A Compression Type High Current Temperature Controller

A high-current, thermostat technology, applied in the direction of thermal switch components, etc., can solve problems such as large electrical resistance of resistance, and achieve the effect of compressing the overall structure height, stable operation, and simplifying the number of structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

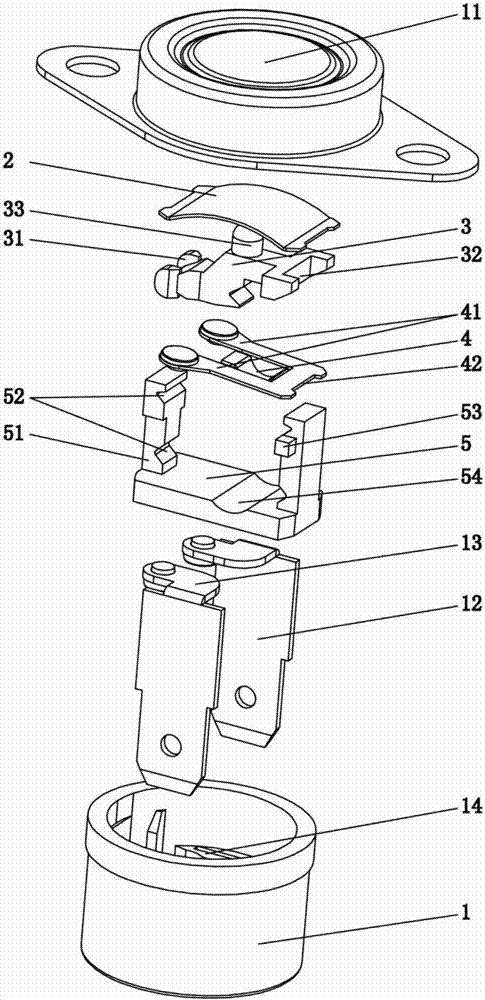

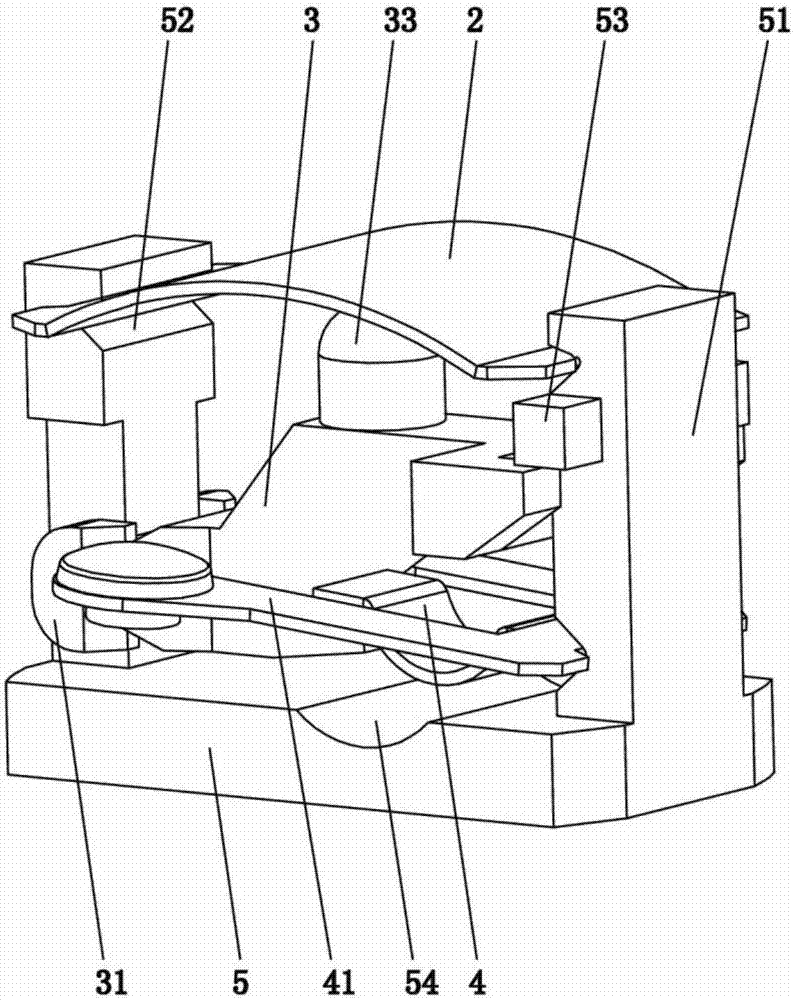

[0018] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

[0019] Such as figure 1 As shown, a compression-type high-current thermostat according to the present invention includes a casing 1 with an opening at the upper end, a temperature-sensing cover 11 is provided on the upper port of the casing 1, and a lower bottom plate of the casing 1 Two electrical terminals 12 are pierced. The housing 1 is provided with an action mechanism. The action mechanism includes a heat-sensitive sheet 2, a linkage arm 3 and a tongue piece 4 with extension and elasticity. The heat-sensitive sheet 2 is fixed on the shell. In the upper port of the body 1 and in a conflicting connection with the temperature-sensitive cover 11; the linkage arm 3 is arranged horizontally and the fixed end of the linkage arm 3 is hinged with the housing 1, and the fixed end of the tongue 4 is matched with the housing 1 Connection, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com