Extrusion bundling device of automatic straw bundling machine

A bundling device and automatic technology, applied in the direction of bundling, harvesting machines, crop processing machines, etc., can solve the problems of short life, frequent replacement and maintenance, damage, etc., achieve long service life, less wear and collision, and reduce the number of structures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

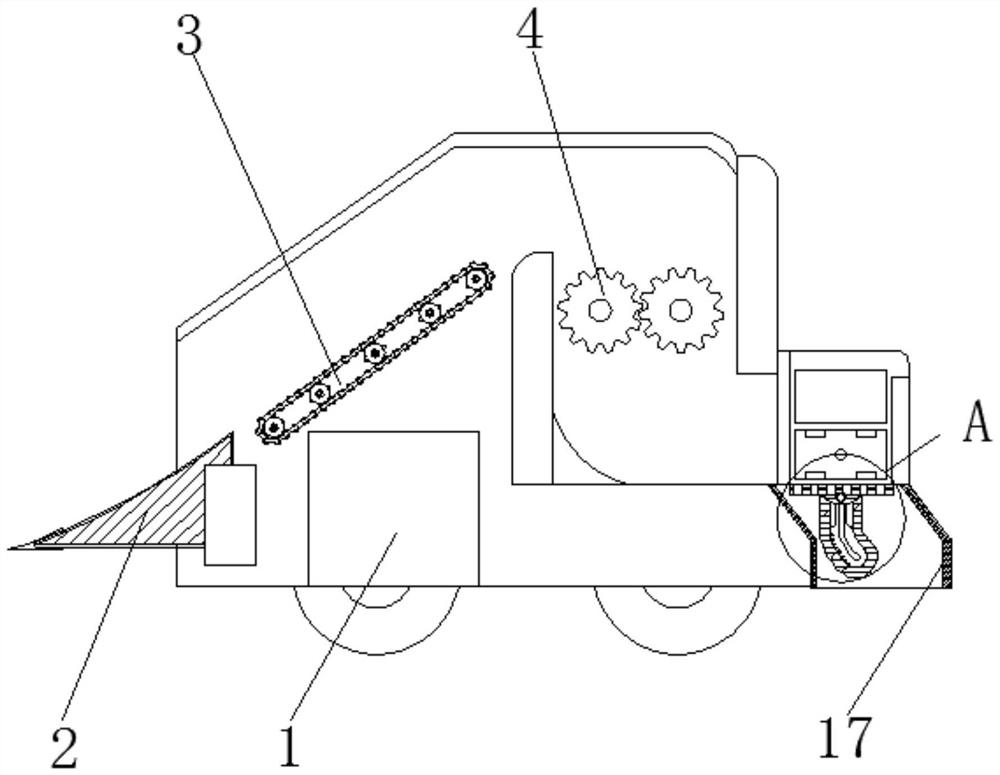

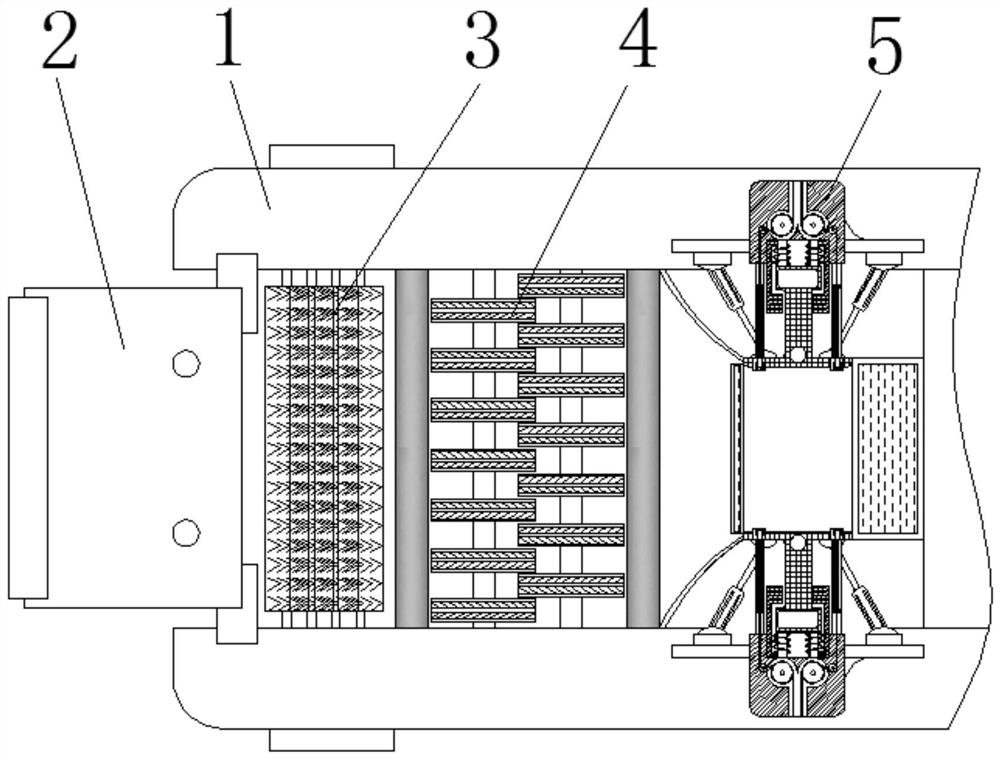

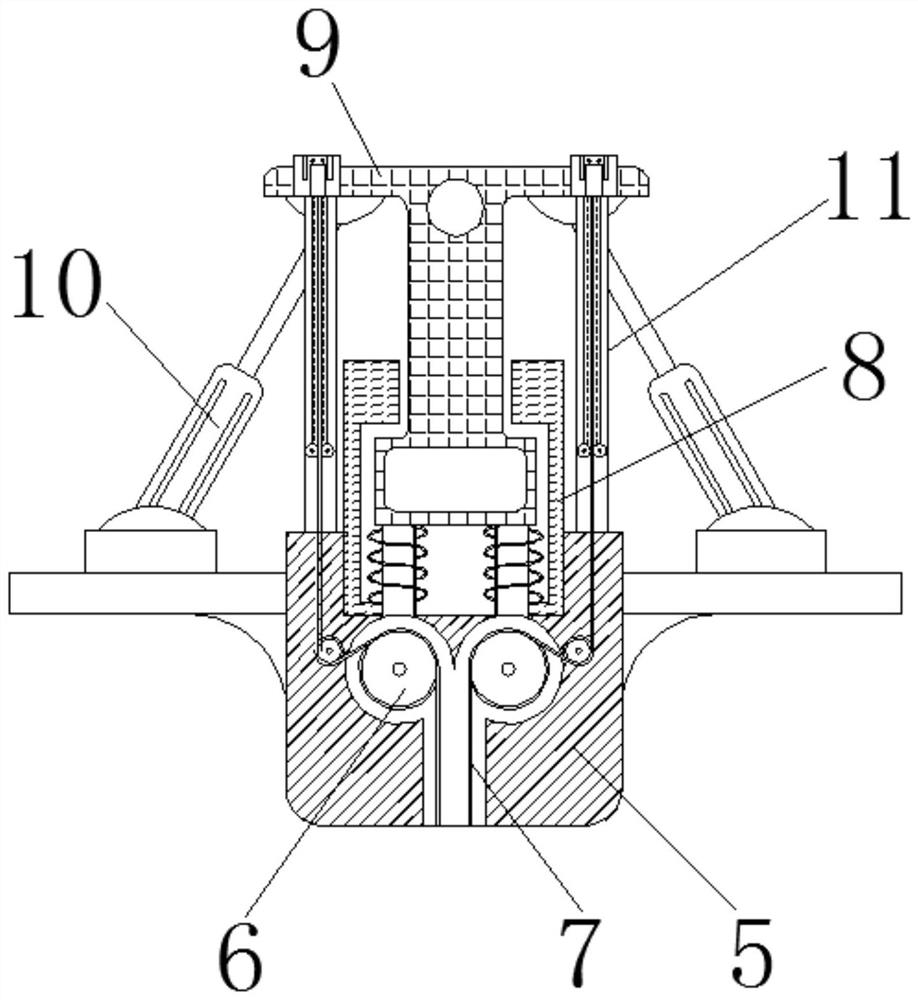

[0025] See Figure 1-5 , An extrusion of a straw automatic baler, including the locomotive case 1, and the left side of the locomotive case 1 is provided with a shovel 2, and the right side of the push shovel 2 is provided with a ratchet conveyor belt 3, and the right side of the ratchet conveyor belt 3. The double-axis pulverizer 4 is provided, and the lower right of the biaxial pulverizer 4 is provided with two extrusion mount 5, and the inside of the extrusion mount 5 is provided with a tape wheel 6, and the outer portion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com