiment 1. In this embodiment, the metal port 3 of the storage and supply system and the bottom of the ceramic insulator 2 Solder connections.

specific Embodiment approach 3

[0028] Embodiment 3: This embodiment further describes the electrical insulation structure for the Hall thruster gas supply pipeline described in Embodiment 1. In this embodiment, the middle end of the ceramic insulator 2 is connected to the gas distributor pipe. Way 1 solder connection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com