A blast furnace fault diagnosis system and method

A blast furnace and operation failure technology, applied in general control system, control/adjustment system, test/monitoring control system, etc., can solve problems such as unsatisfactory diagnosis effect and complex process, achieve excellent fault diagnosis performance and improve accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

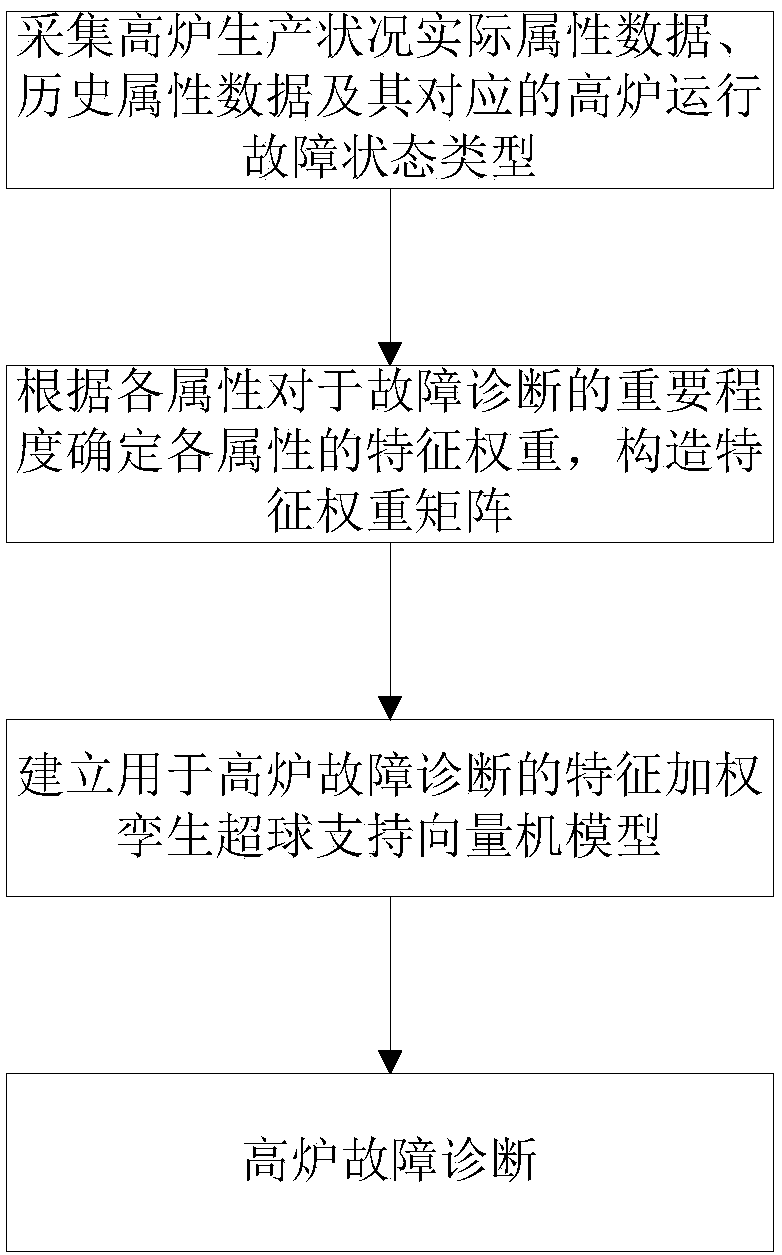

[0026] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0027] In this embodiment, the attribute data includes: air volume (m3 / min), wind pressure (Pa), top pressure (MPa), pressure difference, air permeability, top temperature (including four-point temperature), cross temperature measurement (including center and Edge, the unit is °C), material speed (unit is batch / hour), Si content, physical heat (unit is °C). Types of fault conditions include: cooling, heating, suspension, and collapse.

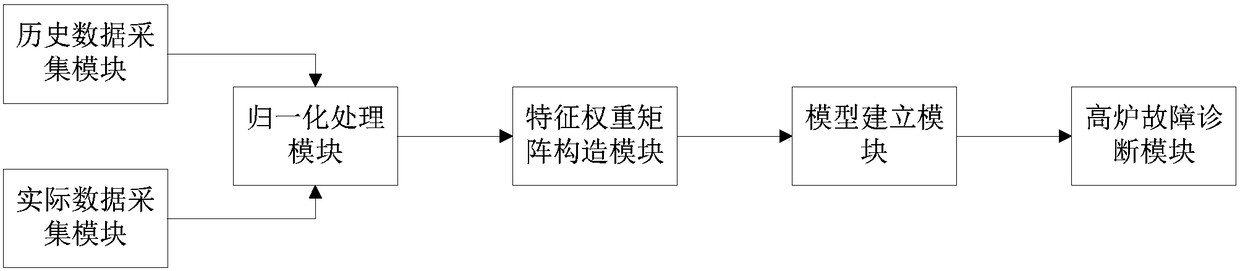

[0028] A blast furnace fault diagnosis system, such as figure 1 Shown, including:

[0029] Historical data collection module: Collect historical attribute data of blast furnace production status and its corresponding blast furnace operation fault status type.

[0030] Actual data collection module: Collect actual attribute data of blast furnace production status.

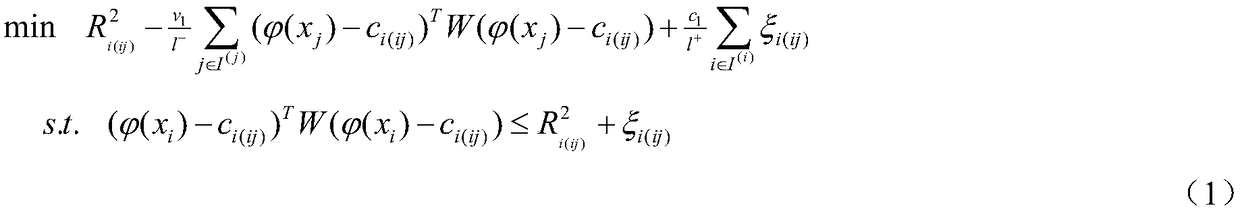

[0031] Feature weight matrix construction module: De...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com