System and method for fault diagnosis of blast furnace

A fault diagnosis system and fault diagnosis technology, applied in the field of blast furnace fault diagnosis, can solve problems such as unsatisfactory diagnosis effect and complex process, achieve excellent fault diagnosis performance and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

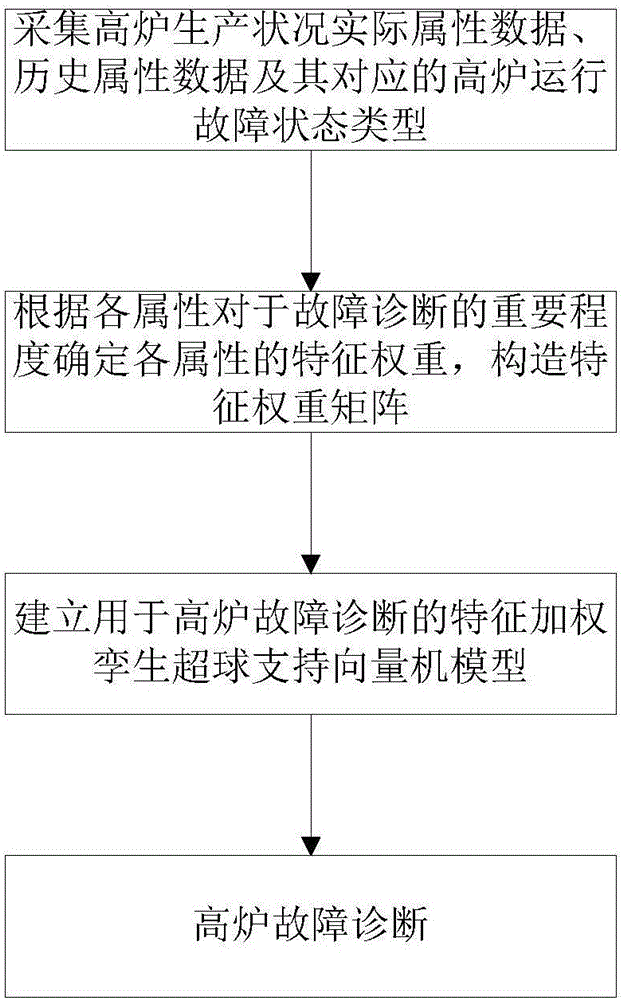

[0026] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0027] In this embodiment, the attribute data includes: air volume (m3 / min), wind pressure (Pa), top pressure (MPa), pressure difference, air permeability, top temperature (including four-point temperature), cross temperature measurement (including center and Edge, the unit is °C), material speed (unit is batch / hour), Si content, physical heat (unit is °C). Types of fault status, including: cooling, heating, suspension, collapse.

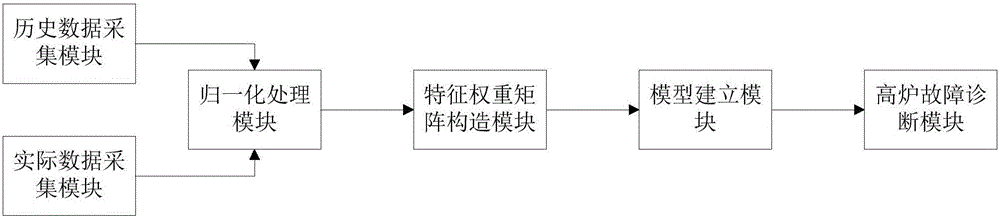

[0028] A blast furnace fault diagnosis system, such as figure 1 Shown, including:

[0029] Historical data collection module: Collect historical attribute data of blast furnace production status and its corresponding blast furnace operation fault status type.

[0030] Actual data collection module: Collect actual attribute data of blast furnace production status.

[0031] Feature weight matrix construction module: Determi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com