Wall hanging stove input hot water heat exchange system

A heat exchange system and wall-hung boiler technology, applied in the field of wall-hung boiler input hot water heat exchange system, can solve problems such as large limitations, and achieve the effect of reducing thermal pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

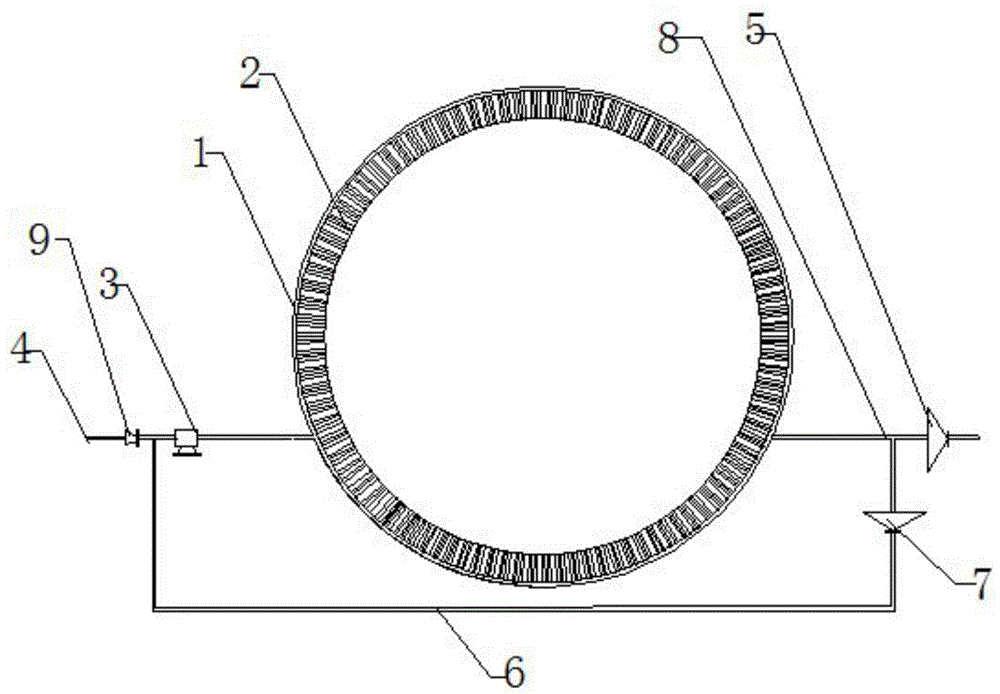

[0017] Such as figure 1 The shown wall-hung boiler input hot water heat exchange system includes a smoke outlet pipe (not shown), and a spiral metal tube 1 is wound on the inside of the smoke outlet pipe; a heat-absorbing fin is attached to the inside of the spiral metal tube 1 Group 2; the input end of the spiral metal pipe 1 is installed to the water inlet 4 through the water pump 3; the output end of the spiral metal pipe 1 is connected to the water inlet of the wall-hung boiler (not shown) through the first solenoid valve 5; the water inlet A circulation pipe 6 is installed between the input end of the water pump 3 and the input end of the first electromagnetic valve 5; a second electromagnetic valve 7 is installed on the circulation pipe 6; a third electromagnetic valve is installed between the water pump 3 and the water inlet 4. Valve 9.

[0018] Wherein, the spiral metal tube 1 is a thin-walled metal tube; the heat-absorbing fin group 2 is composed of a plurality of lo...

Embodiment 2

[0021] This embodiment is to transform the existing installed wall-hung boiler, and its specific structure is basically the same as that of Embodiment 1, wherein an external smoke pipe (not shown) is arranged on the outside of the spiral metal pipe 1; the external smoke pipe is installed At the smoke outlet of the smoke outlet pipe; other structures are consistent with the embodiments.

[0022] When installing, directly weld and fix the external smoke pipe and the smoke outlet pipe.

[0023] During work, turning on the water adding pump and the third electromagnetic valve is the water adding process, opening the water adding pump and the second electromagnetic valve is the circulation process, and opening the third electromagnetic valve is the wall-hung boiler water replenishing process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com