A tension-resistant support type anti-floating anchor structure

An anti-floating anchor and support type technology, which is applied in the direction of foundation structure engineering, construction, sheet pile wall, etc., can solve the problem of low adhesion, achieve the effect of improving quality, increasing contact area and shortening length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

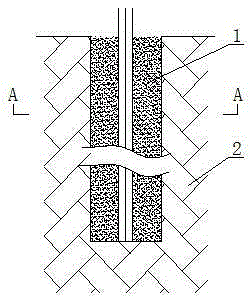

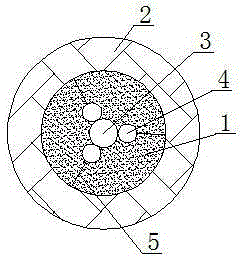

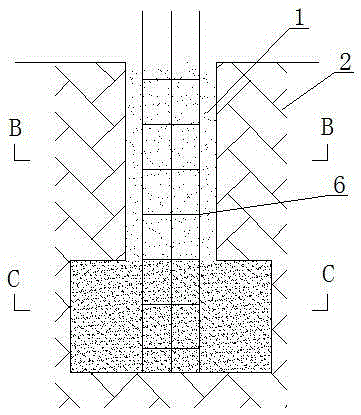

[0038] The tensile support type anti-floating anchor structure of this embodiment includes an anchor rod, a grouting body and an anchor hole opened on the rock and soil body, one end of the anchor rod extends into the anchor hole, and the grouting body is filled in the anchor hole Bonded with the rock and soil as a whole, the aperture at the lower end of the anchor hole is larger than the aperture at the upper end of the anchor hole; the anchor rod includes a fixed bracket, and the outer circumference of the fixed bracket is provided with at least one anchor steel bar, and the outer circumference of the anchor bar steel bar is provided with The binding bracket; the anchor rod steel bar is fixed between the fixed bracket and the binding bracket.

Embodiment 2

[0040] The tensile support type anti-floating anchor structure of this embodiment includes an anchor rod, a grouting body and an anchor hole opened on the rock and soil body, one end of the anchor rod extends into the anchor hole, and the grouting body is filled in the anchor hole Bonded with the rock and soil as a whole, the aperture at the lower end of the anchor hole is larger than the aperture at the upper end of the anchor hole; the anchor rod includes a fixed bracket, and the outer circumference of the fixed bracket is provided with three anchor bars evenly arranged, and the outer circumference of the anchor bar is sleeved There is a binding bracket; the anchor rod steel bar is fixed between the fixed bracket and the binding bracket.

Embodiment 4

[0042] The tensile support type anti-floating anchor structure of this embodiment includes an anchor rod, a grouting body and an anchor hole opened on the rock and soil body, one end of the anchor rod extends into the anchor hole, and the grouting body is filled in the anchor hole Bonded with the rock and soil as a whole, the aperture at the lower end of the anchor hole is larger than the aperture at the upper end of the anchor hole; the anchor rod includes a fixed bracket, and the outer circumference of the fixed bracket is provided with three anchor bars evenly arranged, and the outer circumference of the anchor bar is sleeved There is a binding bracket; the anchor rod steel bar is fixed between the fixed bracket and the binding bracket.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com