Self-propelled ship model test device applicable to arbitrary wave direction and application method for the same

A technology for testing and sailing ships, which is applied in the field of self-propelled ship model test and testing devices, can solve the problems of ship model yaw, affect the accuracy of test data, violate the self-propelled test method, etc., and achieve the effect of simplifying the test method and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

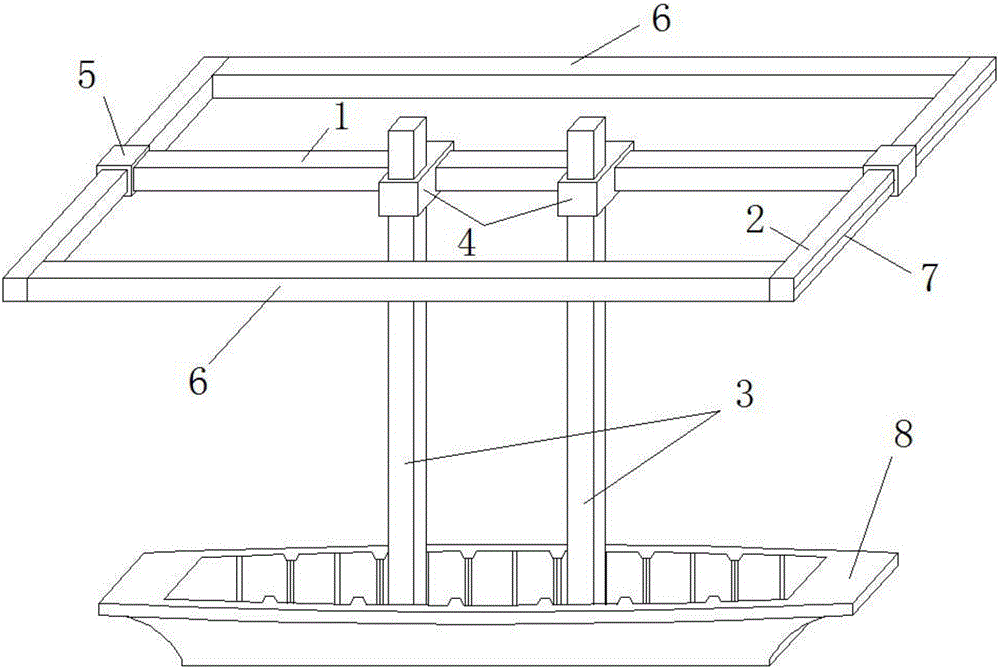

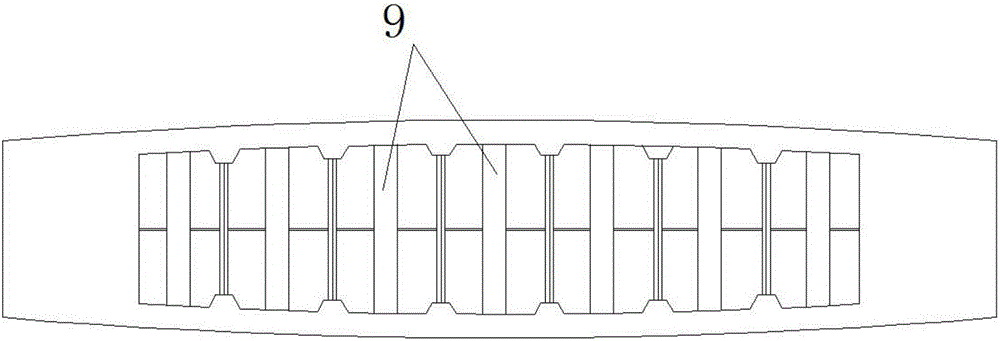

[0029] The self-propelled ship model test device applicable to any wave direction includes track I1, track II2, track III3, universal base 23 and elastic device 7, the universal base 23 is arranged at the bottom of track III3, and track III3 is arranged in parallel with There are two rails, and there are two rails Ⅱ2 in parallel. The rails Ⅰ1 and Ⅱ2 are vertical and in the same plane. The rail Ⅲ3 is perpendicular to the plane where the rails Ⅰ1 and Ⅱ2 are located. Located on the same side of the track I1, the two ends of the track I1 are connected to the two tracks II2 through a sliding device, and the two sides of the end of the track I1 are respectively equipped with elastic devices 7, one end of the elastic device 7 is connected to the end of the track I1, and the other end is connected to the end of the track I1. Track II2 connection.

[0030] Such as figure 1 As shown, the sliding device is a slider, and there is a slider II5 on the track II2, and the two ends of the tra...

Embodiment 2

[0044] In this embodiment, the difference from Embodiment 1 is that the relative sliding between the rails in Embodiment 1 is through sliders, that is, through sliding friction. In this embodiment, the sliding between rails is through rollers, that is, by means of rolling friction. When the track width is large and the contact surface between the slider and the track increases, the connection method of the slider will affect the test accuracy, and changing the sliding friction to rolling friction can solve the above problems well.

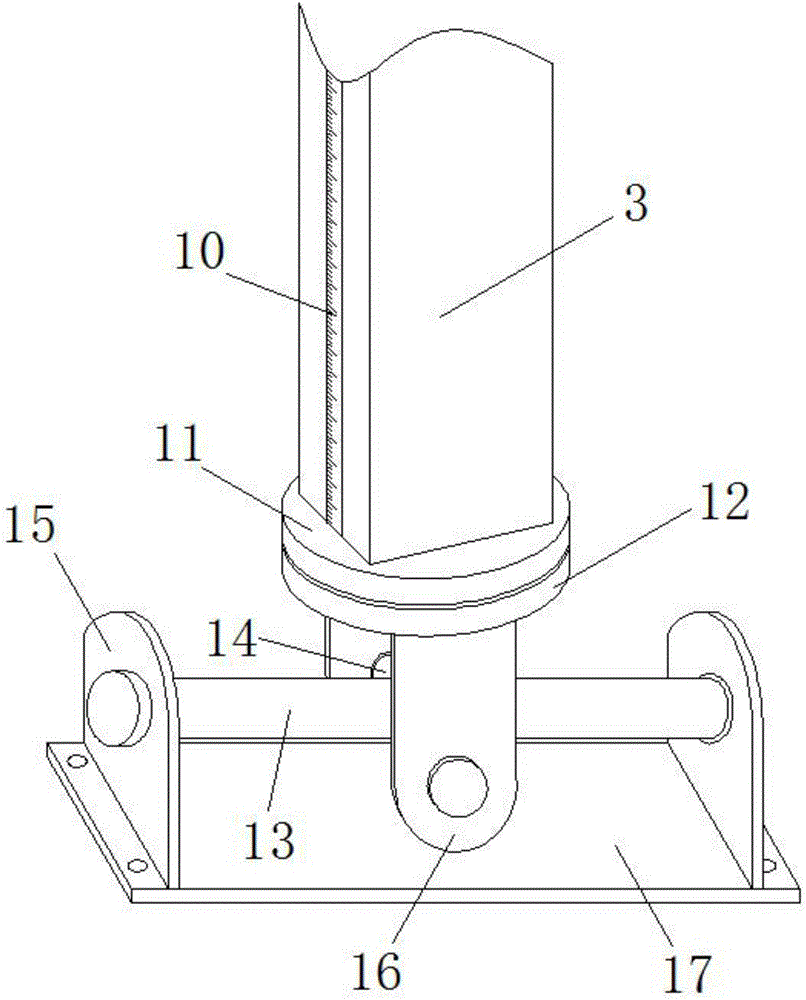

[0045] Such as Figure 5 to Figure 7 As shown, it is a preferred embodiment, the track I1 is provided with a sliding device I, the sliding device I includes a roller bracket II20 and rollers, the track III3 is provided with a sliding device III, and the sliding device III includes a roller bracket III and rollers, The roller bracket II20 is fixedly connected with the roller bracket III; the track II2 is provided with a sliding device II, the slidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com