Building material oxygen index test control system and control method and tester

The technology of a control system and control method is applied in the field of building material oxygen index test control system and test instrument, which can solve the problems of rough adjustment of oxygen concentration, inconvenient test time, long test time, and insufficient accuracy, etc., and achieve fast test speed, The effect of accurate test results and accurate measurement data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

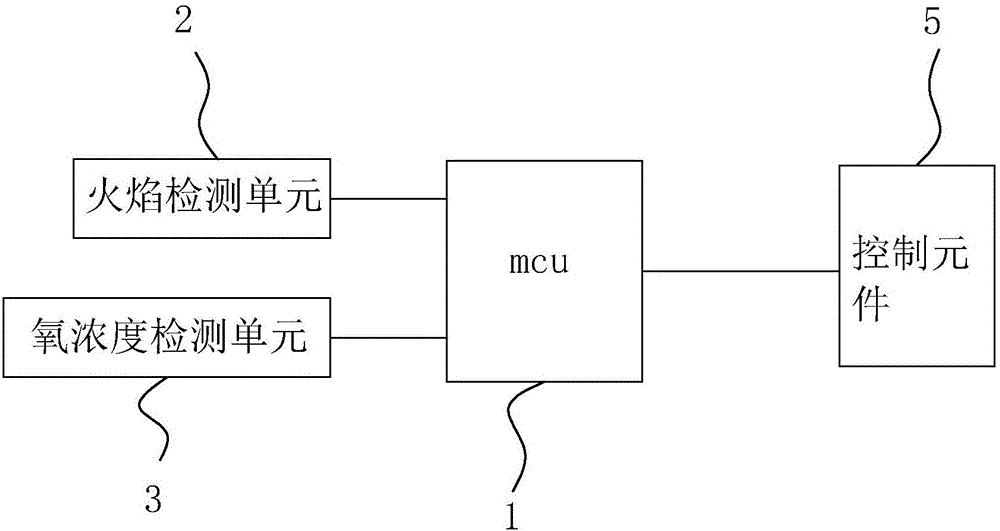

[0049] Embodiment one, see figure 1 As shown, a building material oxygen index test control system includes an oxygen concentration detection unit 3 , a flame detection unit 2 , a processing control unit 1 , and a control element 5 .

[0050] see Figure 4 , the oxygen concentration detection unit 3, the flame detection unit 2, the processing controller 1 and the control element 5 illustrate the logical relationship between the four, in order to illustrate the principle of the present embodiment, the oxygen concentration detection unit 3 is arranged on the oxygen index measuring instrument 8 The mixing pipeline inside is used to detect the oxygen concentration and output an oxygen concentration signal that is positively correlated with the oxygen concentration to the P1.1 access port of the AT89C51 microcontroller in the processing control unit 1. Whether the sample is burning, when the flame generated during combustion is detected, the timing signal is output to the P1.2 acc...

Embodiment 2

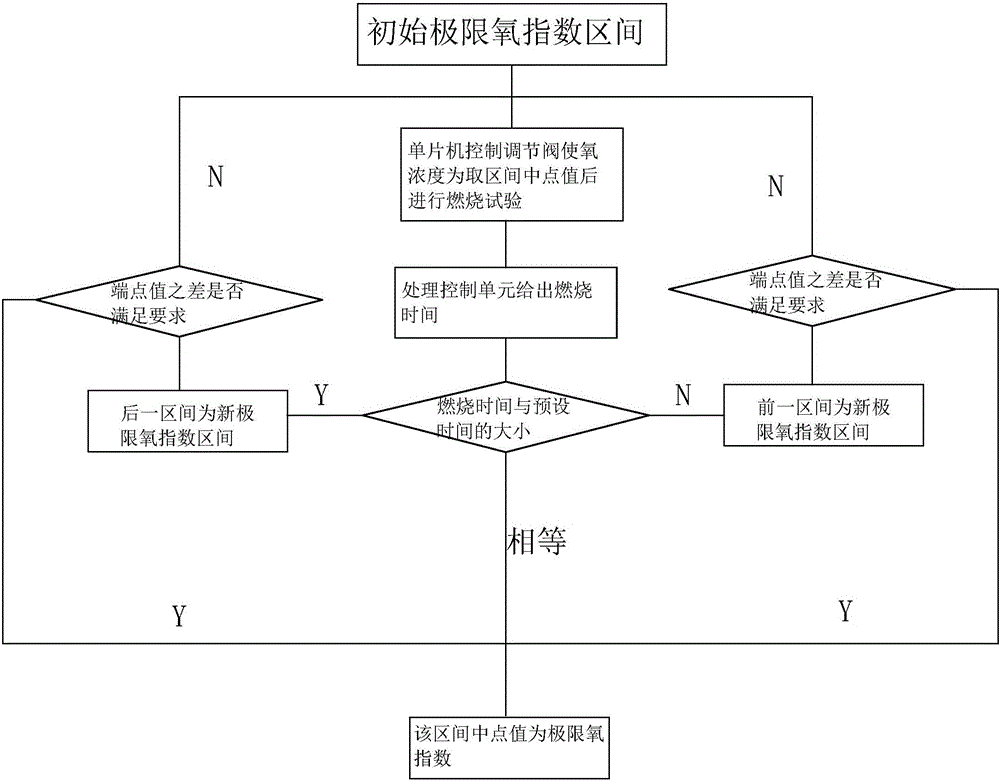

[0058] Embodiment two, see figure 2 and Figure 4 As shown, a control method of a building material oxygen index test control system comprises the following steps,

[0059] Step 1. Measure the oxygen concentration in the oxygen index meter 8 through the oxygen concentration detection unit 3 and output an oxygen concentration signal positively correlated with the oxygen concentration;

[0060] Step 2. Use the flame detection unit 2 to detect whether the sample in the combustion tank 4 is burning. When the flame generated during combustion is detected, a timing signal is output. When the flame generated during combustion is not detected, a cut-off signal is output;

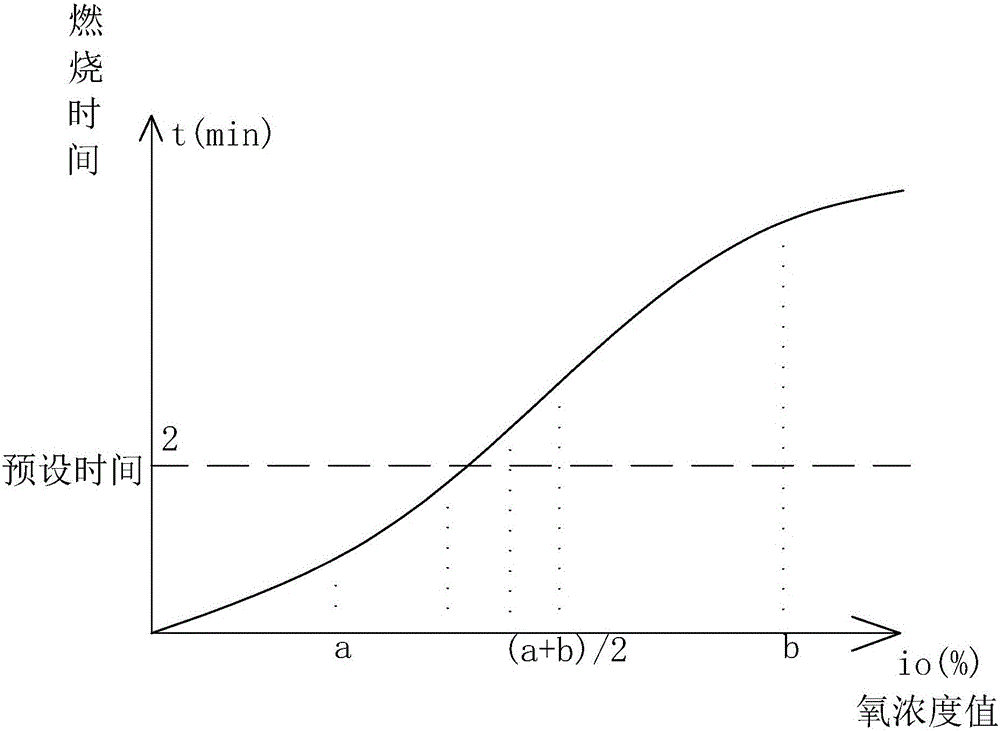

[0061] Step 3, by processing the control unit 1, start timing in response to the timing signal, and stop timing in response to the cut-off signal, so as to obtain the combustion time of a combustion test, and compare the combustion time with its internal preset time of 2 minutes;

[0062] When the combustion time...

Embodiment 3

[0068] Embodiment 3. A control method for a building material oxygen index test control system

[0069] The difference between the third embodiment and the second embodiment is that the adjustment methods are different when determining the initial limit oxygen index interval, the processing control unit 1 instructs the control element 5 to increase the oxygen concentration by a fixed increment or decrease the oxygen concentration by a fixed decrement to reach the initial limit oxygen index interval. Limiting oxygen index range.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com